14.8 Rover MEMS - MPi/SPi

Turbocharger

Referto Chapter 2 fora detailed description

of turbocharger operation. An intercooler,

which is a kind of air radiator, for cooling is

used in Rover turbo models. Boost control is

controlled by the ECMso that maximum use

is made of the turbo during appropriate

operating conditions.

Air by-pass (turbo models)

Turbo lag is reduced on Rover turbo

models by use of an air by-pass valve. A

sensing pipe connects the by-pass valvewith

the inlet manifold. When the turbine supplies

compressed air to the manifold, the

compressed air pushes upon the air by-pass

valve,and it remains shut. Duringdeceleration

or light load when the turbo is inactive, the

manifold contains depressed air (a vacuum)

and the depression willopen the air by-pass

valve. Airpressure from the impellerwheel is

circulated throughout the turbocharger

housing, and prevents a back pressure

forming. The turbine slows very little, and

turbo lag is much reduced when the

accelerator is re-applied.

6 Catalyticconverter and

emission control

'

1

1

I.

I

From January 1993, all new cars in the UK

are fitted with a catalyst as standard

equipment.

Adjustments

~

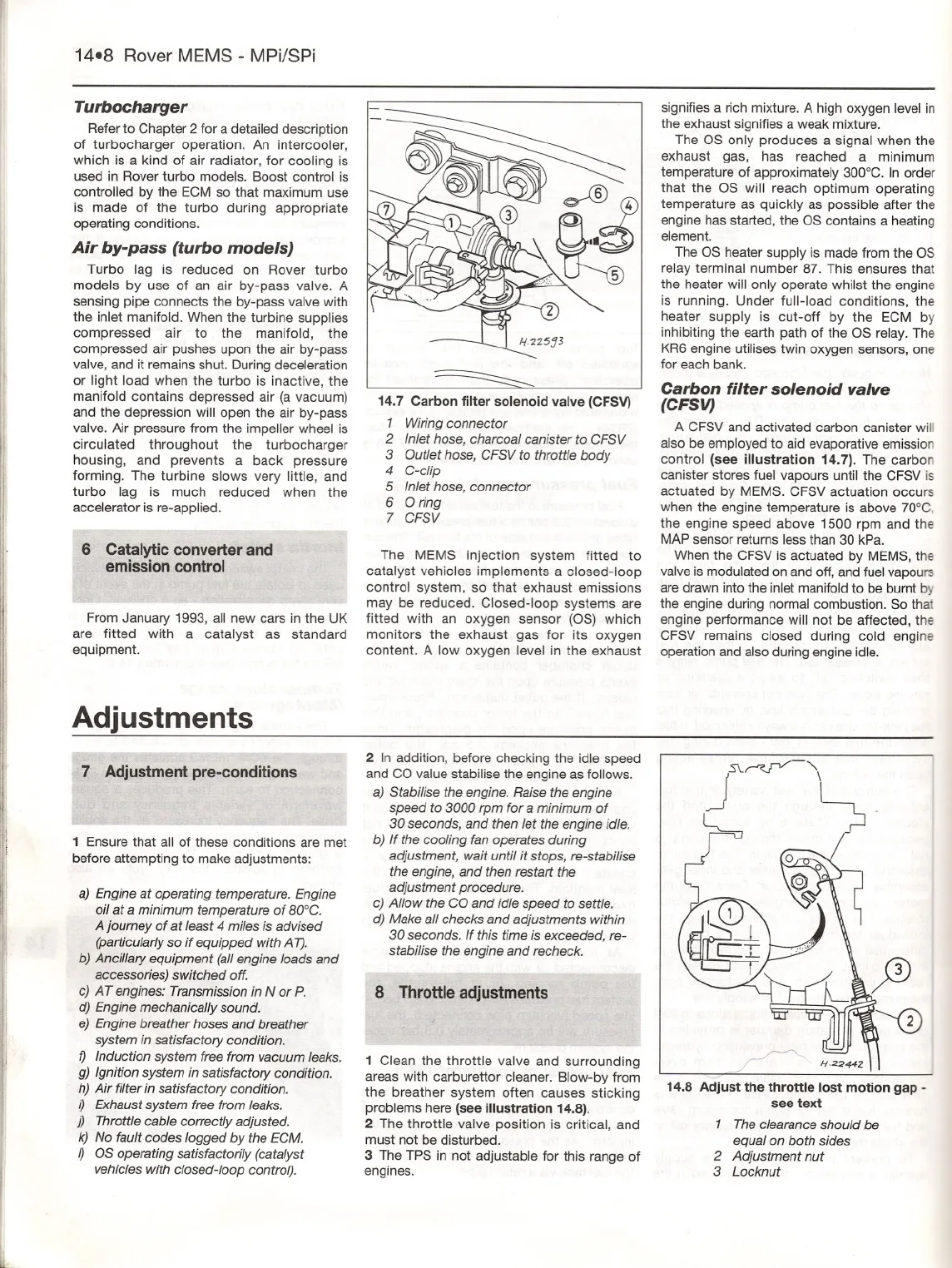

14.7 Carbon filter solenoid valve (CFSV)

1 Wiringconnector

2 Inlethose, charcoalcanister to GFSV

3 Outlethose, GFSVto throttlebody

4 G-cIip

5 Inlethose, connector

6 0 ring

7 GFSV

The MEMS injection system fitted to

catalyst vehicles implements a closed-loop

control system, so that exhaust emissions

may be reduced. Closed-loop systems are

fitted with an oxygen sensor (OS) which

monitors the exhaust gas for its oxygen

content. A low oxygen level in the exhaust

signifiesa rich mixture.A high oxygen levelin

the exhaust signifiesa weak mixture.

The OS only produces a signal when the

exhaust gas, has reached a minimum

temperature of approximately300°C. In order

that the OS will reach optimum operating

temperature as quickly as possible after the

engine has started, the OS contains a heating

element.

The OS heater supply is made from the OS

relay terminal number 87. This ensures that

the heater willonly operate whilst the engine

is running. Under full-load conditions, the

heater supply is cut-off by the ECM by

inhibitingthe earth path of the OS relay. The

KR6engine utilises twin oxygen sensors, one

for each bank.

Carbon filter solenoid valve

(CFSV)

A CFSVand activated carbon canister will

also be employed to aid evaporative emission

control (see illustration 14.7). The carbon

canister stores fuel vapours until the CFSVis

actuated by MEMS.CFSV actuation occurs

when the engine temperature is above 70°C,

the engine speed above 1500 rpm and the

MAPsensor returns less than 30 kPa.

When the CFSV is actuated by MEMS,the

valveis modulated on and off,and fuelvapours

are drawn into the inletmanifoldto be bumt by

the engine during normalcombustion. So that

engine performance willnot be affected, the

CFSV remains closed during cold engine

operation and also duringengine idle.

~

'I

I

~

7 Adjustmentpre-conditions

1 Ensure that all of these conditions are met

before attempting to make adjustments:

I

a) Engine at operating temperature. Engine

oilat a minimumtemperatureof aOOG.

Ajourney of at least 4 miles is advised

(particularly so if equipped with A1).

b) Ancillary equipment (allengine loads and

accessories) switched off.

c) AT engines: Transmission in N or P.

d) Engine mechanically sound.

e) Engine breather hoses and breather

system in satisfactory condition.

f) Induction system free from vacuum leaks.

g) Ignition system in satisfactory condition.

h) Air filter in satisfactory condition.

ij Exhaust system free from leaks.

j) Throttle cable correctly adjusted.

k) No fault codes logged by the EGM.

I) OS operating satisfactorily (catalyst

vehicles with closed-loop control).

.1

I

l

2 In addition, before checking the idle speed

and CO valuestabilise the engine as follows.

a) Stabilise the engine. Raise the engine

speed to 3000 rpm fora minimum of

30 seconds, and then let the engine idle.

b) Ifthe cooling fan operates during

adjustment, wait untilit stops, re-stabilise

the engine, and then restart the

adjustment procedure.

c) Allowthe GOand idlespeed to settle.

d) Make allchecks and adjustments within

30 seconds. If this time is exceeded, re-

stabilisethe engine and recheck.

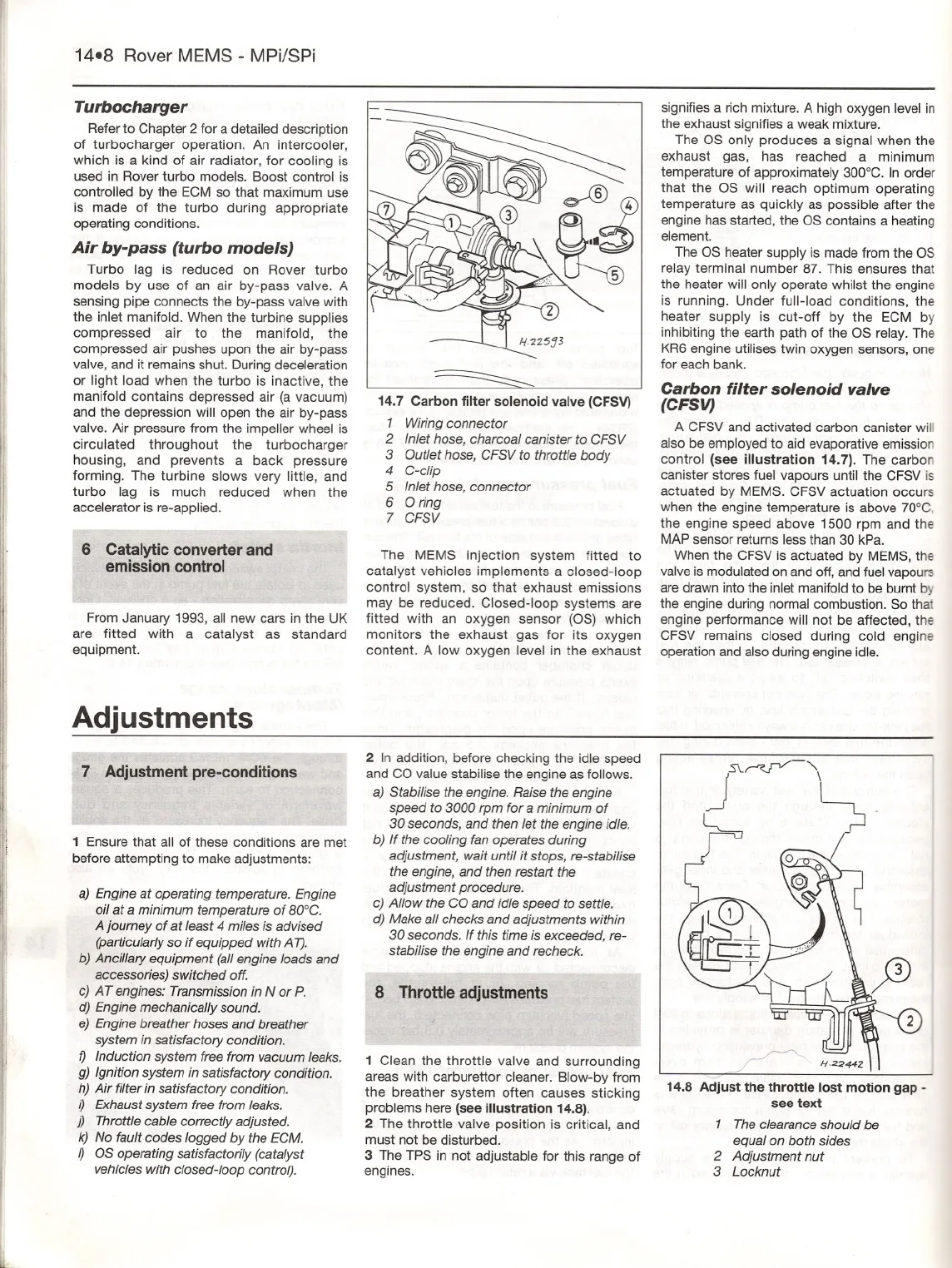

8 Throttleadjustments

1 Clean the throttle valve and surrounding

areas with carburettor cleaner. Blow-byfrom

the breather system often causes sticking

problems here (see illustration 14.8).

2 The throttle valve position is critical, and

must not be disturbed.

3 The TPS in not adjustable for this range of

engines.

JSC~-'I

14.8 Adjust the throttle lost motion gap -

see text

1 The clearanceshould be

equal on both sides

2 Adjustment nut

3 Locknut