Rover MEMS - MPi/SPi 14-11

.ECM

2 3 22 27 24 23 . 26

suppty

frommain

relay: t87

23164

" Stepper

motor

EOH1418

inj 1 inj2 inj3 inj4

14.12 Typical local wiring diagram:

injectors, stepper motor

14.13 Stepper motor multi-plug

pin numbers

7 Disconnect the ECM multi-plug (refer to

Warning No 3 in Reference)

8 Switch the ignition key 'on'.

9 Connect a jumper lead from ECM pin 4 to

battery earth (this energises the main relay

with the ECM disconnected).

10 Connect

a voltmeter between earth and

ECM pins 22, 2. 27 and 3 in turn. nbv should

be obtained.

11 If nbv is not obtained at one or more of

the ECM pins. check the continuity of the

wiring between the relevant ECM and stepper

motor pins.

12 If the stepper motor wiring is satisfactory.

check all voltage supplies and earth

connection~ to the ECM. If -the' voltage

supplies and earth connections are

satisfactory, the ECM is suspect."

--- - - -- -- - -

23 i!Manifold heater

(SPi engines only)

-- . ---

----..--

1 Referto the notes at the start of Section 11.

and referto the relevant Section of Chapter 4.

2 Make tests when the engine coolant

temperature is less than 75°C. Note: If the

engine is hot. a variable potentiometer could

be connected to the CTS multi-plug so that a

cold engine could be simulated.

3 If a FCR is available. the manifold heater

relaycan be"actuated via the serial port. This

liould prove the integrity of the relay and

associated wiring.

14.14 Probing for nbv at the

ECMmulti-plug

- -.. - - -- - -.--

24 ECMvoltage supplies

and earths

1 Refer to the notes at the start of Section 11.

and refer to the relevant Section of Chapter 4

(see illustration 14.14). .

2 In addition to relay drivers for the main relay

and pump relay. relay drivers may be available

for the manifold heater and OS relays.

25 Inertia switch

1 Refer to the notes at the start of Section 11.

and refer to the relevant Section of Chapter 4.

2 Montego models only: check the ballast

resistor by-pass.

3 The inertia switch may be located behind

the radio (early models) or in the engine

compartment. close to the bulkhead.

ECM

29 36

18 72142028

EARTH

f

--.

screoen ~ ---

,..---

~ ::-H

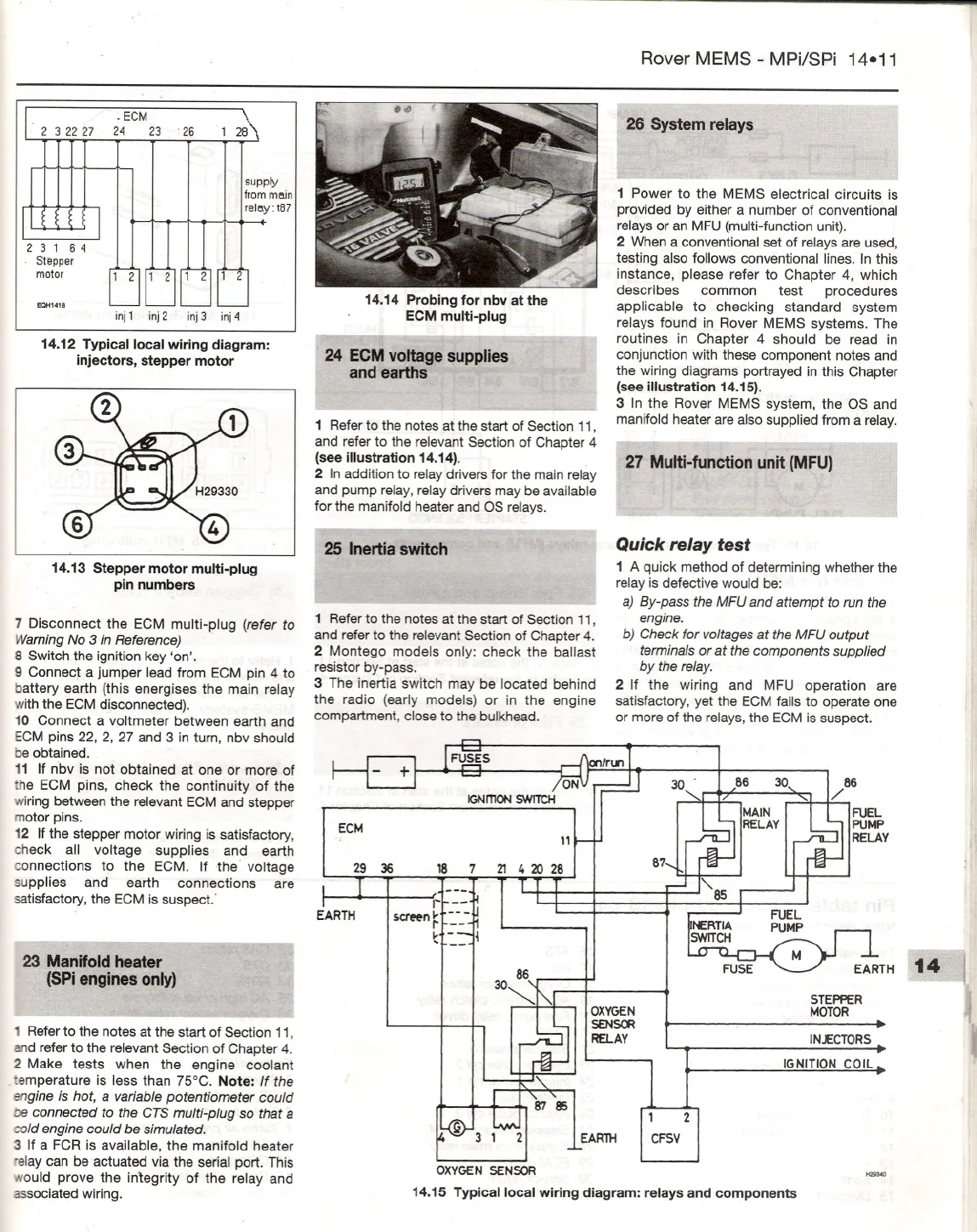

, 26 System relays

.

.

.I

1 Power to the MEMS electrical circuits is

provided by either a number of conventional

relays or an MFU (multi-function unit).

2 When a conventional set of relays are used.

testing also follows conventional lines. In this

instance. please refer to Chapter 4, which

describes common test procedures

applicable to checking standard system

relays found in Rover MEMS systems. The

routines in Chapter 4 should be read in

conjunction with these component notes and

the wiring diagrams portrayed in this Chapter

(see illustration 14.15).

3 In the Rover MEMS system. the OS and

manifold heater are also supplied from a relay.

- _l1li'- 011-

27 Multi-function unit (MFU) ,

J

Quick relay test

1 Aquick method of determining whether the

relay is defective would be:

a) By-pass the MFU and attempt to run the

engine.

b) Check for voltages at the MFU output

terminals or at the components supplied

by the relay.

2 If the wiring and MFU operation are

satisfactory, yet the ECM fails to operate one

or more of the relays, the ECM is suspect.

86 30.

STEPPER

MOTOR

IN.£CTORS

IGNITION COIL

I,

1 2

CFSV

OXYGEN

SENSOR

14.15 Typical local wiring diagram: relays and components