Rover MEMS - MPi/SPi 14-7

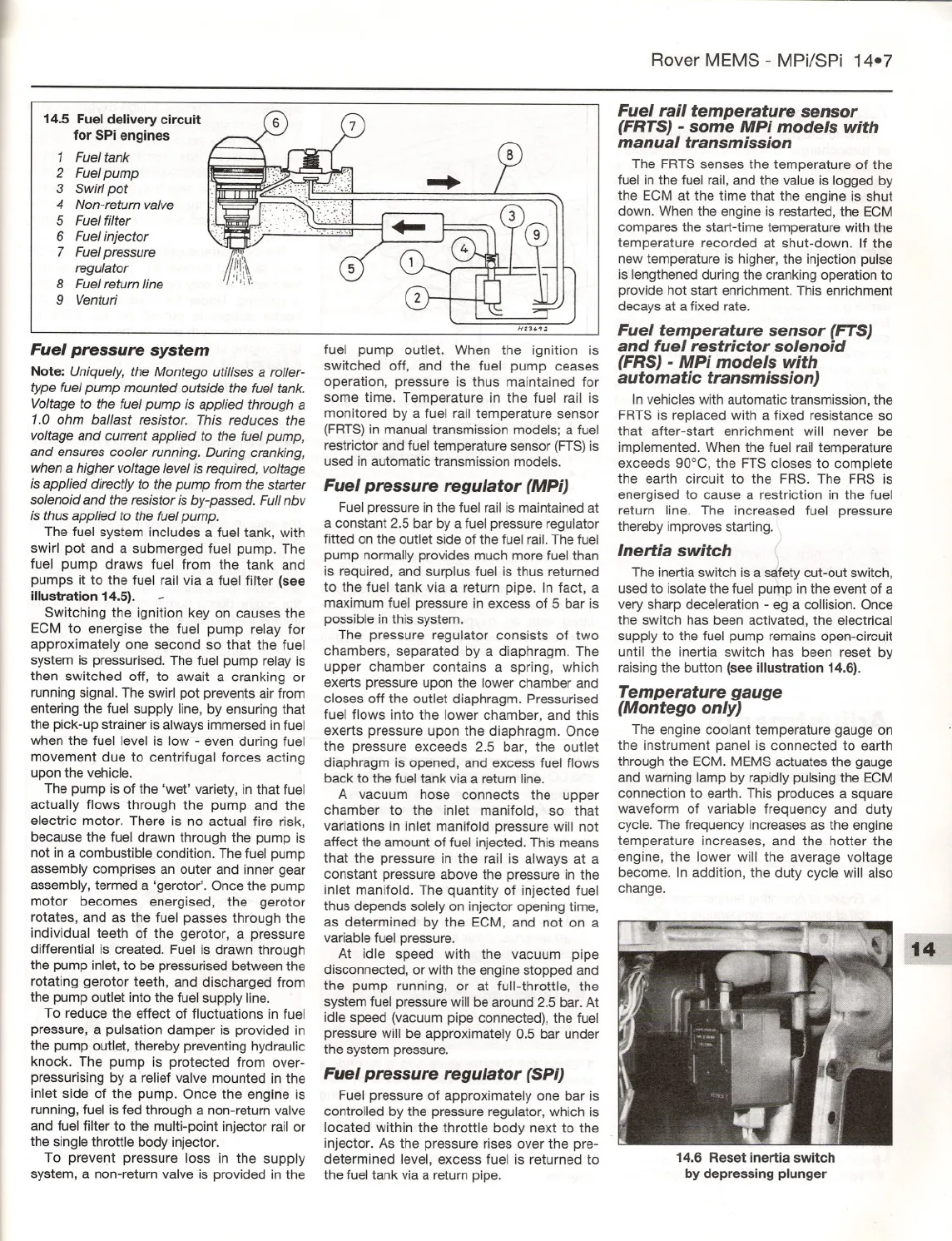

14.5 Fuel delivery circuit

for SPi engines

1

Fuel tank

2 Fuelpump

3 Swirlpot

4 Non-returnvalve

5 Fuelfilter

6 Fuelinjector

7 Fuelpressure

regulator

8 Fuelreturnline

9 Venturi

Fuel pressure system

Note: Uniquely, the Montego utilises a roller-

typefuel pump mounted outside the fuel tank.

Voltageto the fuel

pump is applied through a

1.0 ohm ballast resistor. This reduces the

voltage and current applied to the fuel pump,

and ensures cooler running. Duringcranking,

when a higher voltage level is required, voltage

is applied directlyto the pump from the starter

solenoid and the resistor is by-passed. Full nbv

is thus applied to the fuel pump.

The fuel system includes a fuel tank, with

swirl pot and a submerged fuel pump. The

fuel pump draws fuel from the tank and

pumps it to the fuel rail via a fuel filter (see

illustration 14.5). -

Switching the ignition key on causes the

ECM to energise the fuel pump relay for

approximately one second so that the fuel

system is pressurised. The fuel pump relay is

then switched off, to await a cranking or

running signal. The swirl pot prevents air from

entering the fuel supply line, by ensuring that

the pick-up strainer is always immersed in fuel

when the fuel level is low - even during fuel

movement due to centrifugal forces acting

upon the vehicle.

The pump is of the 'wet' variety, in that fuel

actually flows through the pump and the

electric motor. There is no actual fire risk,

because the fuel drawn through the pump is

not in a combustible condition. The fuel pump

assembly comprises an outer and inner gear

assembly, termed a 'gerotor'. Once the pump

motor becomes energised, the gerotor

rotates, and as the fuel passes through the

individual teeth of the gerotor, a pressure

differential is created. Fuel is drawn through

the pump inlet, to be pressurised between the

rotating gerotor teeth, and discharged from

the pump outlet into the fuel supply line.

To reduce the effect of fluctuations in fuel

pressure, a pulsation damper is provided in

the pump outlet, thereby preventing hydraulic

knock. The pump is protected from over-

pressurising by a'relief valve mounted in the

inlet side of the pump. Once the engine is

running, fuel is fed through a non-return valve

and fuel filter to the multi-point injector rail or

the single throttle body injector.

To prevent pressure loss in the supply

system, a non-return valve is provided in the

fuel pump outlet. When the ignition is

switched off, and the fuel pump ceases

operation, pressure is thus maintained for

some time. Temperature in the fuel rail is

monitored by a fuel rail temperature sensor

(FRTS)in manual transmission models; a fuel

restrictor and fuel temperature sensor (FTS)is

used in automatic transmission models.

Fuel pressure regulator (MPi)

Fuel pressure in the fuel rail is maintained at

a constant 2.5 bar by a fuel pressure regulator

fitted on the outlet side of the fuel rail. The fuel

pump normally provides much more fuel than

is required, and surplus fuel is thus returned

to the fuel tank via a return pipe. In fact, a

maximum fuel pressure in excess of 5 bar is

possible in this system.

The pressure regulator consists of two

chambers, separated by a diaphragm. The

upper chamber contains a spring, which

exerts pressure upon the lower chamber and

closes off the outlet diaphragm. Pressurised

fuel flows into the lower chamber, and this

exerts pressure upon the diaphragm. Once

the pressure exceeds 2.5 bar, the outlet

diaphragm is opened, and excess fuel flows

back to the fuel tank via a return line.

A vacuum hose connects the upper

chamber to the inlet manifold, so that

variations in inlet manifold pressure will not

affect the amount of fuel injected. This means

that the pressure in the rail is always at a

constant pressure above the pressure in the

inlet manifold. The quantity of injected fuel

thus depends solely on injector opening time,

as determined by the ECM, and not on a

variable fuel pressure.

At idle speed with the vacuum pipe

disconnected, or with the engine stopped and

the pump running, or at full-throttle, the

system fuel pressure will be around 2.5 bar. At

idle speed (vacuum pipe connected), the fuel

pressure will be approximately 0.5 bar under

the system pressure.

Fuel pressure regulator (SPi)

Fuel pressure of approximately one bar is

controlled by the pressure regulator, which is

located within the throttle body next to the -

injector. As the pressure rises over the pre-

determined level, excess fuel is returned to

the fuel tank via a return pipe.

Fuel rail temperature sensor

(FRTS)

-some MPi models with

manual transmission

The FRTS senses the temperature of the

fuel in the fuel rail, and the value is logged by

the ECM at the time that the engine is shut

down. When the engine is restarted, the ECM

compares the start-time temperature with the

temperature recorded at shut-down. If the

new temperature is higher, the injection pulse

is lengthened during the cranking operation to

provide hot start enrichment. This enrichment

decays at a fixed rate.

Fuel temperature sensor (FTS)

and fuel restrictor solenoid

(FRS) -MPi models with

automatic transmission)

In vehicles with automatic transmission, the

FRTS is replaced with a fixed resistance so

that after-start enrichment will never be

implemented. When the fuel rail temperature

exceeds 90°C, the FTS closes to complete

the earth circuit to the FRS. The FRS is

energised to cause a restriction in the fuel

return line. The increased fuel pressure

thereby improves starting.

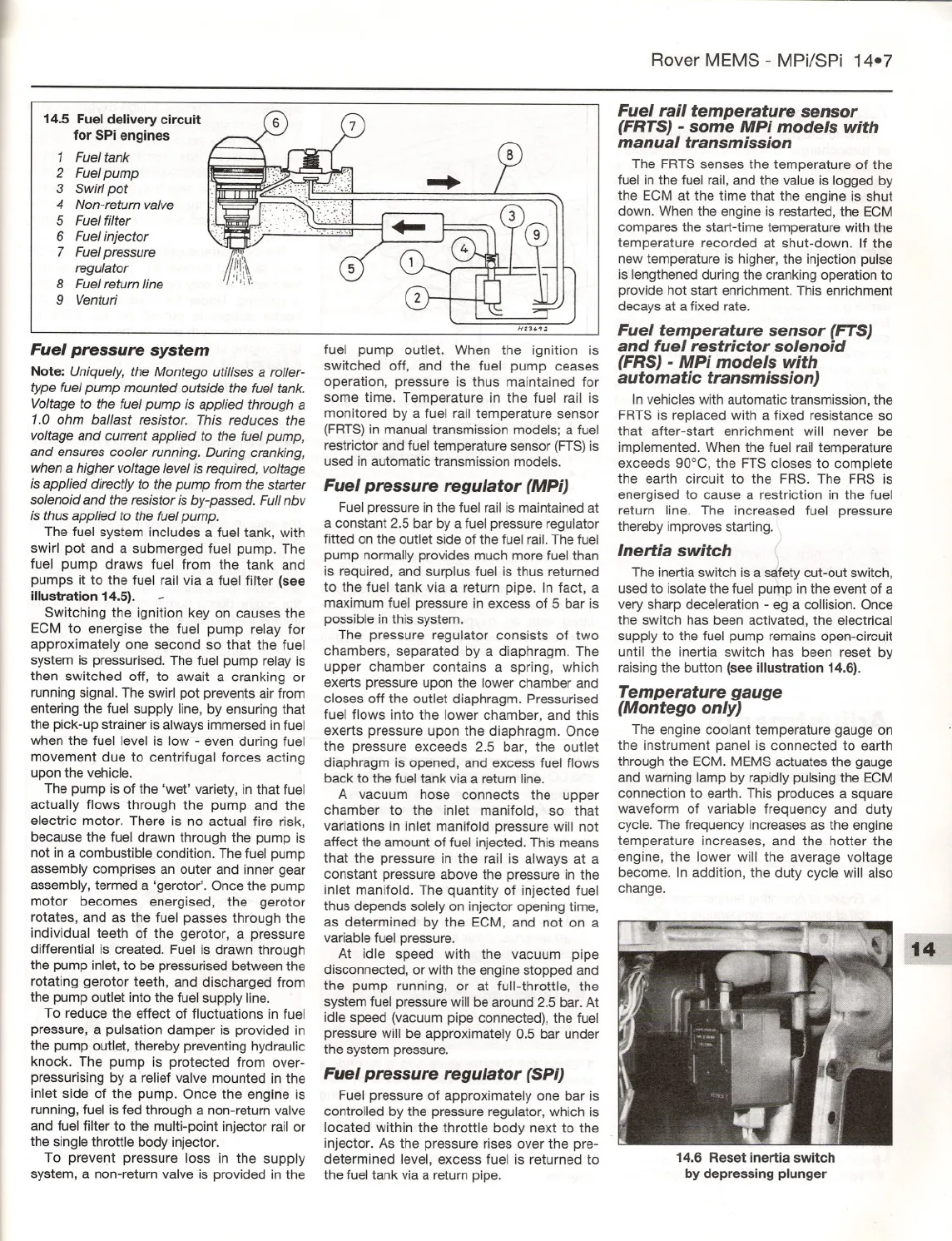

Inertia switch

The inertia switch is a safety cut-out switch,

used to isolate the fuel pump in the event of a

very sharp deceleration - eg a collision.Once

the switch has been activated, the electrical

supply to the fuel pump remains open-circuit

until the inertia switch has been reset by

raising the button (see illustration 14.6).

Temperature gauge

(Montego only)

The engine coolant temperature gauge on

the instrument panel is connected to earth

through the ECM. MEMS actuates the gauge

and warning lamp by rapidly pulsing the ECM

connection to earth. This produces a square

waveform of variable frequency and duty

cycle. The frequency increases as the engine

temperature increases, and the hotter the

engine, the lower will the average voltage

become. In addition, the duty cycle will also

change.

14.6 Reset inertia switch

by depressing plunger