P/N: 4FT020-010

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

07FEB02 V2.0

(99-01SuperDuty(4FT V2.0))

11

10. MOUNTING BRACKET BRACKET & SUPERCHARGER INSTALLATION, cont’d.

11. AIR INLET ASSEMBLY

J. Thread the 1/8" NPT x #4 x 90° fitting into the oil

feed fitting on the supercharger. Rotate the

fitting down. Connect the oil feed line to the #4

fitting and tighten. Use only clean engine oil on

the oil feed fittings threads.

K. Secure the oil feed line away from heat and

abrasion with the provided tie wraps.

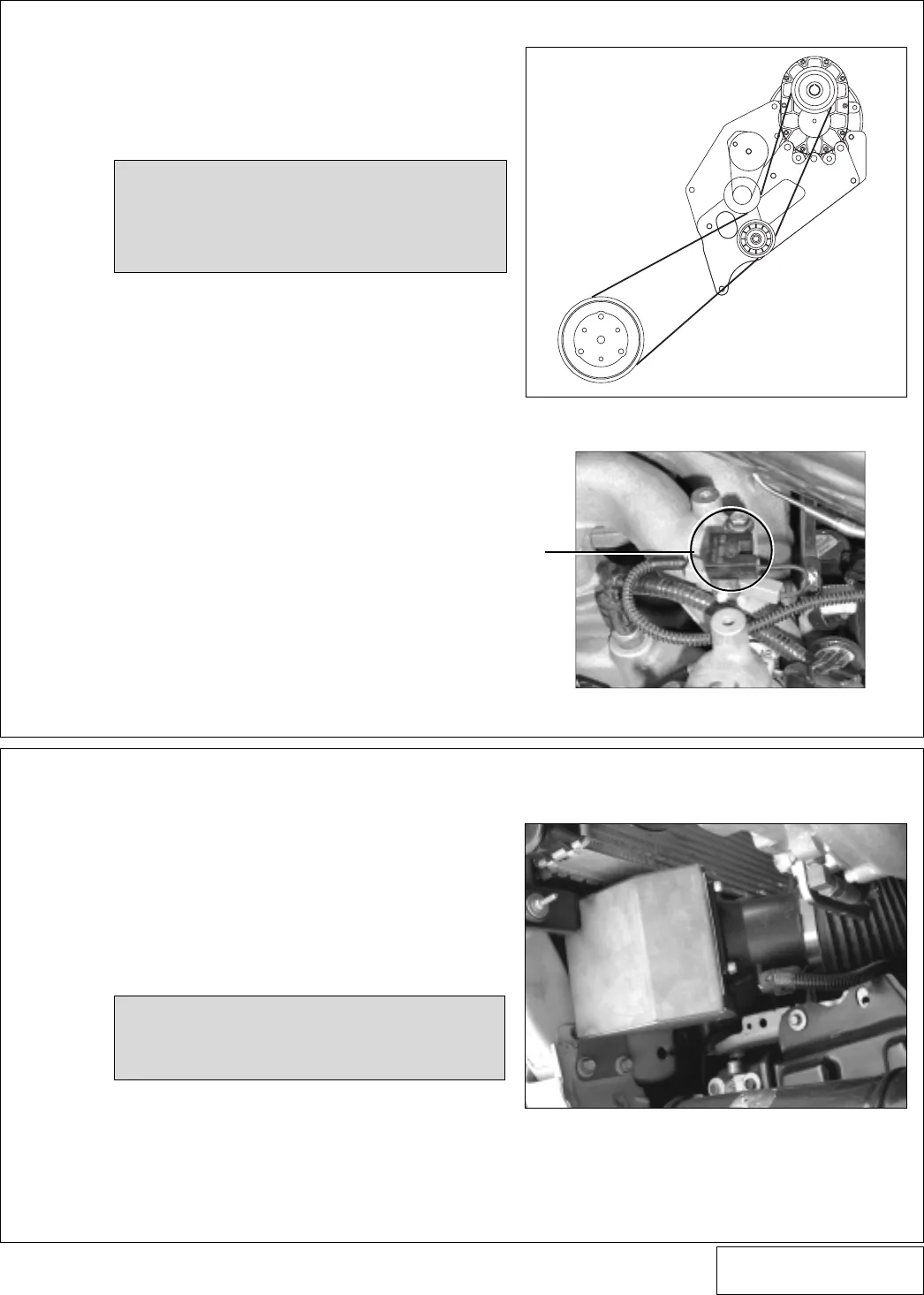

L. Route the supplied supercharger drive belt

around the crank pulley, supercharger drive

pulley and grooved idler. Using a 1/2" drive

breaker bar, rotate the spring tensioner clock-

wise and align the belt. (See

Fig 10-d

.)

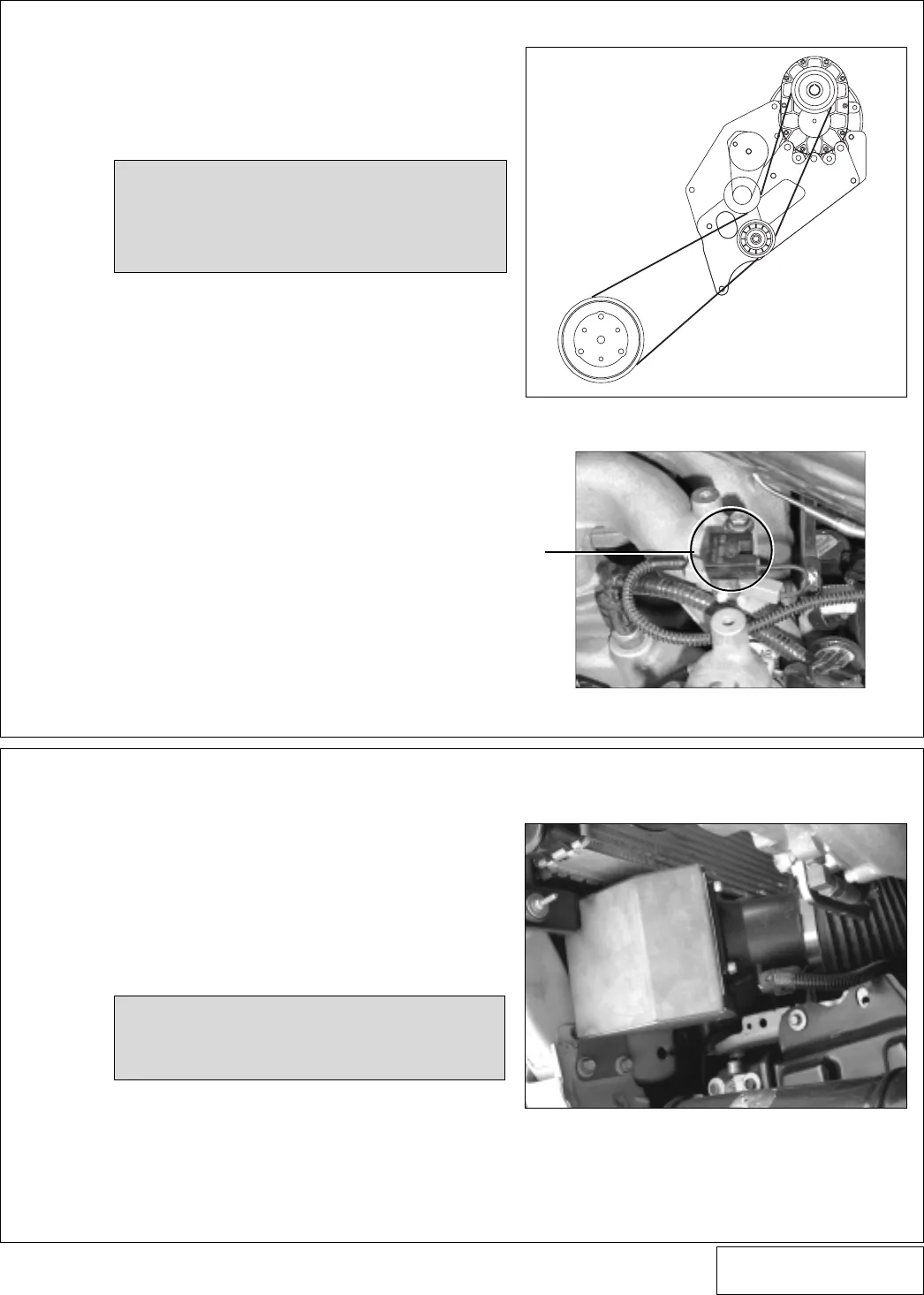

M. Relocate the capacitor (previously attached to

the upper front cover mounting stud) to one of

the screws securing the water neck or upper

manifold. (See

Fig 10-e

.)

A. Attach the MAF meter to the MAF bracket using

the supplied 1/4” hardware. Slide the air filter

onto the tube of the MAF bracket. Using a 5/16”

nut driver or socket, reach in through one of the

Ø5/8” holes and tighten the hose clamp. Cover

the holes with the provided finishing plugs.

B. Install the MAF assembly onto the driver’s side

of the core support using the factory hardware.

(See

Fig. 11-a

.)

C. Reconnect the MAF wiring connector to the

MAF meter.

D. Install the Ø3.5” x 2” silicone sleeve and #56

hose clamps onto the supercharger inlet. Install

the cast aluminum inlet duct into the silicone

sleeve and tighten the hose clamps.

NOTE: The thick rubber mat may need to be

unsnapped and folded over toward the

radiator to allow proper mounting of

the MAF assembly.

Fig. 10-d

Fig. 10-e

See Appendix A-6

for detail view.

?

CAPACITOR

Fig. 11-a

NOTE: Do not use any type of sealant on the

oil feed fittings. It may become dis-

lodged and clog the oil feed orifice,

causing premature failure of the super-

charger and voiding your warranty.