UPDATED: 6/2014 Instruction Manual IM-268-11 2014© Bally Refrigerated Boxes, Inc. 6

7. Installing Multi-Compartment Walk-Ins

A. The most common arrangement for a Walk-In is a two compartment

cooler/freezer combination. Installation of panels in this situation is the same as

described above. The use of a “Breaker” or “Tee” panel is used to separate the

different compartments. These panels will be either 23” or 46”; typically the

verticals are the opposite of the ceilings and floors.

B. The Partition Wall will have at least two special panels referred to as P-1 and P-2.

The panel widths are either 7.6” or 19.1” and are marked with a special blue

sticker that corresponds to the drawing. The P-2 panels are double tongued (has

hook pockets on both sides) which allows for final locking of the partition wall.

C. In large multi-compartment Walk-Ins, (three compartments or more) it is very

important to control the alignment of the panels and make sure if there is any

growth in the vertical panels that they are growing at the same rate as the ceiling

and floors. A quick and accurate way to check for correct alignment is to

measure the distance from the edge of the ceiling to the nearest vertical panel

joint. This measurement must be 11½”; it must be maintained at every joint to

assure proper assembly of the Walk-In. See Figure 10. In these instances we

recommend that after the floors are placed and leveled that the center most

partition be the starting point and to work toward either end of the box.

D. Look at the plan view and take special note of which side of the panels the

wrench hold are on. If there is not a door in the partition wall the panels will lock

to ceiling and floors in either orientation. An error on the partition will could cost

many man hours to correct. The entire box will most likely have to be taken

down to correct this error because condensation will occur. As a general rule of

thumb, the wrench holes should always be on the colder compartment side,

usually the freezer.

Part Three: Other Important Information

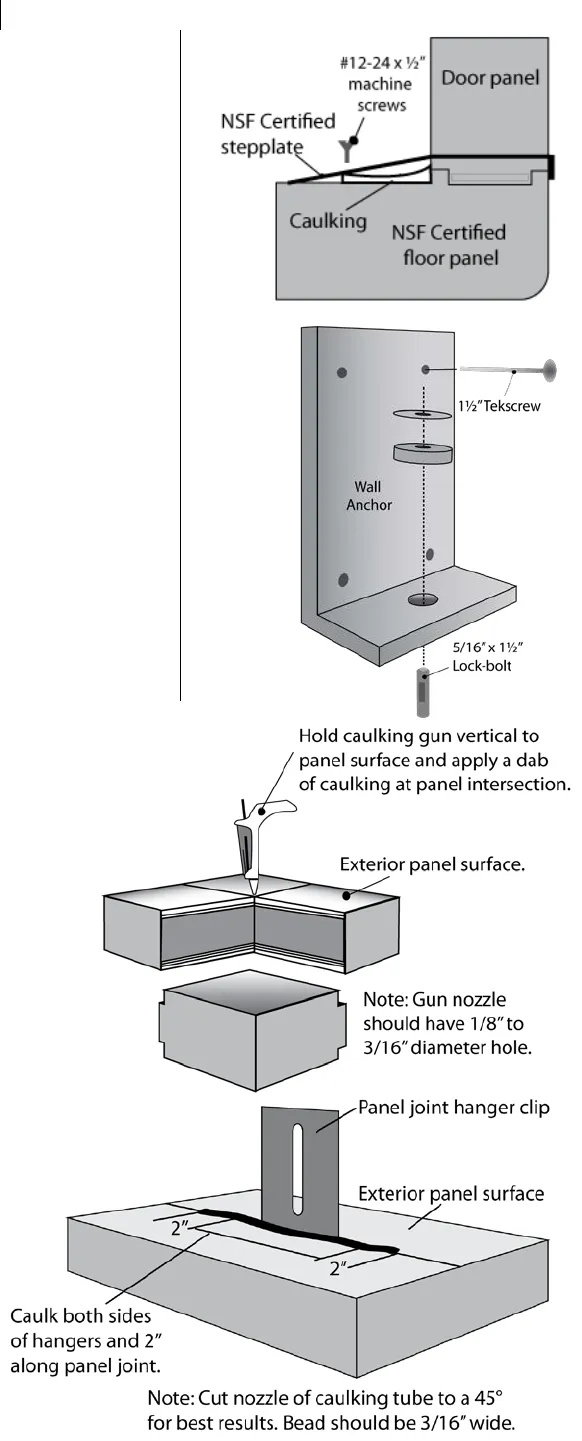

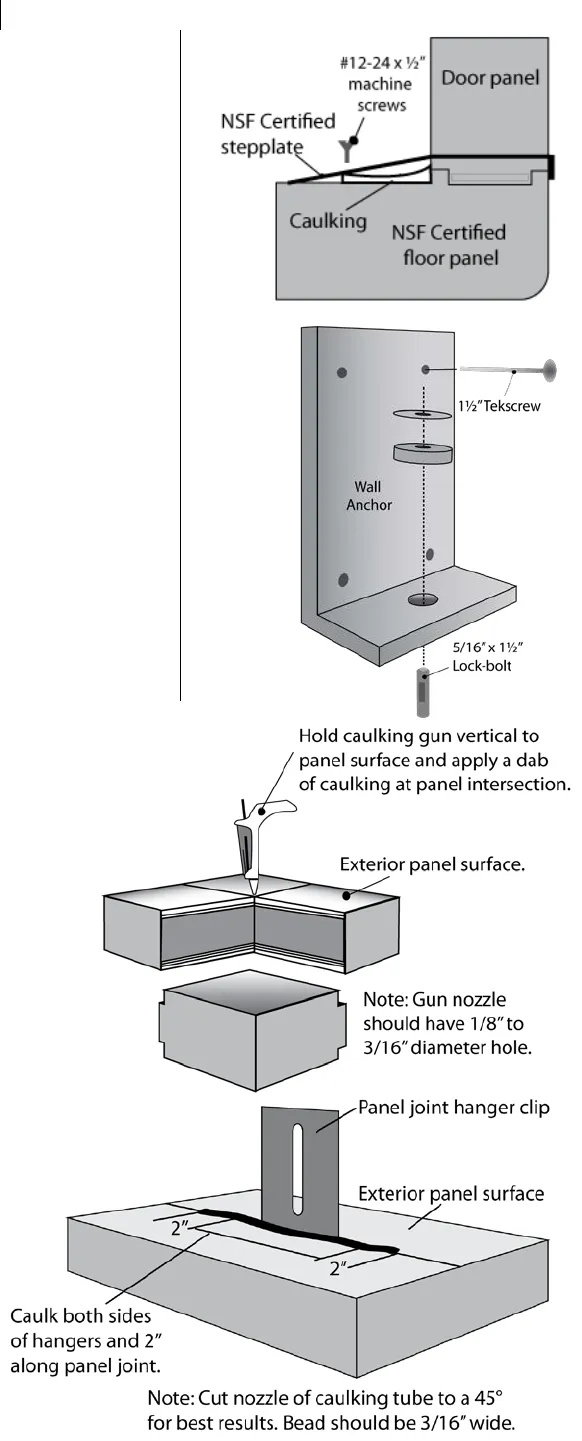

1. Preventing Vapor Leaks

A. Modular panels are square and dimensionally accurate so in

most installations they will seal effectively against vapor leaks.

However in some unusual cooler applications, minor vapor

leaks may occur. The leaks can occur if the panels follow slab

variations or if the building in which the Walk-In is installed

settles. If the internal temperature is cycled periodically, the

expansion and contraction of building materials will cause

enough movement to allow some vapor penetration.

B. Unfortunately, internal dripping does not always occur

directly across from the vapor leak which can make locating a

leak troublesome. In order to avoid time-consuming search

procedures, caulk the exterior junction of three or more panel

joints. Most leaks caused by settlement will be at these

points. See Figure 13.

C. All wall penetrations should be sealed. This includes any

protruding clips or hangers installed in panels joints. See

Figure 14.

D. Use either industrial-grade or silicone calking. When silicone

is used, sealed areas must be cut opened whenever the

panels are to be disassembled for relocation or enlargement.