32

AVANTI Service Lift for Wind Turbines

2. Install the rest of the ladder sections from top to

bottom (see Fig. 2).

3. Install the rest platforms approximately every 9 m

(see Fig. 3 and installation drawing).

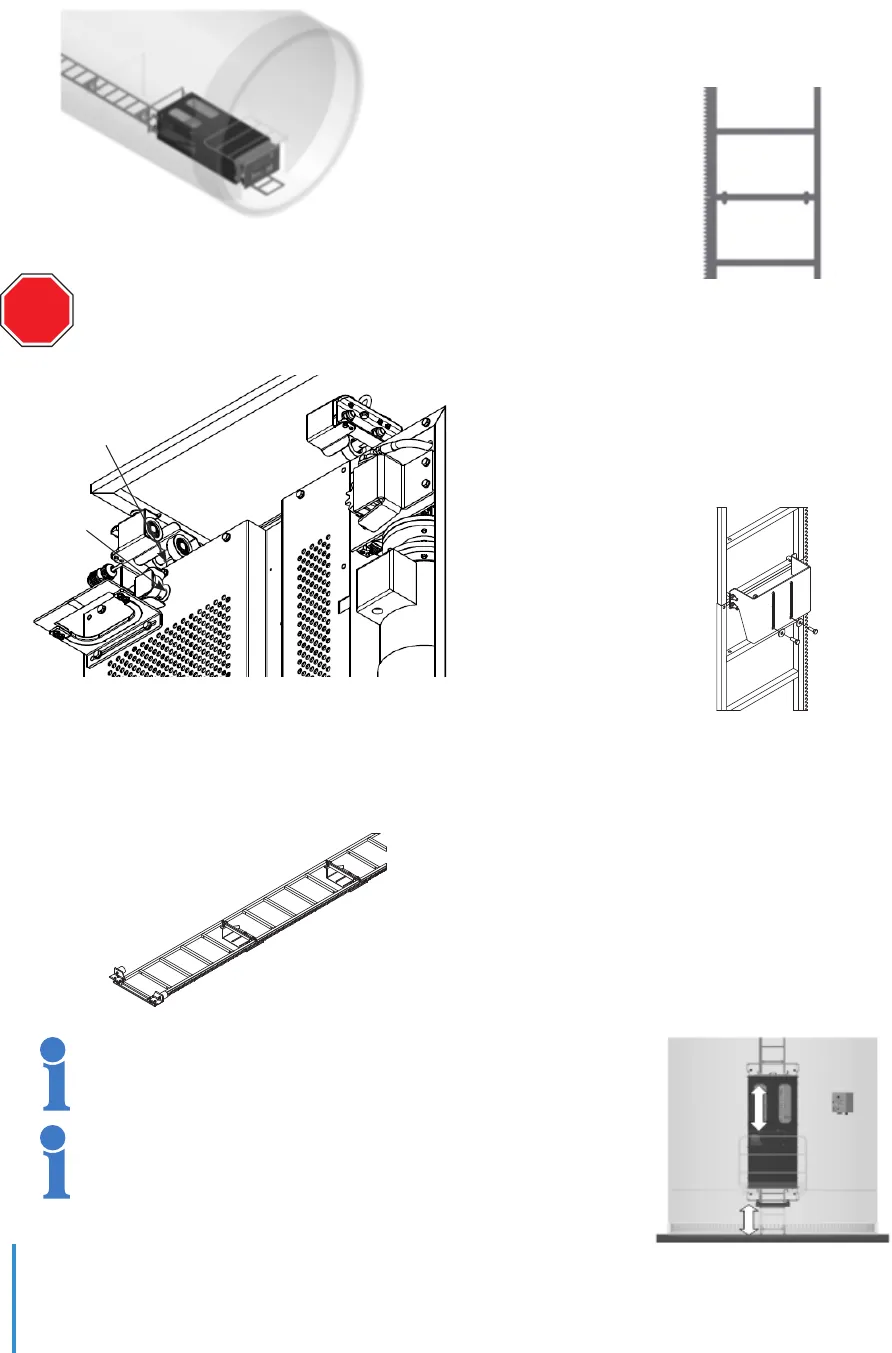

4. Position the cabin inside the bottom tower section

ensuring that bottom guiding rollers are aligned with a

ladder support (see Fig. 6).

5. Install the bottom mechanical stop and the bottom

safety position plate (see Fig. 8 and installation

drawing).

9.4 Assembly on site

After the tower sections are erected:

1. Climb up to the second tower flange.

2. While descending to the previous tower flange,

loosen connection bolts between the ladder rack

anchorages from the tower support brackets.

3. Lower down the loose ladder section until it

contacts the previous ladder section, so that no gap

exists.

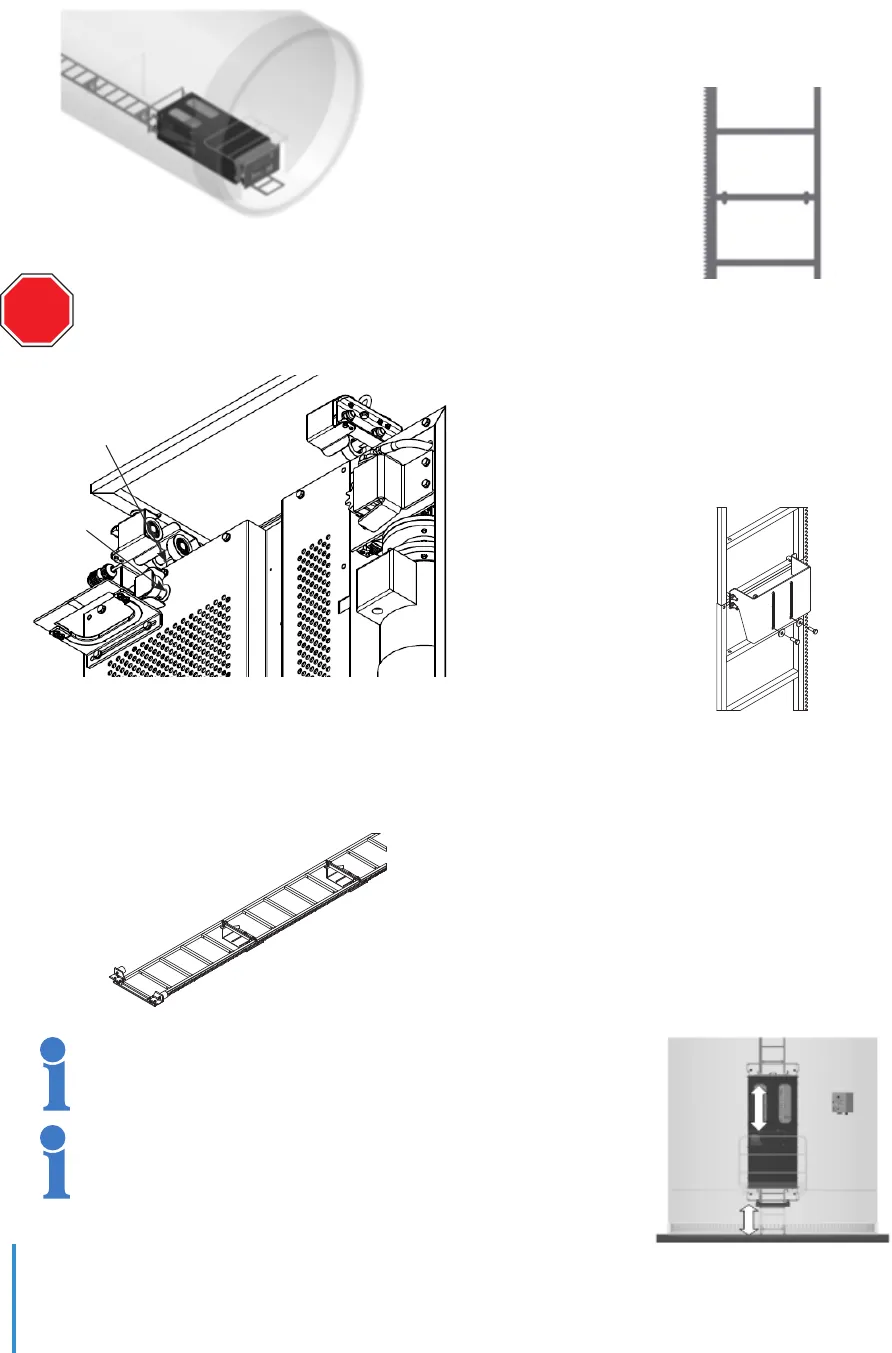

4. Tighten the connection bolts between the ladder

sections (see Fig. 9).

5. Using two calibrated rods of Ø 12 mm check that

distance between ladder sections dents is 49.7 ± 0.5

mm.

6. While climbing up, tighten the M12 connection

bolts between the ladder rack anchorages and tower

support brackets with a torque of 12 N·m (see Fig.10).

7. Climb up to next tower flange and repeat actions 2

to 5 until there are no gaps between the ladder

sections.

8. Check that gap between anti-derailment bracket

and ladder stile is 4 mm.

9. With the service lift on bottom platform, adjust the

bottom mechanical stop so that it is possible to open

the double door just above the fence railing. The

service lift must stop before the cabin main structure

hits the bottom mechanical stop (see Fig. 11).

Fig. 6

Fig. 9

Fig. 10

Fig. 11

Fig. 8

Fig. 7

It is also possible to install the cabin and

bottom mechanical stop on site.

Mount the guiding rollers shafts into the

correct holes: green shafts into green

labelled holes and orange shafts into orange

labelled holes.

Service lift can be used during installation.

GREEN LABEL

AND SHAFT

ORANGE

LABEL

AND

SHAFT

STOP