MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 4

4

EVERY 250 HOURS OR EVERY 6 MONTHS

BEARINGS AND BELTS (COVRAD

RADIATOR)

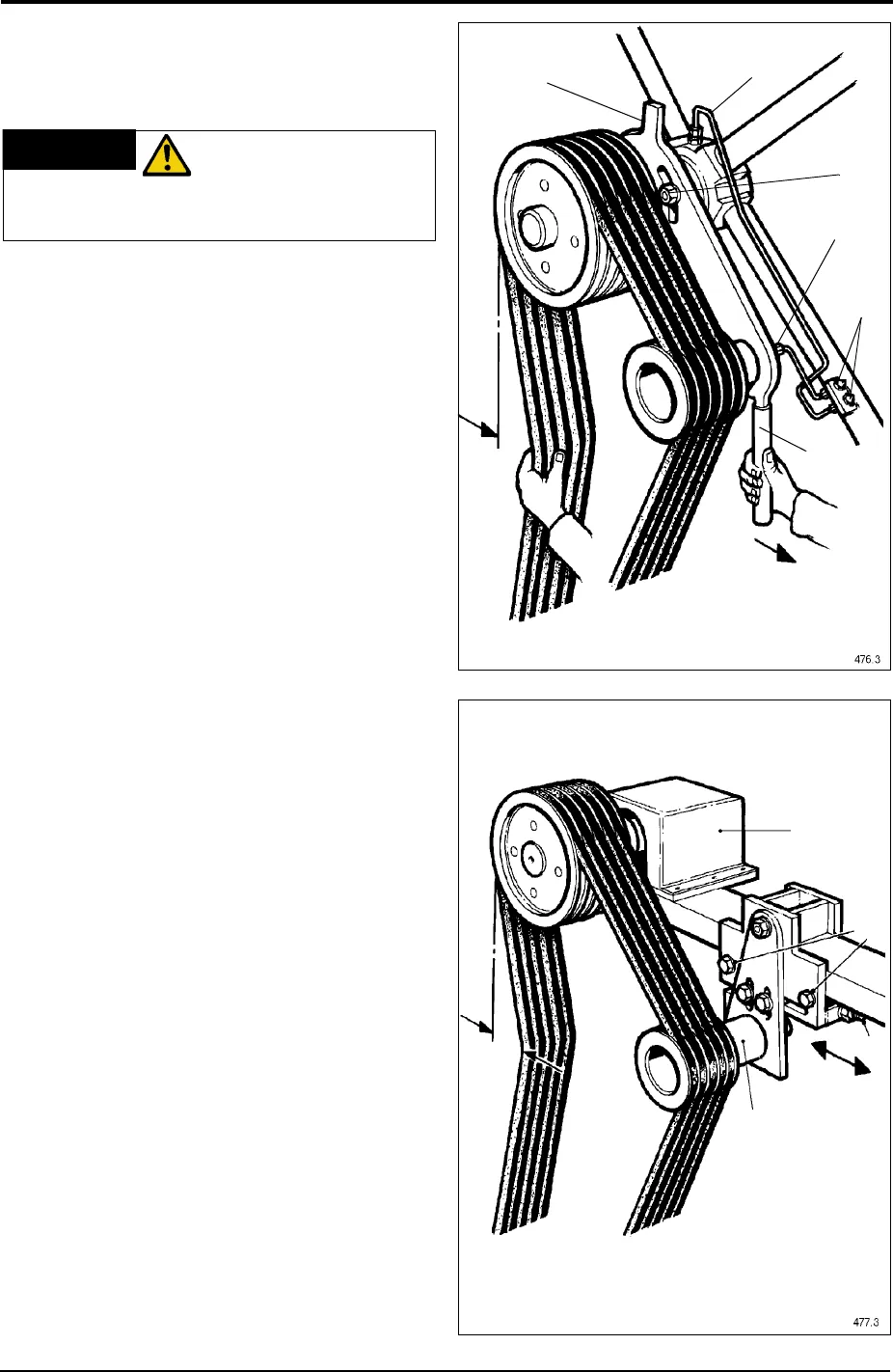

Remove the mesh guard around the fan

belts, grease the fan bearings (2) and jockey

pulley bearings (4) Fig. 32, using high

melting point lithium LM grease at greasing

points (5).

Check the tension and wear of the fan belts.

Using moderate thumb pressure midway

between the crankshaft and fan pulley, a

total deflection of 12.5 mm (1/2") is

satisfactory.

If the fan belts are worn, the complete set

should be replaced and the fan pulley to

crankshaft pulley alignment checked.

If adjustment is found necessary, slacken

the two adjusting screws (3) and using a tube

extension (6) fitted over either the fan or

jockey pulley adjusting tag (1), move

outwards to tension the belts and inwards to

slacken the belts. Having set the tension of

the belts, tighten the adjusting screws (3)

and refit the fan belt guard.

FAN BEARINGS AND BELTS

(BEARWARD RADIATOR)

Remove the mesh guard around the fan

belts. The fan bearings (1) and jockey pulley

bearings (2) do not need greasing as these

are of the pre-packed type.

Check the tension and wear of the fan belts.

Using moderate thumb pressure midway

between the crankshaft and fan pulley (1), a

total deflection of 12.5 mm (1/2") is

satisfactory (see Fig. 33). If one or more fan

belts are faulty, a complete set must

always be fitted, and the fan pulley to

crankshaft pulley alignment checked. If

adjustment is found necessary slacken the

locking bolts (3) and adjust nut (4) either way

retighten locking bolts (3) and adjusting nut

(4).

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING THE

ENGINE.

Fig. 32

1

2

3

4

5

6

Fig. 33

1

2

3

4