MAINTENANCE SCHEDULE & CHECKLISTS

42 4

012/16 Diesel, February 1997

EVERY 250 HOURS OR 6 MONTHS

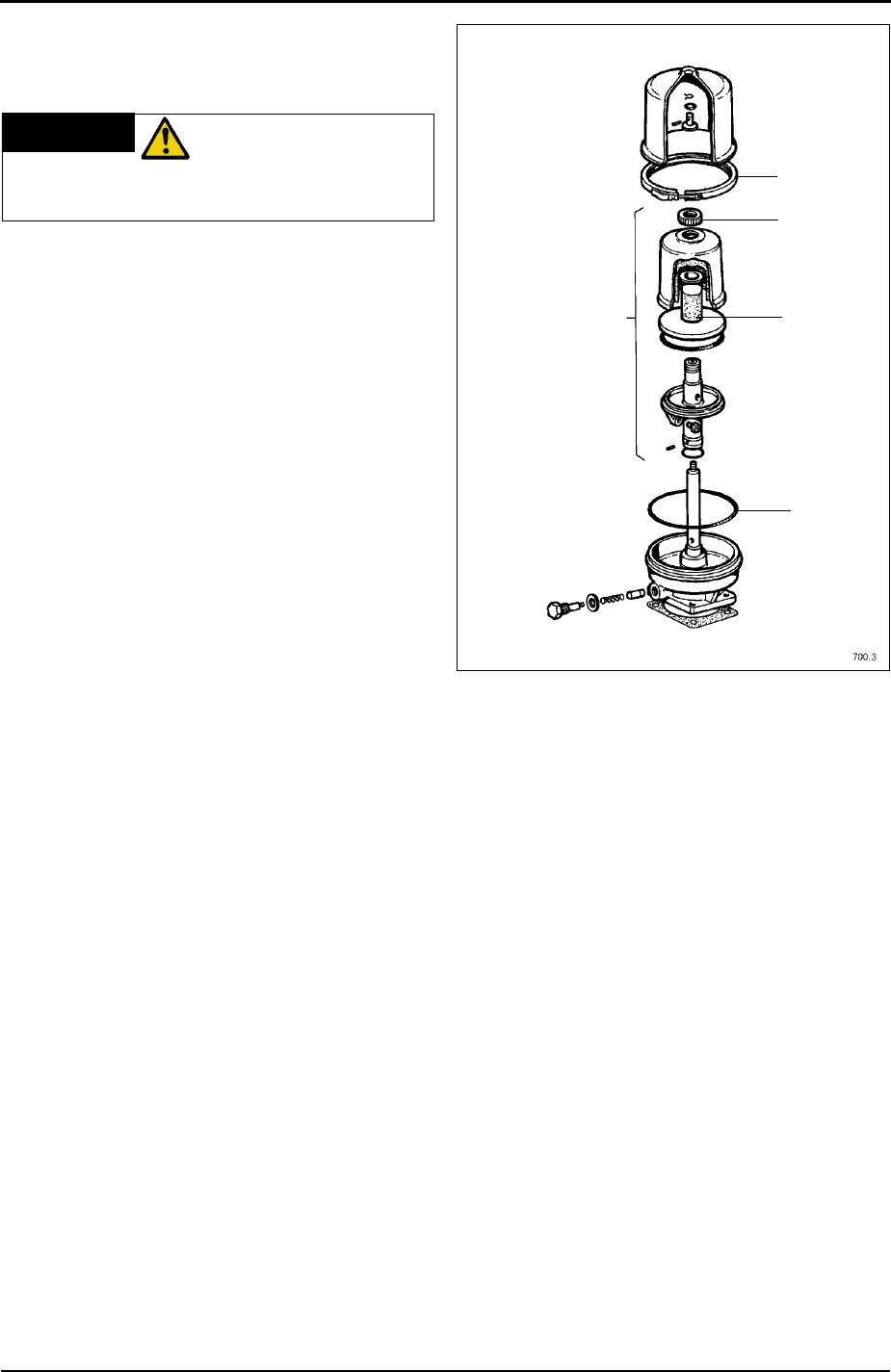

CENTRIFUGAL OIL FILTER (IF FITTED)

Stop the engine, and allow time for the oil to

drain back to the sump. Refer to Fig. 30.

1 Slacken safety clamp (1) unscrew cover

nut and lift off cover.

2 Lift off rotor assembly (2) having

allowed oil to drain from nozzles. The

rotor should be removed and replaced

on the spindle with extreme care in

order to ensure that bearings are not

damaged.

3 Secure rotor in dismantling tool T6253/

292. Unscrew rotor cover nut (3) and

separate rotor cover from body.

4 Remove standtube (4) using extraction

tool T6253/293 and clean.

5 Remove sludge from inside the rotor by

means of a spatula and wipe clean.

Ensure that all rotor components are

thoroughly cleaned and free from

deposits of dirt before reassembling the

rotor. Failure to do so could cause an

out-of-balance condition which will

accelerate bearing spindle wear.

6 Clean nozzle with brass wire. Examine

'O'-ring (5) and renew if damaged.

7 Reassemble rotor completely and

tighten top nut.

IMPORTANT: Ensure that rotor cover

and rotor body are always matched by

balance reference number and pin

location.

DO NOT INTERCHANGE ROTOR

COVERS.

8 Examine spindle journals, if damaged or

worn replace with body assembly

complete.

9 Reassemble filter completely, checking

that rotor revolves freely, then replace

filter body cover. Tighten cover nut and

secure safety clamp. The clamp ring

should be securely fitted at all times and

the filter should not be run without the

clamp ring fitted.

10 With engine running check all joints for

leakage. Check for excessive vibration.

See page 19 for oil change periods.

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING.

ALWAYS WEAR PROTECTIVE GLOVES.

Fig. 30

2

1

3

4

5