MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 3

9

Towards the rear of this section are two

check sheets, one for continuous duty sets

and one for standby duty sets, which are to

be used as a guide for operators and

maintenance personnel. The following

schedule details some of the maintenance to

be carried out as in the maintenance check

lists. However, not all are detailed. In these

cases please refer to the Workshop

M

anual

. The Schedule within this section

will be perfectly suitable for an engine

working under average conditions. If your

engine is working under particularly arduous,

dirty or dusty conditions, it will be necessary

to undertake more frequent servicing,

particularly in respect of the lubricating oil,

fuel systems and air cleaners. Correct and

regular maintenance will help prolong the life

of your engine.

The periods referred to throughout this

maintenance section are true engine running

hours as indicated on the hour recorder fitted

in the instrument panel.

DAILY INSPECTION

LUBRICATING OIL LEVEL

With the engine stopped for at least 5

minutes withdraw the dipstick, wipe clean

and re-insert into the sump. After waiting 5 -

10 seconds for the oil level to stabilise,

withdraw and check the oil level in relation to

the two marks on the dipstick. If the level is

below the top mark, remove the oil filler cap

and add the correct grade of oil to bring the

level up to the top mark. Always replace the

filler cap immediately replenishment is

completed.

COOLANT LEVEL

With the engine stopped, remove radiator

cap; the coolant should be 25 mm (1") below

the top of the filler neck. If the level is low top

up with a solution of water and inhibitor or

water and anti-freeze similar to that already

in the engine. Refer to page 21.

L

EAKS

Visually check the engine for fuel, oil, coolant

and exhaust leaks, repairing where

necessary.

AIR FILTER MAINTENANCE

(See Section A4 Maintenance Manual)

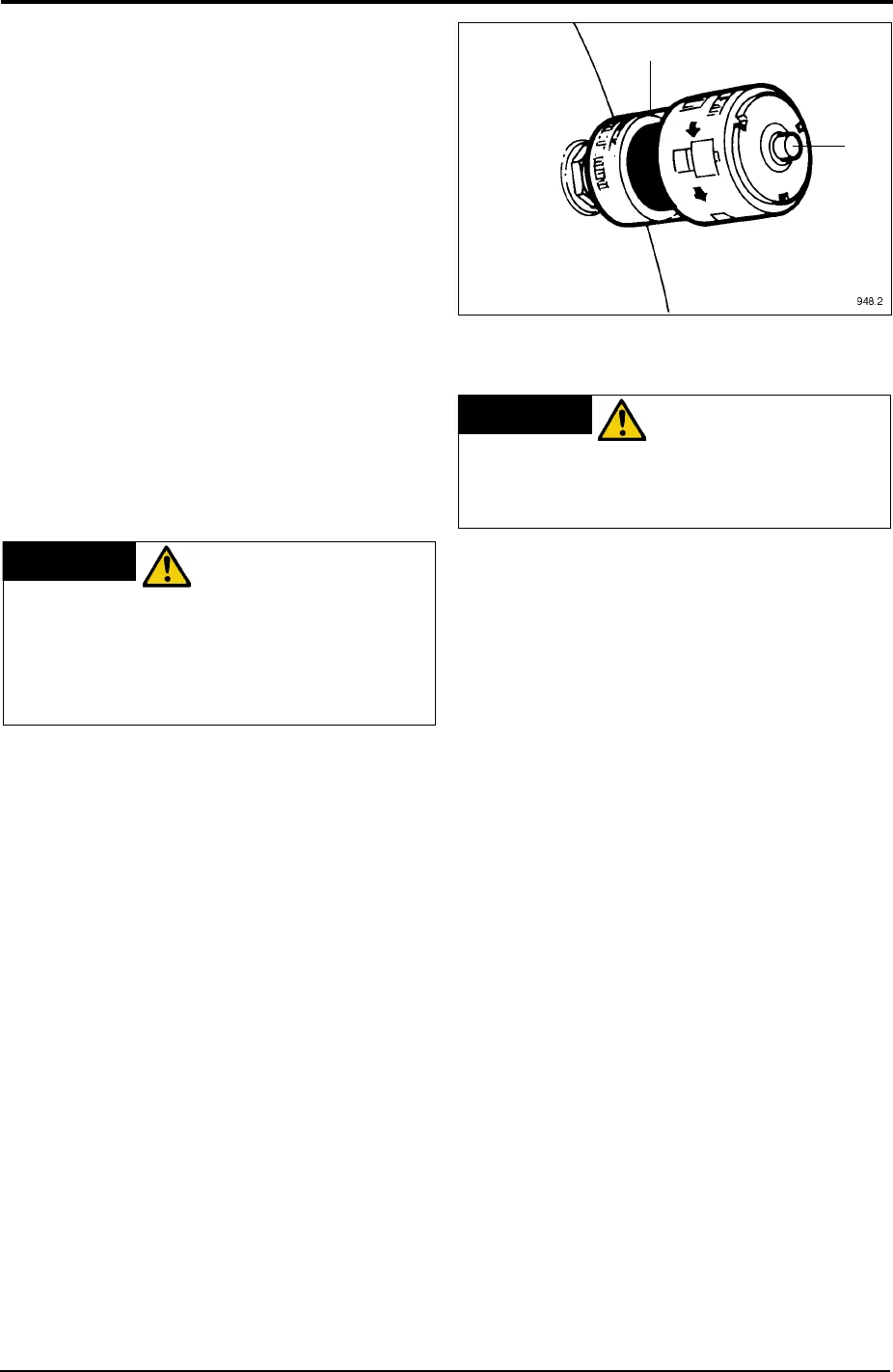

The middle section of the restriction indicator

'A' will remain clear while the air cleaner is in

a serviceable condition. When the filter

reaches its contamination limit the restriction

indicator will sense the change in manifold

pressure and middle section 'A' will change

to red. At this point the air filter must be

changed. When the air filters have been

changed reset the indicator by pressing

button 'B'. (See Fig. 26.1). Check this signal

daily.

WARNING

MAKE QUITE

CERTAIN THE

ENGINE CANNOT BE STARTED

BEFORE UNDERTAKING ANY

MAINTENANCE, PARTICULARLY IN THE

CASE OF AUTOMATICALLY STARTING

GENERATING SETS.

Fig. 26.1

A

B

WARNING

THE COOLING

SYSTEM IS

PRESSURISED - DO NOT REMOVE THE

FILLER CAP WHEN THE ENGINE IS HOT.

HAND PROTECTION MUST BE WORN.