041-135-B1-001 Rev. A 2

Run Time Table

Load Run Time (Hours)

25% 23.4

100% 5.9

Table 1, Load to approximate run time.

2.0 Service Schedule

MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD

Note: Perform at every indicated

month or operating hour interval,

whichevercomesrst. Each use

First month or 4–6

hrs.

Every 3 months or

50 hrs.

Every 6 months or

100 hrs.

Every year or

300 hrs.

Engine Oil Check Level O

Change O O

Air Cleaner Check O

Clean O

2

Replace O

1

Spark Plug Check-adjust O

Replace O

Spark Arrester Clean O

Valve Clearance Check-adjust O

3

Fueltankandlter Clean O

3

Fuel Line Check Every 2 years (Replace if necessary)

2

(1)–Replacethepaperairlterelementonly.

(2)–Service more frequently when used in dusty areas.

(3)–These items should be serviced by an authorized AlphaGen dealer.

Table 2, Generator Component Service Schedule.

For commercial use, log hours of operation to determine proper maintenance intervals. Failure to follow this

maintenance schedule could result in non-warrantable damage.

NOTE:

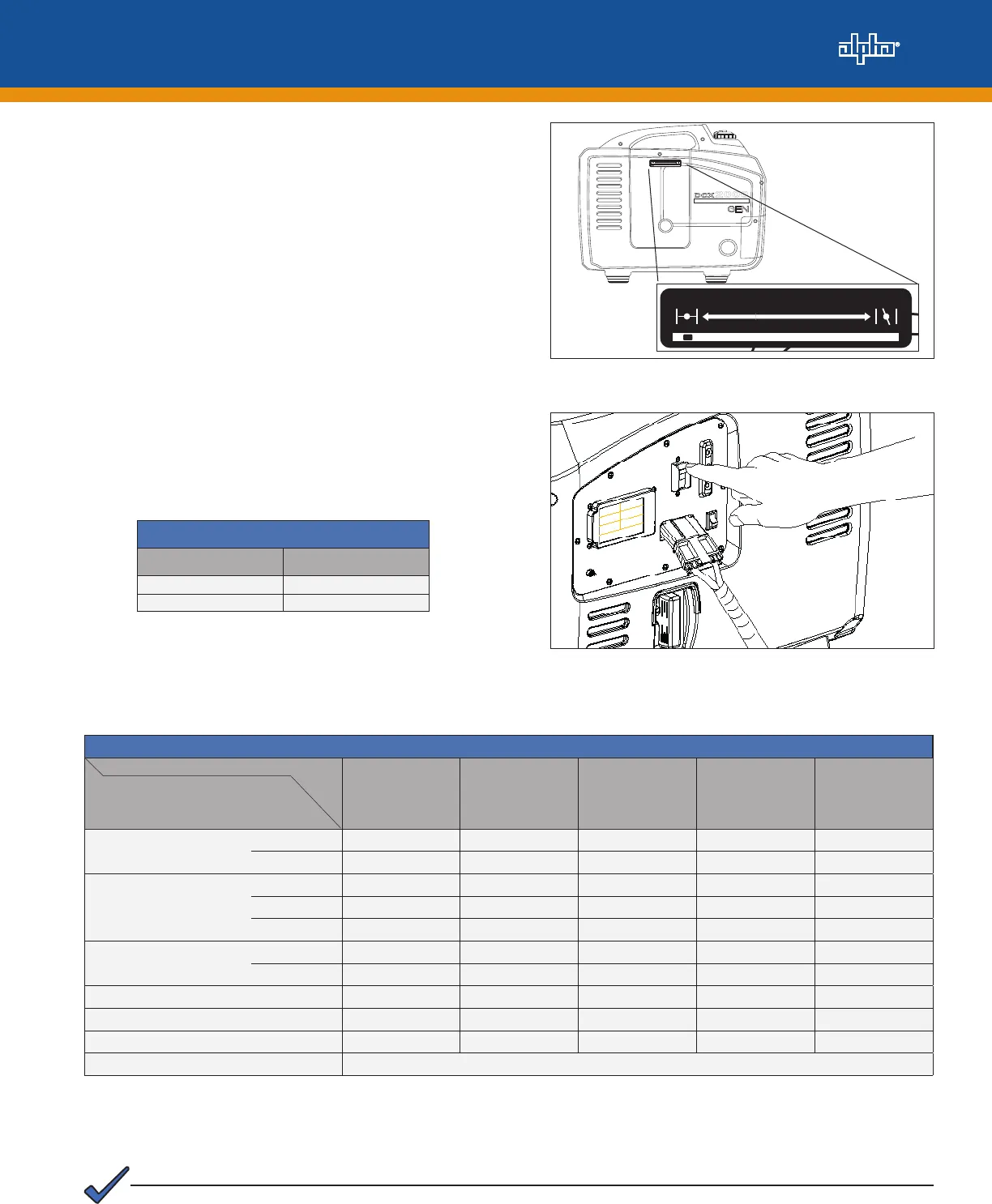

5. Move the choke lever to the START

position (Figure 4).

6. Pull the starter grip lightly until

resistance is felt, then pull briskly out

until engine starts.

7. Move the choke lever to the RUN

position after the engine warms up.

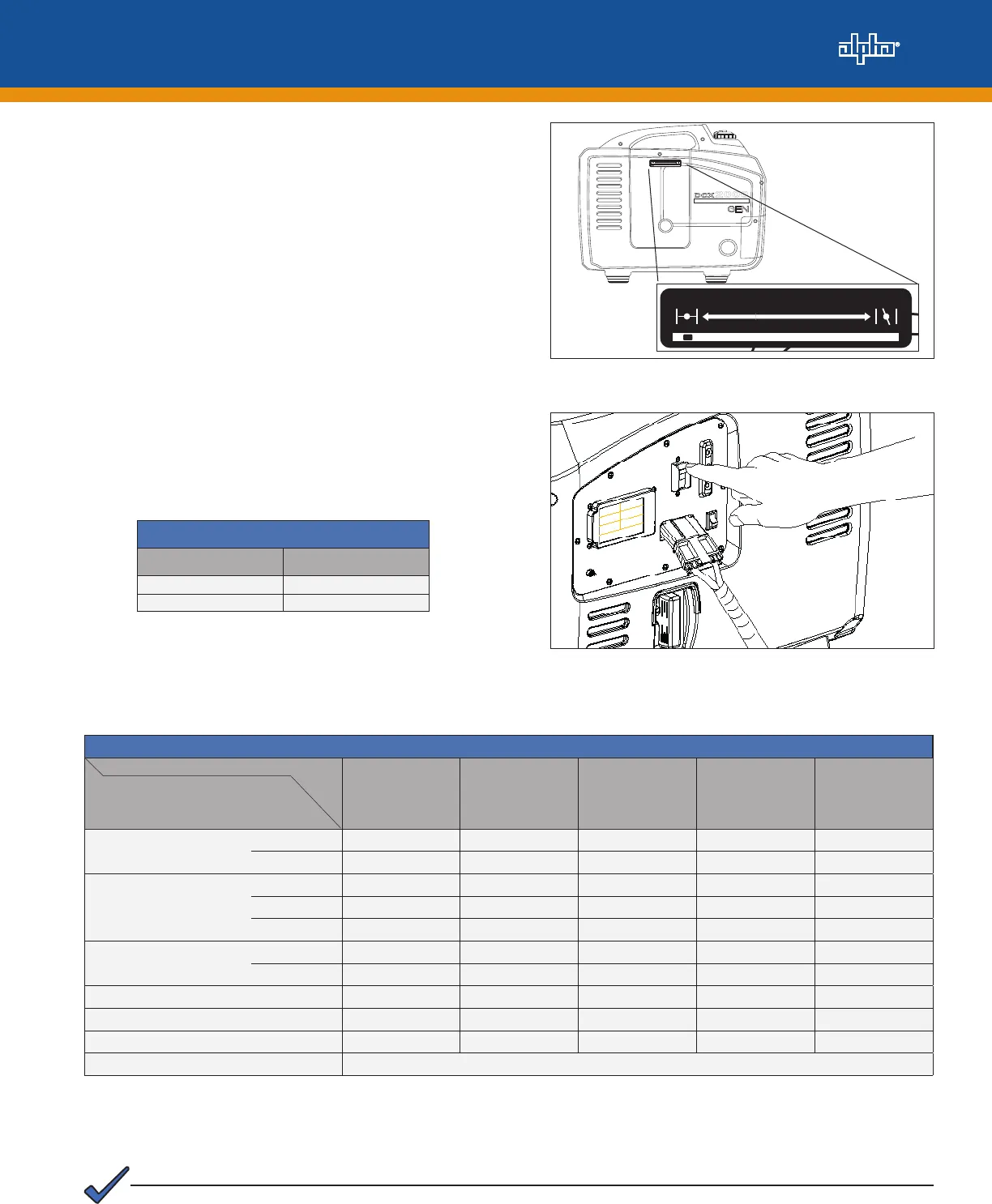

8. Turn the output breaker to the ON

position, then verify output voltage on the

LCD display.

Figure 4, Choke Lever Location and Position Indicator

DCX

2000

36V DC GENERATOR

ALPHA

START RUN

DCX

2000

36V DC GENERATOR

ALPHA

START RUN

Figure 5, Turning Output Breaker On