www.paxdiagnostics.com

FRAX-101

Power transformers are specified to withstand

mechanical forces from both transportation and in-service

events, such as faults and lightning. However, mechanical

forces may exceed specified limits during severe incidents

or when the insulation’s mechanical strength has

weakened due to aging. FRAX is a powerful tool when

trying to detect these problems.

Method basics

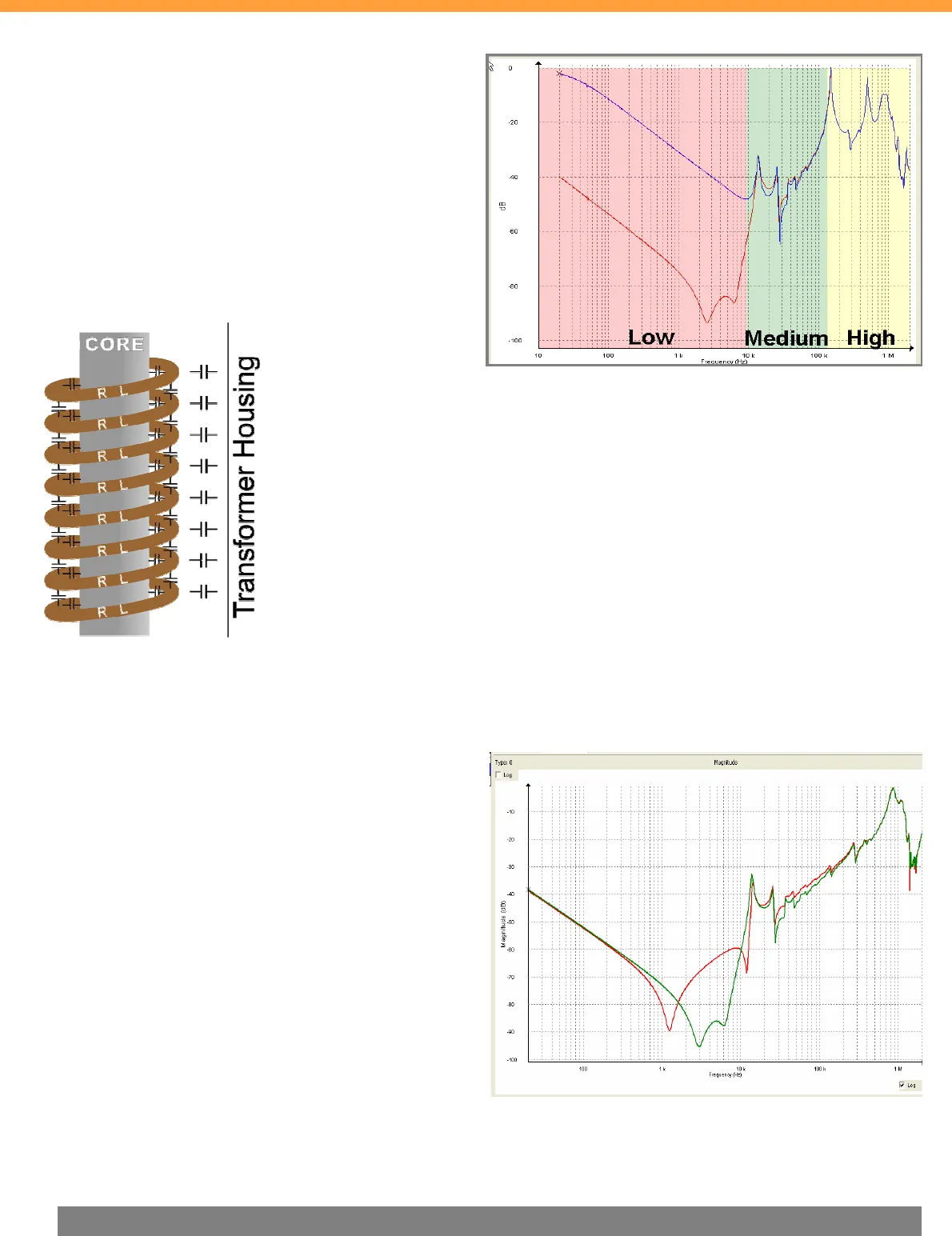

A transformer consists of multiple capacitances,

inductances and resistors, a very complex circuit that

generates a unique fingerprint or signature when test

signals are injected at discrete frequencies and responses

are plotted as a curve.

Capacitance is affected by

the distance between

conductors. Movements in the

winding will consequently

affect capacitances and

change the shape of the

curve.

The SFRA method is based

on comparisons between

measured curves where

variations are detected.

One SFRA test consists of

multiple sweeps and reveals if

the transformer’s mechanical

or electrical integrity has been

jeopardized.

Practical application

In its standard application, a

“finger print” reference curve for each winding is captured

when the transformer is new or when it is in a known good

condition. These curves can later be used as reference

during maintenance tests or when there is reason to

suspect a problem.

The most reliable method is the time based comparison

where curves are compared over time on measurements

from the same transformer. Another method utilizes type

based comparisons between “sister transformers” with the

same design. Lastly, a construction based comparison can

under certain conditions be used when comparing

measurements between windings in the same transformer.

These comparative tests can be performed 1) before and

after transportation, 2) after severe through faults 3) before

and after overhaul and 4) as diagnostic test if you suspect

potential problems. One SFRA test can detect winding

problems that requires multiple tests with different kinds of

test equipment or problems that cannot be detected with

other techniques at all. The SFRA test presents a quick

and cost effective way to assess if damages have occurred

or if the transformer can safely be energized again. If there

is a problem, the test result provides valuable information

that can be used as decision support when determining

further action.

A reference measurement on a mission critical transformer

is therefore a valuable investment as it will make analysis

easier and more reliable when an incident occurs.

Analysis guideline

As a general guideline, shorted turns, magnetization and

other problems related to the core alters the shape of the

curve in the lowest frequencies. Medium frequencies

represent axial or radial movements in the windings and

high frequencies indicate problems involving the cables

from the windings, to bushings and tap changers.

The comparisons are simplified using the built-in

analysis tools, e.g. interpretation according to Chinese

standard DL/T 911-2004, that help identify differences

between the curves.

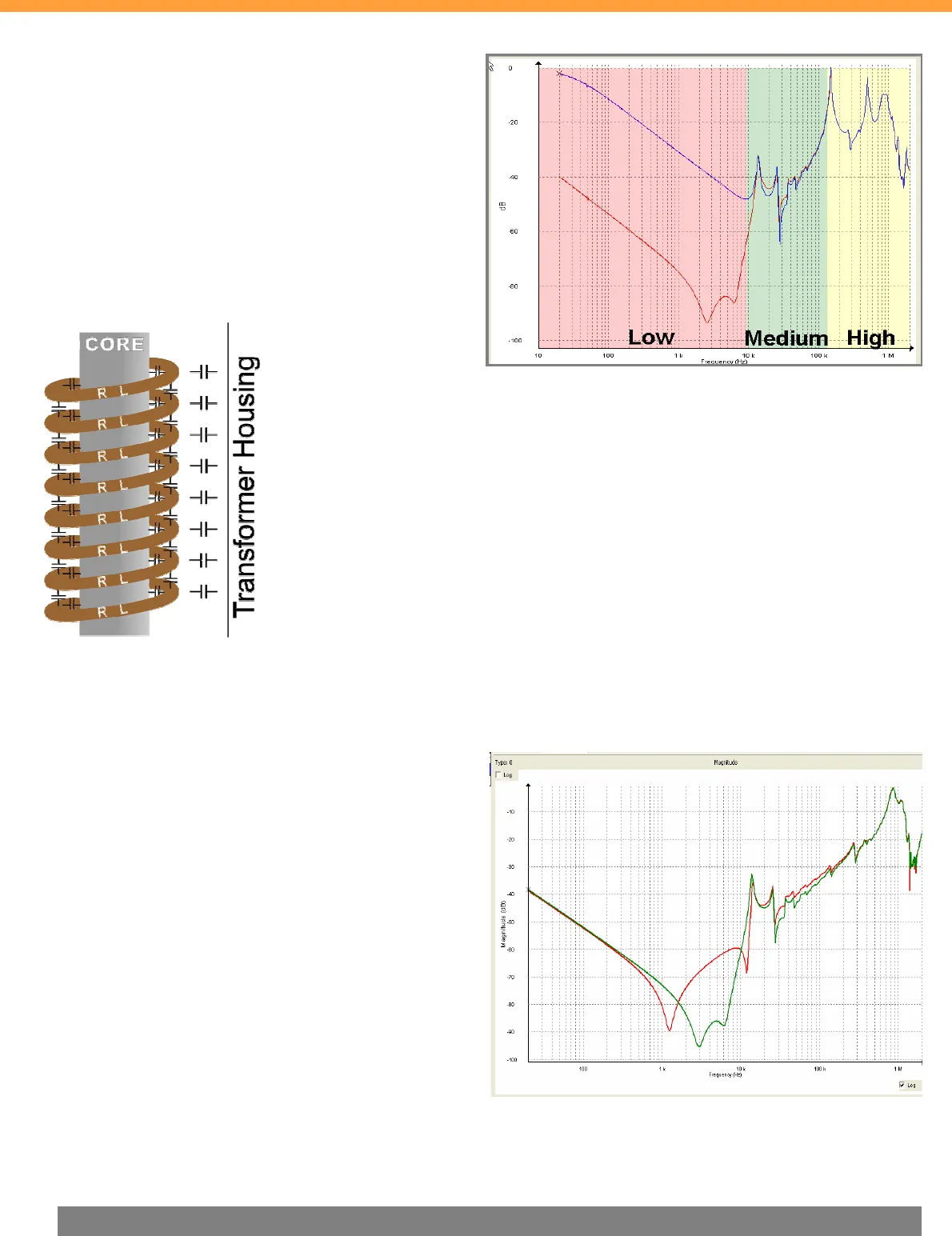

Example

The figure below shows a single phase transformer after

a service overhaul where, by mistake, the core ground

never got connected (red), and after the core ground was

properly connected (green).

This potential problem clearly showed up at frequencies

between 1 kHz and 10 kHz and a noticeable change is

also visible in the 10 kHz - 200 kHz range.

The Application