www.xerox.com/iccprofiles.com

31

3.3 Surface Cleaning and Preparation

It is the responsibility of the applicator to ensure all substrates are suitable and appropriately prepared to avoid

problems with a decal either not adhering or adhering too firmly such that removal damages the substrate. The

substrate surface must be completely clean, smooth, and dry. There must be no dirt, oil, grease or solvent

residue remaining.

Prior to cleaning with solvents, test the cleaning solvent on an inconspicuous area of the application surface to

check for potential damage. Always test adhesion and paint/adhesive compatibility prior to installation.

The following cleaning and surface preparation conditions must be followed immediately prior to application.

Failure to adhere to these requirements can cause adhesion loss and therefore reduce the durability and

performance level of the decal.

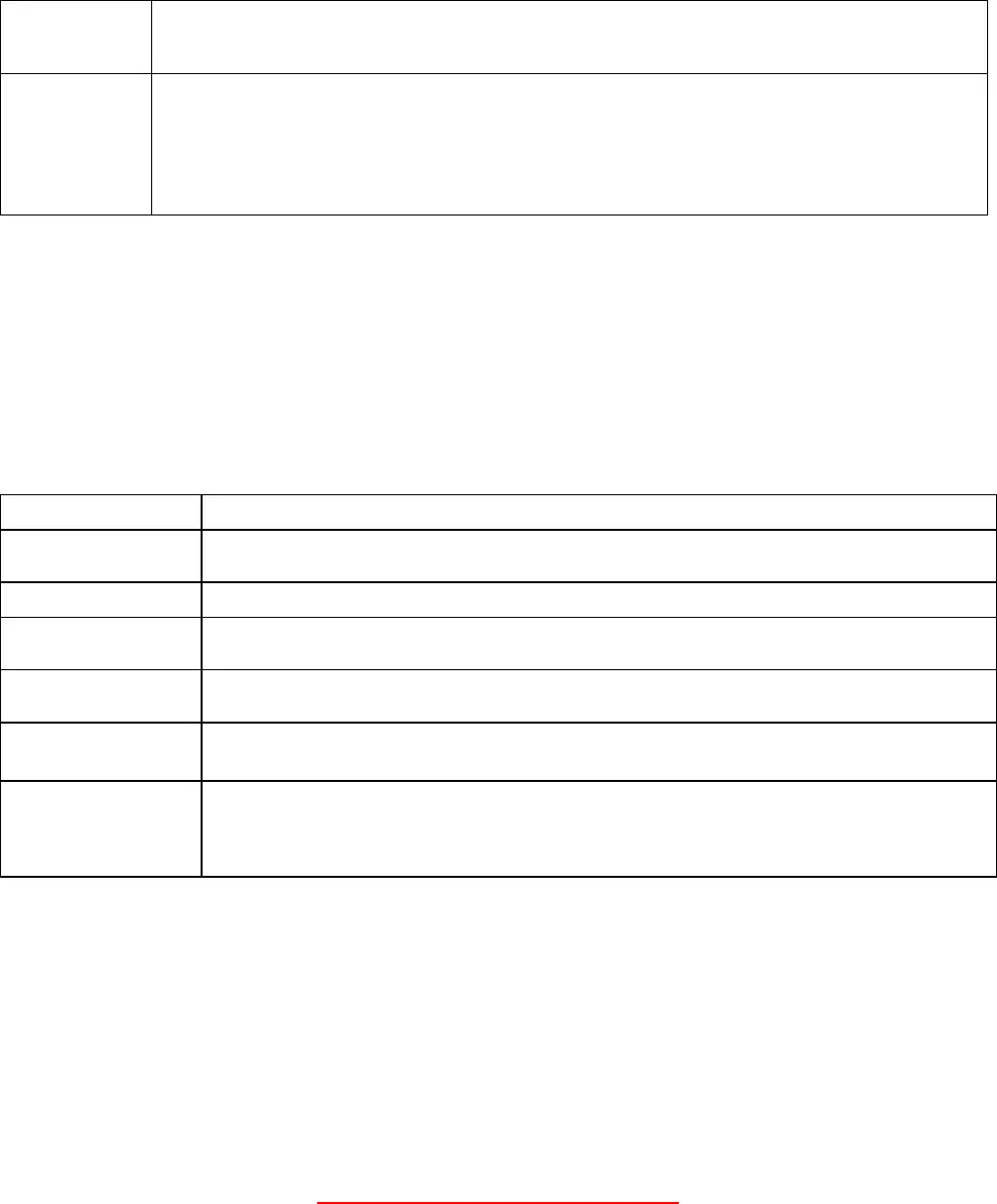

Pre-Cleaning

• Remove all dirt and grime with soapy water. If grease, oil, wax, etc. are present, the

substrate must be scrubbed with a solvent wipe (Xylene, heptane, ethylacetate,

denatured alcohol).

Final

Preparation

• After proper cleaning, the substrate surface should be thoroughly wiped by using a

clean rag saturated with a cleaner such as DuPont’s Pre-Sol Brand Solvent 3919S,

Rapid Prep by Rapid Tack, or Sherwin Williams R7K-156.

• Other solvents such as IPA (isopropyl alcohol), VM&P Naptha, Xylol, or lacquer thinner

may also be used instead of DuPont 3919S. However, care should be taken to assure

that the final dry wiping is accomplished prior to the solvent evaporating.

3.2 Painted Surfaces

Avoid highly pigmented or dull metallic paints (which tend to chalk and flake), latex paints, paints containing

migratory agents such as chlorinated waxes and silicone, oil alkyd primers and enamels. If applying film to a

newly painted surface, follow all drying and curing instructions. All air-drying paints should be allowed to dwell

at or near room temperature and humidity conditions for one week prior to vinyl application. Chalked and

otherwise weathered paint surfaces must be refurbished or refinished.

High quality exterior grade paints are recommended as a good base for self adhesive vinyl.

3.3 Other Surfaces

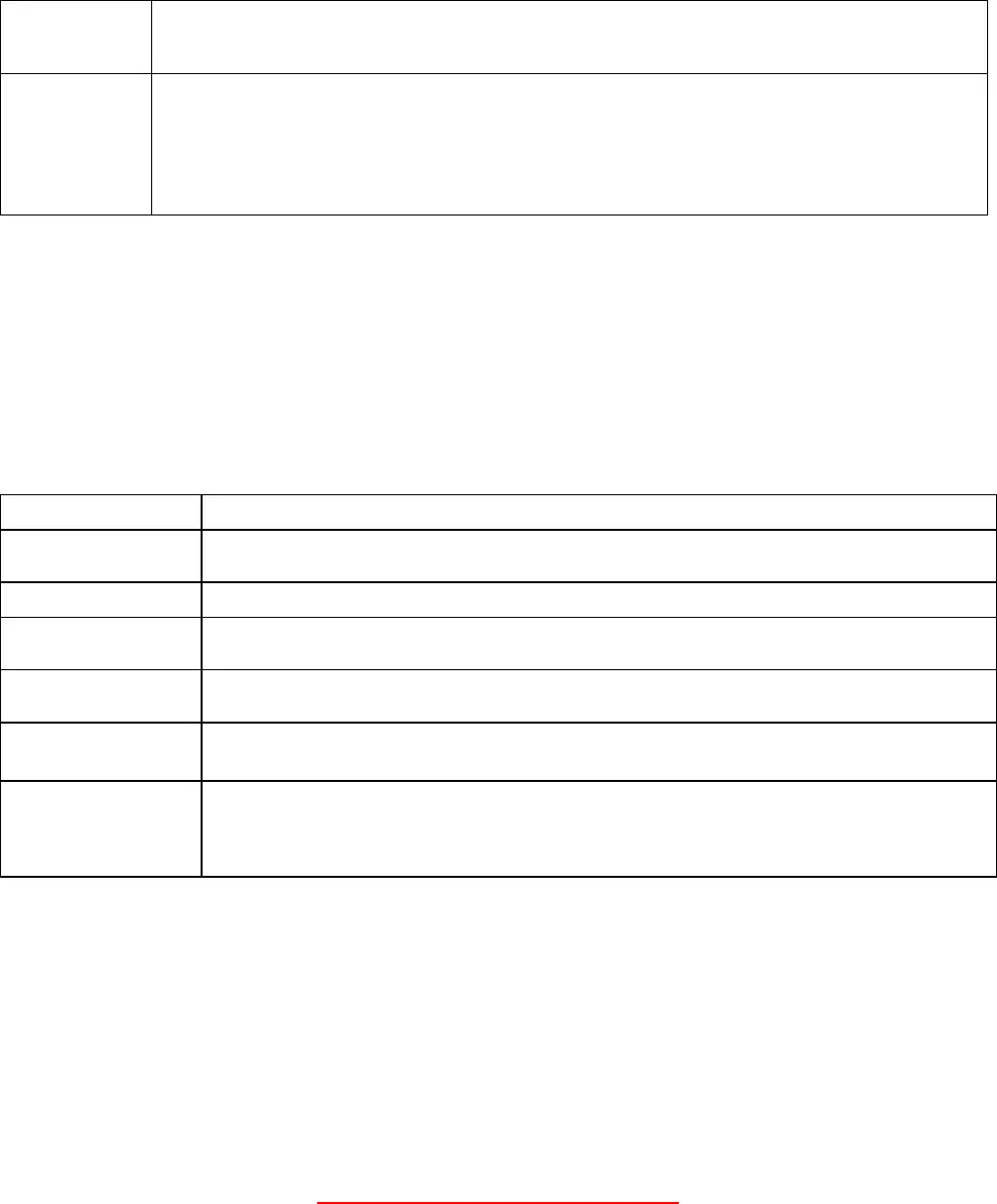

Tin

Including Alloys of Tin, Copper, Magnesium, Lead: Not recommended.

Stainless Steel

Stainless steel tends to maintain cold surface temperatures longer then most

substrates. Use a heater immediately before and after application to accelerate bond.

MDF / Wood

Generally not recommended.

Aluminum,

ABS, Acrylics

Use high quality exterior grade paints.

Galvanised Steel

Ensure the substrate is properly galvanized, it is recommended to test all galvanized

steel substrates and prepare thoroughly before application.

Poly-carbonate

Fibreglass

With a soft cloth wipe the surface with isopropyl alcohol. Inadequate preparation may

result in air bubbles. Test for out-gassing

Glass

Glass must be perfectly clean. Remove anything attached to the surface using a

scraper . Spray the glass with cleaning solution and dry using a soft rubber

squeegee. Wetting the glass with cleaning solution (DuPont Prepsol or Isopropyl

Alcohol) will reduce the chance of scratching the surface during the scraping process.

3.4 Installation

Before starting installation, consult the appropriate product data sheet for information regarding application

temperature range and recommended substrates. These factors are critical to a successful application and

future decal performance. If the substrate surface temperature is below minimum requirements, the substrate

must be heated to application temperature to accelerate the ultimate adhesion of the vinyl.

Mark the decal location on the application surface. For multi panel decals the overlap should be 6-12mm.

Generally do not use application fluid or the "wet method" for installation as this can reduce ultimate adhesion

or cause fogging with clear vinyls.

The decal must be squeegee-ed before and after pre-mask removal. During pre-mask removal, decals are

exposed to potential edge lifting. In order to eliminate this, re-squeegee the decal (especially the edges).