250g/m

2

Banner Fabric – Fire Retardant 16

Description

Tear resistant polyester fabric designed for fine image quality in either 360 or 720 dpi print mode, for

use indoors or outdoors against a flat surface without lamination. This fabric has a fire retardant

coating and is certified M2 flame retardant for use in fire sensitive indoor spaces. A functional fabric

that can be "finished" to become a vast array of graphics.

Applications

Ideal for indoor and outdoor banner applications, e.g., art galleries, retail and event promotions, long

hallways, showrooms, supermarkets, ceiling displays, museums, theatre lobbies, entranceways,

petrol stations, car park advertising, backdrops, signage, and tradeshows.

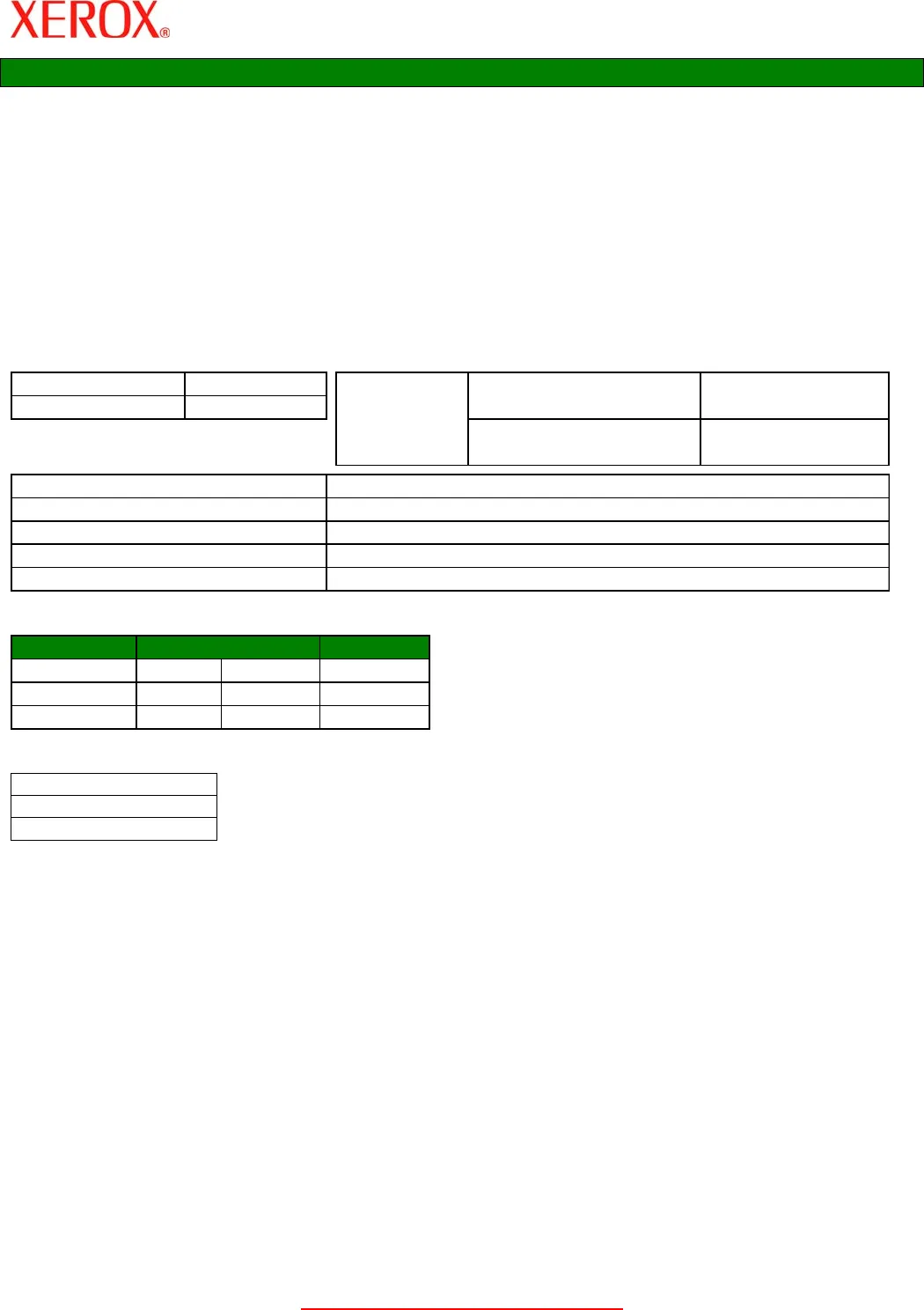

Physical Characteristics

Base Weight

250

m

2

Total Calliper

260 microns

Indoor Unlaminated

Outdoor Unlaminated

<0.5%

Temperature stability

Dimensional stability

-10deg C to +60 deg C

Fire Rating NF P 92-503 - Class M2, DIN-4102 - Class B1

Durability

Tensile strength

Tearing resistance

>1000 N/5cm warp, >800 N/5cm weft

>70 N warp, >70N weft

2 years

1 year

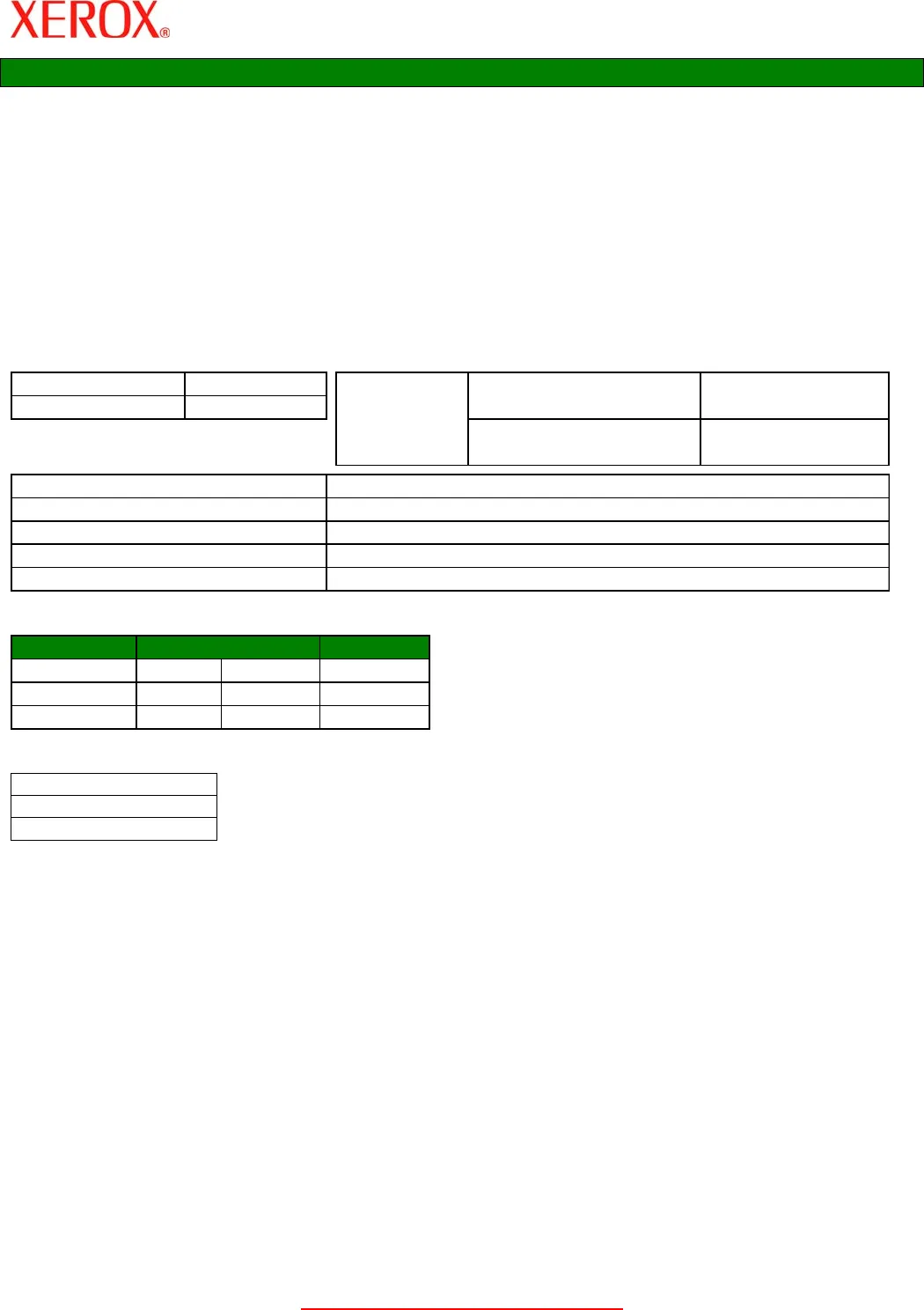

Dimensions

Code Length

023R02002 54” 1372mm 25m

023R02004 42" 1067mm 25m

023R02005 36” 914mm 25m

Width

Compatibility

Xerox X2

Xerox Xpress

Seiko IP4XXX

Operating Instructions

• Store in a cool, dry environment, free from direct sunlight, within temperatures of 10-35

o

C and

non-condensing relative humidity of 30-70%. Store the product in its original carton and

wrapper to protect from dust and moisture. Shelf life is 2 years if kept in original packaging.

• Ensure that roll ends are protected and that the edges of the media are not damaged. If the

media edges are not flat this can result in damage to the printer.

• Keep the image surface dry and free of grease, oil, silicones and dirt.

• Use within the temperature range 18-30˚C and relative humidity of 40-60%.

• Avoid over-saturating with ink for such as CMY / CMYK black. Reduce individual and overall ink

limits (<220%) to improve drying and production speed. Too much ink may cause light "oil-

spots" to appear. Working at lower ink limits improves image weather resistance.

• Some banding may be evident close viewed but from the likely viewing distance for banner

graphics it should be invisible. Unidirectional printing can help reduce banding.

• This is a heavily coated, extremely thick material. It may be easier to run this media from the

back roller and the automatic cutter should not be used during media loading or print production.

• Do not fold images. Use "slip sheets" to prevent image offset from one print to another.

• Over-lamination is not required.

www.xerox.com/iccprofiles.com

27