Use A Non-Hardening Gasket Sealer

Sealers are NOT required on FEL-PRO PermaTorque

®

head gaskets. However, embossed

steel shim, copper-faced, or steel-faced gaskets should be coated with a non-hardening

automotive gasket sealer as a supplemental seal.

Lightly coat bolt threads and the underside of the bolt heads with EP grease or similar

lubricant. When they enter the water jackets of an engine, bolt threads should be coated with

a non-hardening automotive sealer to prevent leakage. Refer to the manufacturer’s service

manual or examine the engine to determine where the bolt holes lead.

Watch Bolt Lengths and Sizes

Head bolts on some engines may vary in length and size, and it is important that they be

replaced in their original location. Either mark the bolts by position, or place them on a

bench in the order you remove them.

Use A Torque Wrench

Uneven torque can cause block distortion and head warpage, resulting in coolant or

combustion leaks. Use a good torque wrench, properly calibrated, and follow exact

specifications for the proper torque. The basic tightening procedure is to first snug up

bolts, then tighten in stages, and then complete with the final torque specified.

Follow Torquing Sequences

Each manufacturer has an approved torquing sequence to follow for each engine, to insure

the best possible seal and eliminate chances of distortion and warpage. In general, the

sequence starts at the center and spirals out to the ends of the head.

Warm Engine and Retorque Head

Run the engine to normal operating temperature after torquing head bolts. Heat expansion

and contraction can radically change the torque readings. Retorque all head bolts to the

correct settings while the engine is still warm. If working with aluminum components, let

the engine cool completely first. Remember that FEL-PRO

®

PermaTorque

®

designs do

NOT require retorquing.

Retorque After 300 to 500 Miles

If retorque-type head gaskets are used, retorque after 300 to 500 miles.

1

2

3 4

5

6

7

8

910

11

1213

14

1

23

4 5

67

8 9

10

11

12

13

14

1

2

3

4

5

6

7

8

9

10

123 4 5

678 9 10

1

2

3

45

6

7

89

10

FRONT

FRONT

1

2

3

4

5

6

7

8 9

10

11

12

13

14

15

16

17

18

19

20

1

2

34

5

6

78

9

10

1112

13

14

1516

17

CYLINDER HEAD GASKET INSTALLATION TIPS

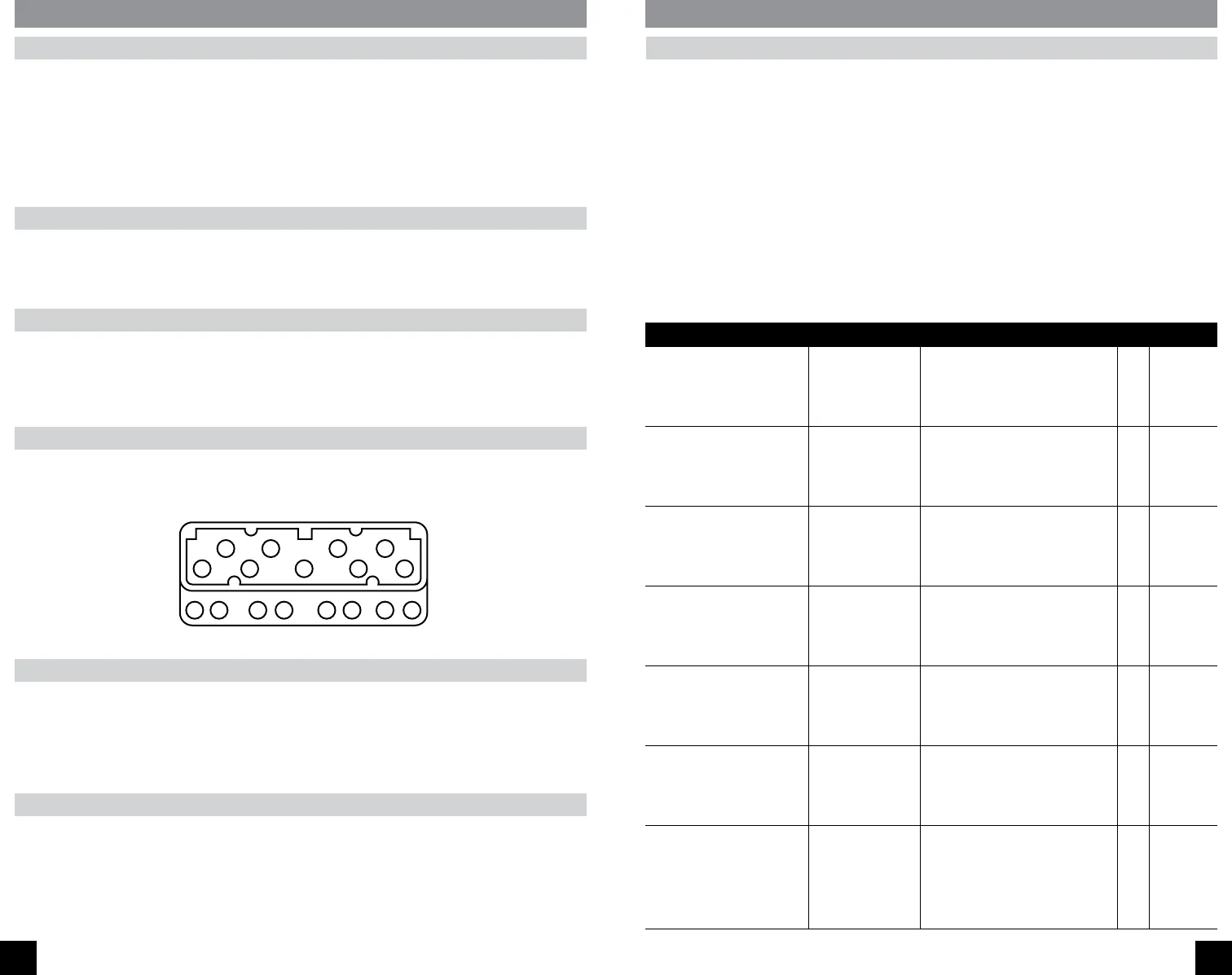

Torque-to-Yield Head Bolts

Torque-to-yield is a method used by most current engine manufacturers to tighten head

bolts. The head bolts are torqued to their yield point, which may permanently stretch the

bolts. This results in a more even clamping force over the entire area of the gasket. Bolts

should first be tightened to a specified torque (measured in foot-pounds), and then tightened

an additional partial turn (measured in degrees) to the bolt yield point. The inexpensive

FEL-PRO

®

Torque-to-Angle Indicator (part number TRQ-1) will help you accurately

measure the required partial turn in degrees.

Because the head bolts may have stretched, the engine manufacturer may recommend

against reusing them. Consult the OEM manual on head bolt reuse. Since you may not

know how many times a T-T-Y bolt has been removed and reinstalled, FEL-PRO engineers

suggest that it is always a good idea to use new bolts. FEL-PRO head bolt sets are available

for many domestic and imported engines. The Torque Tables™ indicate which engines

have bolt sets offered in the FEL-PRO product line.

FEL-PRO

®

T-T-Y HEAD BOLTS

ENGINE YEARS FT.-LBS.

TORQ.

SEQ.

HEAD BOLT SET

PART NUMBER

FORD PRODUCTS 6 & V6 (CONT.)

232 OHV (3.8L) 12 Valve Ford 2003-96 Truck

●❍

1st 15, 2nd 29, 3rd 37,

PERFORM THE NEXT THREE STEPS ON

EACH BOLT BEFORE MOVING TO NEXT

BOLT IN SEQUENCE: 1) loosen 2-3 turns,

2) Long bolts 29-37; Short bolts 15-22,

3) turn 175-185 degrees

94

ES 72156

ES 72160

232 OHV (3.8L) 12 Valve Ford 1995 Truck

●❍

1st 15, 2nd 30, 3rd 37,

PERFORM THE NEXT THREE STEPS ON

EACH BOLT BEFORE MOVING TO NEXT

BOLT IN SEQUENCE: 1) loosen 2-3 turns,

2) Long bolts 11-19; Short bolts 7-15,

3) turn 85-95 degrees

94

ES 72131

232 OHV (3.8L) 12 Valve Ford 2004-98 Car

●❍

1st 15, 2nd 30, 3rd 37,

PERFORM THE NEXT THREE STEPS ON

EACH BOLT BEFORE MOVING TO NEXT

BOLT IN SEQUENCE: 1) loosen 2-3 turns,

2) Long bolts 29-37; Short bolts 15-22,

3) turn 180 degrees

94

ES 72160

232 OHV (3.8L) 12 Valve Ford 1997-96 Car

●❍

1st 15, 2nd 30, 3rd 37,

PERFORM THE NEXT THREE STEPS ON

EACH BOLT BEFORE MOVING TO NEXT

BOLT IN SEQUENCE: 1) loosen 2-3 turns,

2) Long bolts 30-37; Short bolts 15-22,

3) turn 175-185 degrees

94

ES 72156

ES 72160

232 OHV (3.8L) 12 Valve Ford 1995-94 Car

●❍

1st 15, 2nd 30, 3rd 37,

PERFORM THE NEXT THREE STEPS ON

EACH BOLT BEFORE MOVING TO NEXT

BOLT IN SEQUENCE: 1) loosen 2-3 turns,

2) Long bolts 11-19; Short bolts 10-15,

3) turn 85-95 degrees

94

ES 72131

232 OHV (3.8L) 12 Valve Ford 1993-91 Car

●❍

1st 37, 2nd 45, 3rd 52, 4th 59,

PERFORM THE NEXT THREE STEPS ON

EACH BOLT BEFORE MOVING TO NEXT

BOLT IN SEQUENCE: 1) loosen 2-3 turns,

2) 11-18, 3) Long bolts turn 85-105 degrees

;

Short bolts turn 65-85 degrees

94

ES 72131

232 OHV (3.8L) 12 Valve Ford 1990-84 Car

●❍

Flanged Hex Head bolts: 1st 37, 2nd 45,

3rd 52, 4th 59, PERFORM THE NEXT

THREE STEPS ON EACH BOLT BEFORE

MOVING TO NEXT BOLT IN SEQUENCE:

1) loosen 2-3 turns, 2) 11-18,

3) Long bolts turn 85-105 degrees;

Short bolts turn 65-85 degrees

82

ES 72129

ES 72131