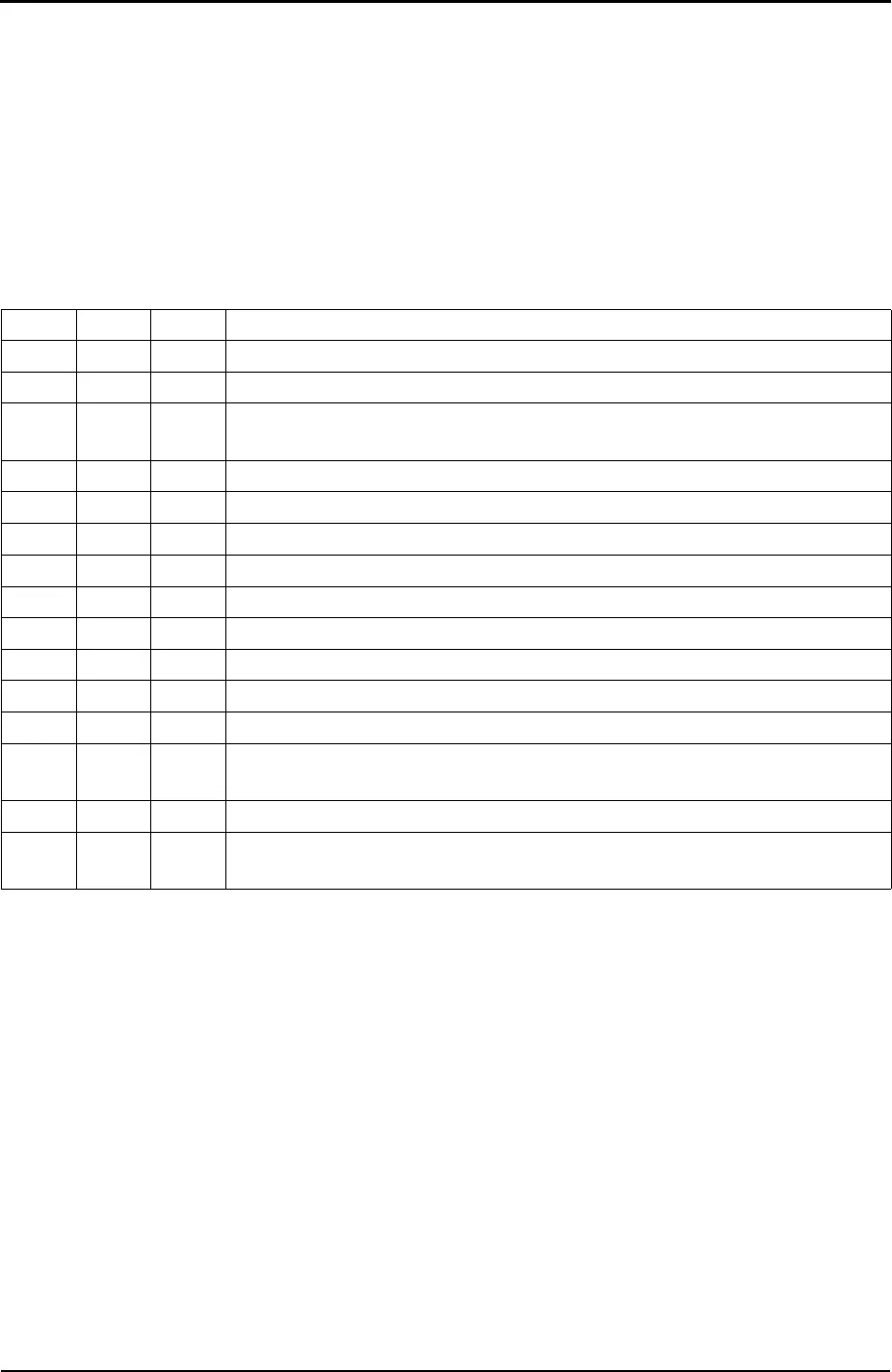

PREVENTIVE MAINTENANCE

62 4

012/16 Diesel, February 1997

SCHEDULE FOR ENGINES IN CONTINUOUS DUTY

For preventive maintenance operations must be applied at the interval (hours or months)

which occurs first.

A Daily

B Every 250 hours or 6 months

C Every 2500 hours or 12 months

* By a person who has had the correct training.

A B C Operation

● Check the coolant level

● Check the lubricating oil level

●

Check the restriction indicators for the air filters and, when

necessary, renew the filter elements

● Drain any water/sediment from the primary fuel filter

● Check the condition and the tension of all drive belts

● Check the specific gravity and the pH value of the coolant

● Renew the lubricating oil and filter

● Visually check for radiator air restriction

● Clean centrifugal oil filter

● Renew the canister of the main fuel filter

● Clean the water trap sedimenter

● Equalise bridge pieces and check valve clearances

●

Check that the air charge cooler and the radiator are clean and free

from debris

● Drain and flush the coolant system and renew coolant mixture

●

Ensure that the fuel injectors are checked and corrected or

renewed, if necessary*