OPERATING INSTRUCTIONS

4012/16 Diesel, February 1997 2

9

INITIAL STARTING OF THE ENGINE

WHEN FITTED WITH THE

REGULATEURS EUROPA 2100

HYDRAULIC GOVERNOR

NOTE: It is recommended that for initial

starting of new or overhauled engines, any

automatic starting or control systems are by-

passed and the engine is controlled

manually with the load disengaged, but with

the air shut-off valves manually set to the

'run' position (see Fig. 12).

R

emove the filler plug from the top face of

the governor and fill with oil to the line in the

sight glass (see Fig. 14). Refer to

Workshop Manual, Section AA41 for the

c

orrect grade of oil. Replace the plug.

Ensure that the fuel supply to the engine is

turned off.

Rotate the engine using the cranking device,

as described on page 55, in the correct

d

irection of rotation for two revolutions to

ensure that all working parts are free.

Disengage or remove the cranking device

immediately after use.

NOTE: When the engine is fitted with three

starter motors i.e. two electric and maybe

one air starter then on early engines one of

the starters may need to be removed to

enable the cranking device to be fitted.

The minimum and maximum speed stops

are factory set. Reduce the governor speed

setting by turning the hand wheel clockwise

until there is no further movement of the

output levers.

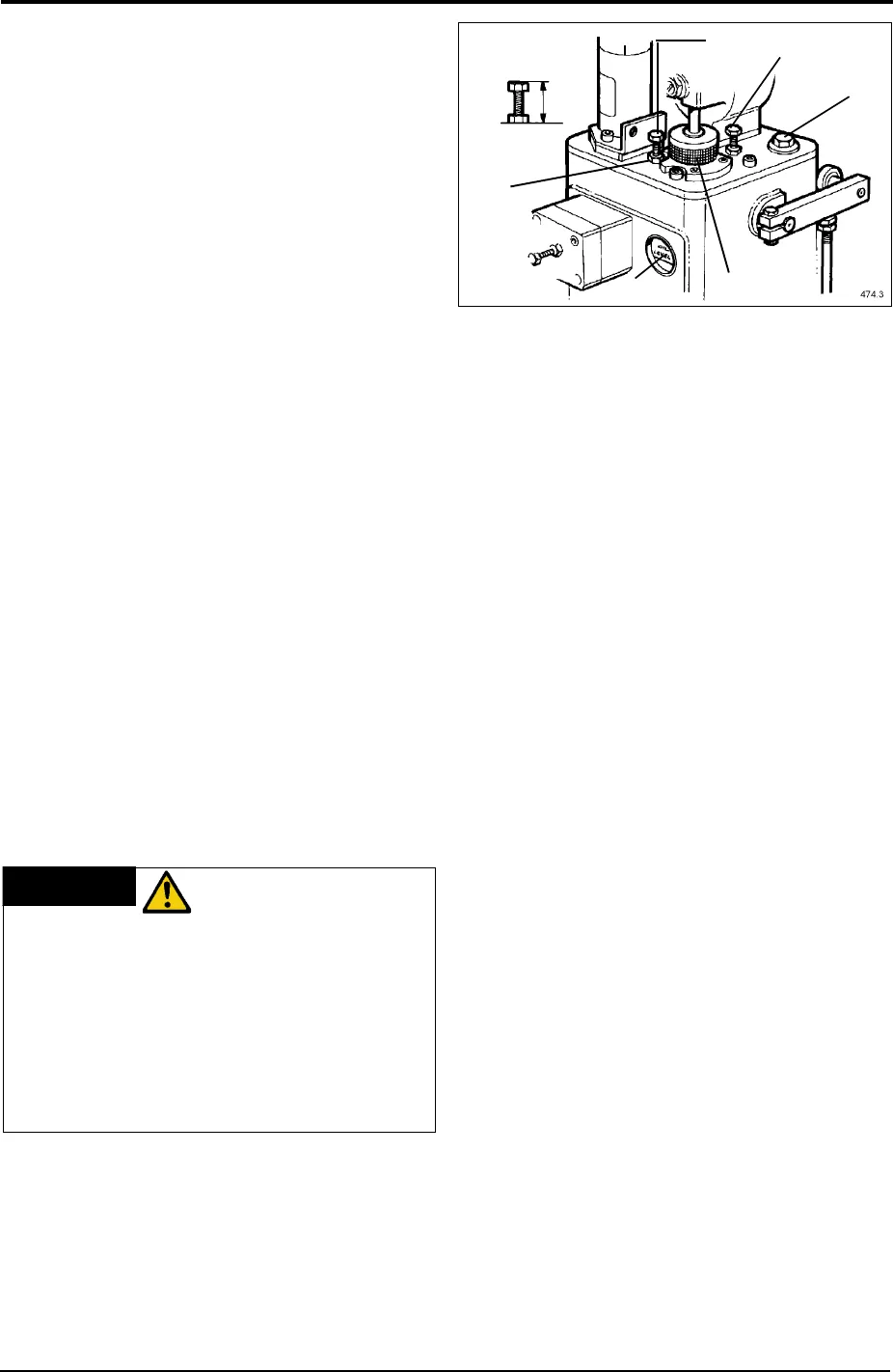

Key

(Fig. 14)

1 Locknut

2 Solenoid energised to stop

3 Minimum speed stop screw

4 Maximum speed stop screw

5 Oil filler plug

6 Hand control wheel

7 Oil level sight glass

Ensure the starting batteries are fully

charged. Energise the shutdown solenoid

('stop' position) and motor the engine over

on the starter until the oil pressure gauge

registers approximately 40 kPa (5 lb/in²).

Continue cranking for a further 10 seconds,

to ensure that the oil has reached the

turbochargers. Stop the engine by releasing

the start control and visually check the

engine for fuel or oil leaks, rectifying where

necessary. Turn on the fuel supply and bleed

the fuel system. Ensuring that the shutdown

solenoid is de-energised ('run' position)

crank the engine on the starter. The engine

should start and run up to the minimum

speed setting. Increase the engine speed by

turning the hand wheel anti-clockwise until

there is no further movement of the output

levers. With the engine running up to the

maximum speed setting, adjust the hand

wheel to obtain the desired operating speed.

Check the engine for fuel and oil leaks. Apply

load.

WARNING

UNDER NORMAL

CONDITIONS

GENERATING SETS MUST NOT BE RUN

AT LESS THAN THEIR NORMAL

OPERATING SPEED. OPERATION

BELOW THIS SPEED WILL DAMAGE

THE AUTOMATIC VOLTAGE

REGULATOR (AVR) THEREFORE

ISOLATE THE AVR BEFORE REDUCING

THE ENGINE SPEED.

Fig. 14

2

3

4

5

6

7

1