7. Valves in chilled water and condenser water

circuits open and water circulating properly. Do

not permit water warmer than 100 F to flow

thru cooler.

COMPRESSOR ROTATION — Set capacity control

(item 2, Fig. 3) to “Hold.” Press machine ON-STOP

and START buttons.

As soon as motor starts to turn, press machine

ON-STOP button. Check motor rotation thru sight

glass in motor end bell (Fig. 1). Motor rotation

must be clockwise when viewed from motor end. If

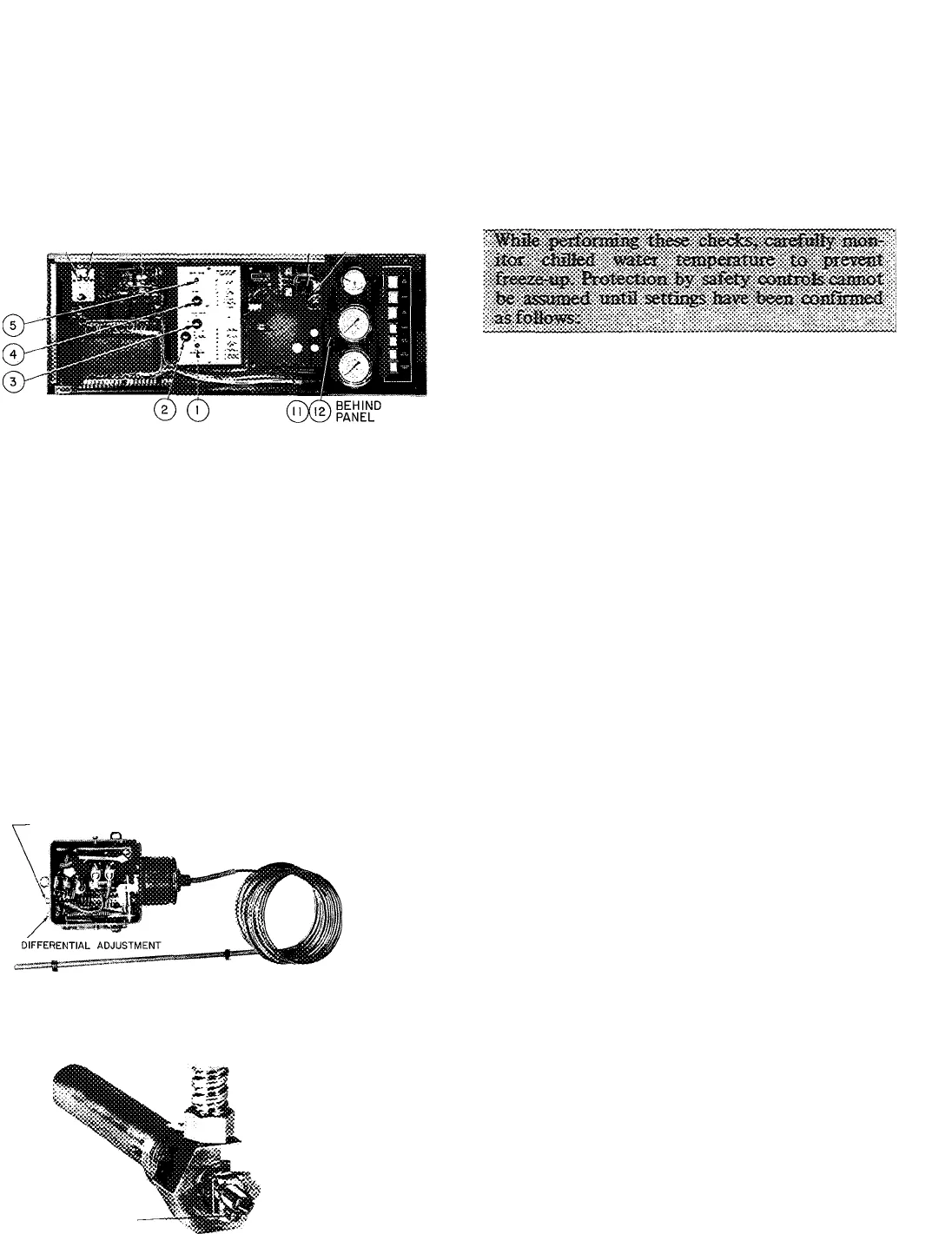

® © 0

© @

LEGEND

1. Motor Current Calibration Adjustment

2. Capacity Control Switch

3. Electrical Demand Adjustment

4. Thermostat (chilled water)

5. Throttle Range Adjustment

6. Condenser High-Pressure Cutout Switch (manual reset)

7. Cooler Low-Pressure Cutout Switch (manual reset)

8. Program Timer

9. Motor High-Temperature Cutout (manual reset)

10. Bearing High-Temperature Cutout (manual reset)

11. Low Oil Pressure Cutout

12. Economizer-Cooler Differential Pressure Switch

Fig. 3 — Control Center

not, reverse any 2 of 3 power leads coming into

motor starter and recheck rotation.

COMPRESSOR OPERATION

Press machine ON-STOP and START buttons and

let compressor come up to speed. Press machine

ON-STOP button and listen for any unusual sounds

coming from the compressor and transmission

housing as compressor coasts to a stop.

Program timer prevents rapid recycling of com

pressor and allows restart-15 minutes after stop.

Checking Safety Control Settings

add

Open main disconnect (all power off to starter

and controls). Set capacity control to “Hold.”

Place a clamp-on ammeter on one of the 3 starter

leads. Install jumper between [0] •

Close disconnect(s), start compressor and check oil

pressure and temperature (items 10 and 15, Fig. 1).

With compressor running, manually operate the

prewhirl vanes with the capacity control switch.

Do not exceed 100 percent full load amperage.

1. Set control 1 (chilled water low temperature

cutout) as indicated in Table 3.

2. Stop machine, open disconnect(s), remove

jumper and check controls 2 and 3 of Table 3.

3. Controls 4 and 5 do not require alteration of

factory settings. ;

4. Control 6 may require adjustment for operation

of unit at low design suction. Refer to Table 3.

Table 3 — Checking Safety Controls

SAFETY OR CONTROL DEVICE

RECOMMENDED SETTING

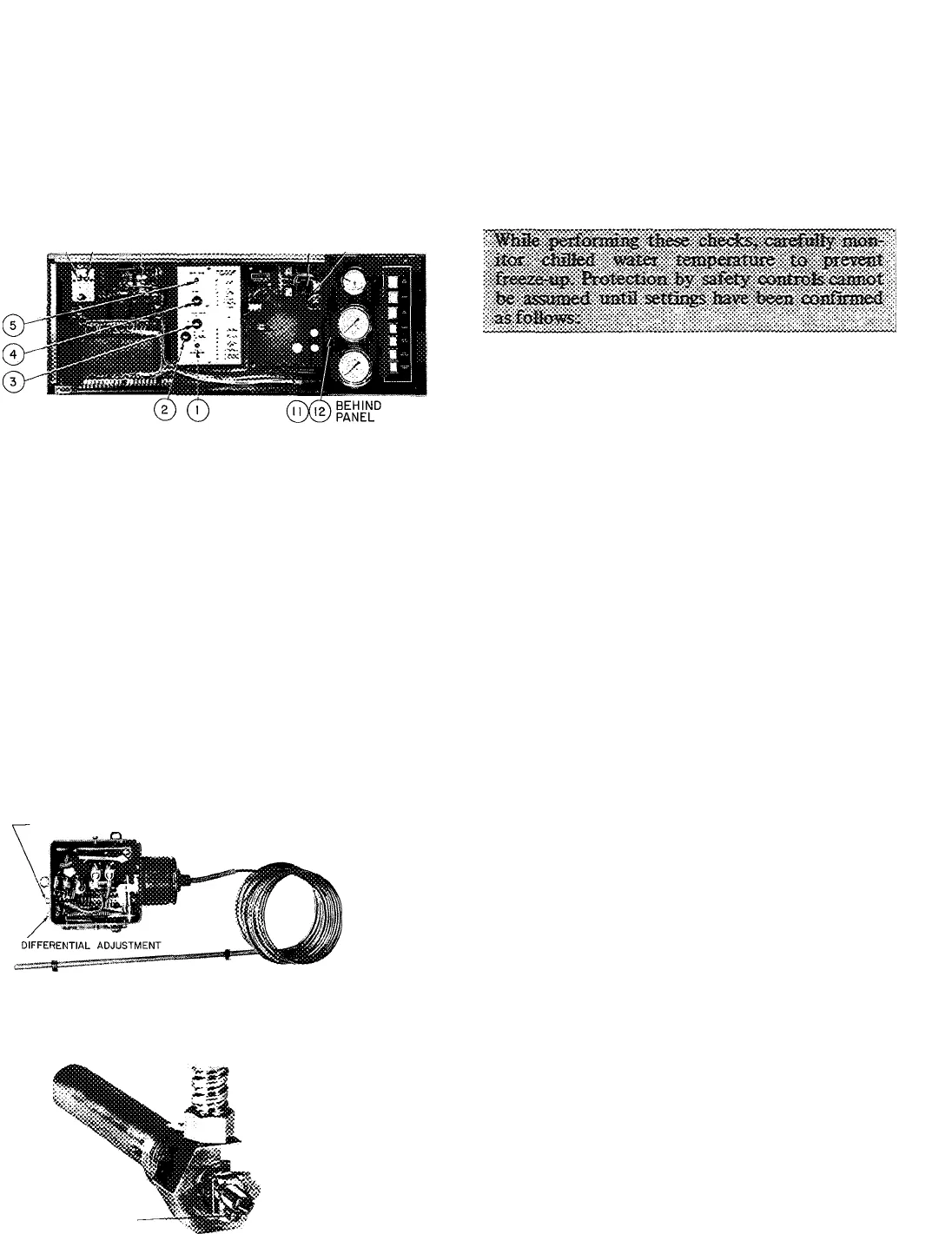

1. Chilled Water Low-Temperature Cutout

and Recycle Switch (Fig. 1)

-TEMPERATURE ADJUSTMENT

1. Set this switch to break at approximately 5 F below design chilled water

temperature, or at 36 F, whichever is higher

2. Set the differential at 10F±1 F so that whep the machine shuts down

automatically at approximately 5 F below the design chilled water tempera

ture it will restart at approximately 5 F above the design water temperature.

3. This control must break ahead of the cooler low-pressure cutout or the

machine will not recycle automatically

Perform checks 2 and 3 with machine stopped and jumper removed

2. Oil Heater Thermostat (Fig. 1)

.adjusting

"fcT'- / SCREW

»

LOCKING

SCREW

Set the oil heater thermostat to maintain a minimum oil reservoir temperature of

145 F at shutdown