ISOLATION VALVE OPERATION

Opening — Compressor must be off and vessel

pressures equalized (see Return Refrigerant to

Normal Operating Condition, steps 1 thru 6).

^. Loosen packing nut 1/2 to 1 turn so valve stem

will rotate and slide smoothly in packing. Do

not let refrigerant trapped in valve body escape.

2. Hold stem in against line pressure and rotate

stem counterclockwise as far as possible.

3. Slide stem out of body.

4i Rotate stem clockwise in the out position, until

snug.

5. Tighten packing nut.

Closing

1. Loosen packing nut 1/2 to 1 turn so valve stem

will rotate and slide smoothly in packing. Do

not let refrigerant trapped in valve body escape.

2. Rotate valve stem counterclockwise as far as

possible.

3. Slide stem into valve until it bottoms.

4. Rotate stem clockwise, holding assembly in,

until it is tight (25 ft-lb).

5. Tighten packing nut.

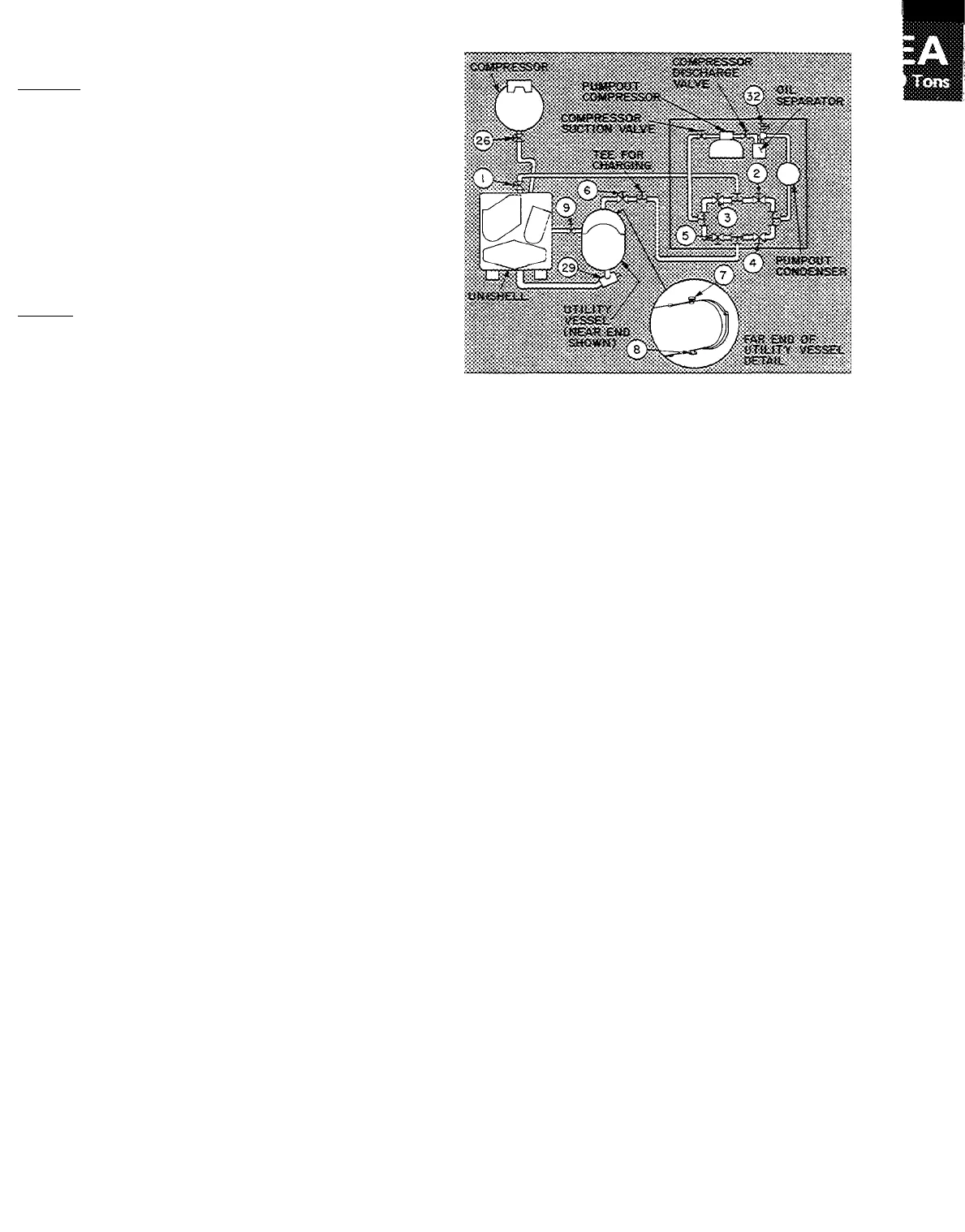

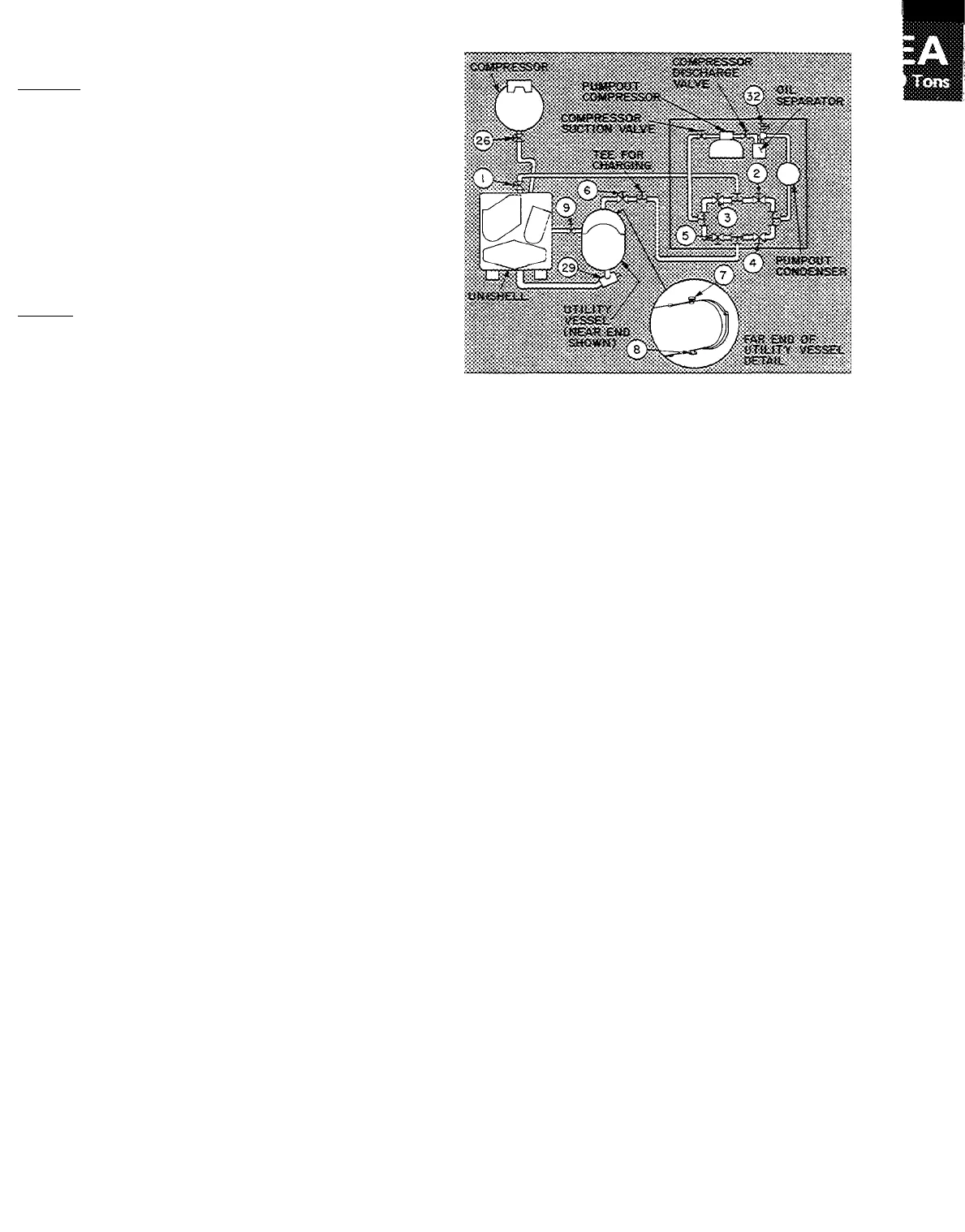

TRANSFER REFRIGERANT FROM UTILITY

VESSEL TO UNI SHELL* from normal operating

condition.

1. Add manometer near charging valve 6.

2. Close isolation valves (27), (28), and (30).

3. Open valves 1, 3, 4, 6, 7 and 8.

4. Close valves 2, 5 and 9.

5. Ensure that pumpout condenser water is off.

6. Turn on pumpout compressor until liquid is

out of utility vessel.

7. Turn off pumpout compressor.

8. Close isolation valve (29).

9. Close valves 3 and 4.

10. Open valves 1,2, 5 and 6.

11. Turn on pumpout condenser water.

12. Run pumpout compressor until utility vessel

pressure reaches 25 in. Hg, ref 30-in. bar. (2.5

psia).

13. Turn off pumpout compressor.

14. Close valves 1, 2, 5 and 6.

15. Turn off pumpout condenser water.

TRANSFER REFRIGERANT FROM UNISHELL

TO UTILITY VESSEL* from normal operating

condition.

1. Open drain valve (26).

2. Wait one hour; close isolation valves (27), (28)

and (30).

3. Open valves 1,2, 5, 6, 7 and 8.

4. Close valves 3 and 4.

5. Ensure that pumpout condenser water is off.

6. Turn on pumpout compressor for 20 minutes.

7. Turn off pumpout compressor.

8. Close isolation valve (29).

Close valves 2 and 5.

10. Open valves 1, 3, 4 and 6.

11. Turn on cooler and condenser pumps and

pumpout condenser water.

Fig. 2 — Pumpout System Schematic

(See Fig. 1 Legend for Item Ref)

12. Run pumpout compressor until unishell pres

sure reaches 25 in. Hg, ref 30-in. bar. (2.5

psia). Use dehydrator gage (34) for pressure

reading.

13. Turn off pumpout compressor.

14. Close valves 1, 3, 4 and 6.

15. Turn off pumpout condenser water.

UTILITY VESSEL EVACUATING PROCEDURE*

1. Close valves 1,2, 3, 4 and 9.

2. Open valves 5,6,1 and 8.

3. Open vent valve (32) and remove flare cap.

4. Turn off pumpout condenser water.

5. Operate pumpout compressor until manometer

reads 25 in. Hg, ref 30-in. bar. (2.5 psia).

6. Close valves 5, 6, 7 and 8.

7. Shut off pumpout compressor.

8. Close vent valve (32) and replace flare cap.

UNISHELL EVACUATING PROCEDURE*

1. Close valves 2, 4, 6 and 9.

2. Open valves 1, 3 and 5.

3. Open vent valve (32) and remove flare cap.

4. Turn off pumpout condenser water.

5. Operate pumpout compressor until manometer

reads 25 in. Hg, ref 30-in. bar. (2.5 psia).

6. Close valves 1, 3 and 5.

7. Shut off pumpout compressor.

8. Close vent valve (32) and replace flare cap.

RETURN REFRIGERANT TO NORMAL OPER

ATING CONDITION *

1. Ensure that opened vessel has been evacuated.

2. Close valves 3, 4 and 5.

3. Open valves 1,2, 6, 7 and 8.

4. Run water pumps.

5a. If unishell has been evacuated — Crack open

valve 4, gradually increasing pressure in uni

shell to 35 psig. Feed refrigerant slowly to

prevent tube freeze-up.

*See Fig 1 and 2 for all numbered references.