AFTER FIRST USE

• Check for any loose or damaged parts

after each use.

• Tighten any loose fasteners,

• Check and maintain the auger.

AFTER EACH USE

• Remove all snow and slush off the snow

thrower to prevent freezing of auger or

controls.

• Check controls to make sure they are

functioning properly.

• If any parts are worn or damaged, replace

immediately.

SNOW THROWER

LUBRICATION - EVERY 10 HOURS

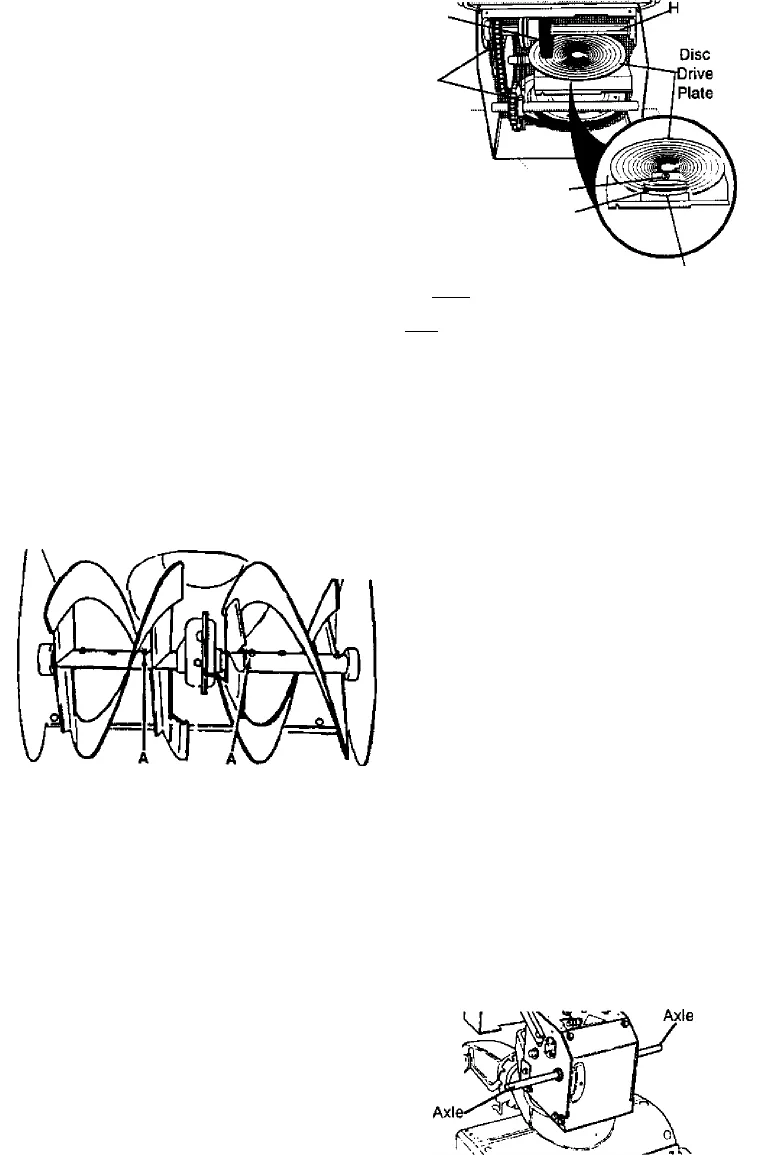

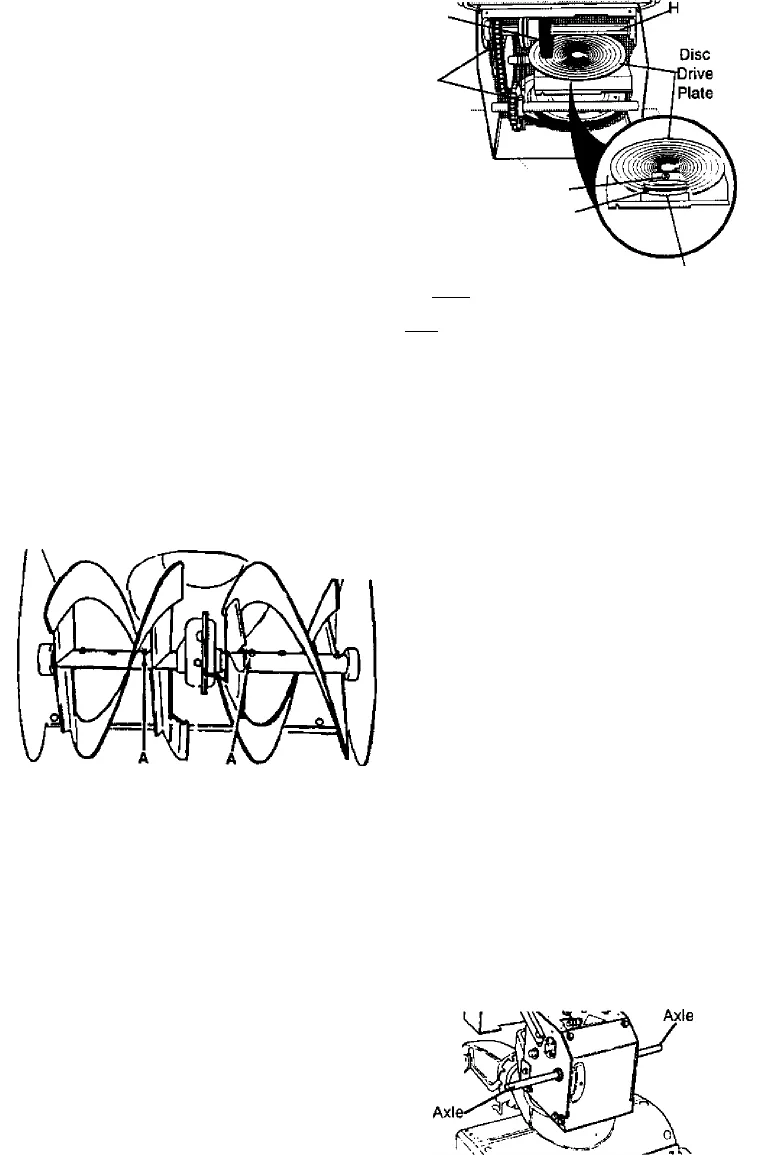

• Auger Shaft - Using a hand grease gun,

lubricate the auger shaft zerk fittings (See

figure below) every ten (10) operating

hours. Each time a shear bolt is replaced

(See To Replace Auger Shear Bolt on

page 22), the auger shaft MUST be

greased.

SNOW THROWER

• For storage or when replacing shear

bolts, remove shear bolts and lubricate

auger shaft zerks. Rotate augers several

times on the shaft and reinstall the shear

bolts.

• See Lubrication Chart diagram on page

15 for lubrication points and type of lubri

cant.

LUBRICATION - EVERY 25 HOURS

• Lubricate Disc Drive Plate every twenty-

five (25) hours and at the end of the sea

son and/or before storage.

To Lubricate:

• Position speed selector lever in first gear.

• Stand the snow thrower up on the auger

housing end.

Rubber

Friction

Wheel

Gears

(Require

No .

Lubrication)

Friction _ _ ,

Wheel Grease Zerk-

^ Bearing Assembly-

Place coin In gap

between friction

wheel and disc drive

opiate

ex

Shaft

Point at which grease

should be visible

I e-—i—Grease Zerk

• Remove the bottom panel (see second

figure on page 20).

• Turn disc drive plate clockwise by hand

until grease zerk is clearly visible at front

center. See figure above.

• Place a coin or (a shim of equal thick

ness) between the rubber friction wheel

and disc drive plate to prevent rubber fric

tion wheel contacting the drive disc.

• To grease zerk, use a hand grease gun,

lubricate with a Hi Temp EP Moly grease

See inset of figure above. DO NOT over

fill or allow grease to come in contact with

the disc drive plate or friction wheel or

damage will result. Fill zerk only until

grease becomes visible below bearing as

sembly located under grease zerk see in

sert above.

IMPORTANT: Remove coin and ensure that

a gap exists between friction wheel and disc

drive plate.

NOTE: Clean all excess grease found on

friction disc hub.

CAUTION: Do not allow grease to contact

friction wheel and disc drive plate.

LUBRICATION - BEFORE STORAGE

• Remove both wheels, grease (any auto

motive type grease) both axles, see figure

below, and replace wheels. Do this at

least once a year and/or prior to storage.