1-30

GROUP 1-ENGINES

AND

EXHAUST SYSTEMS

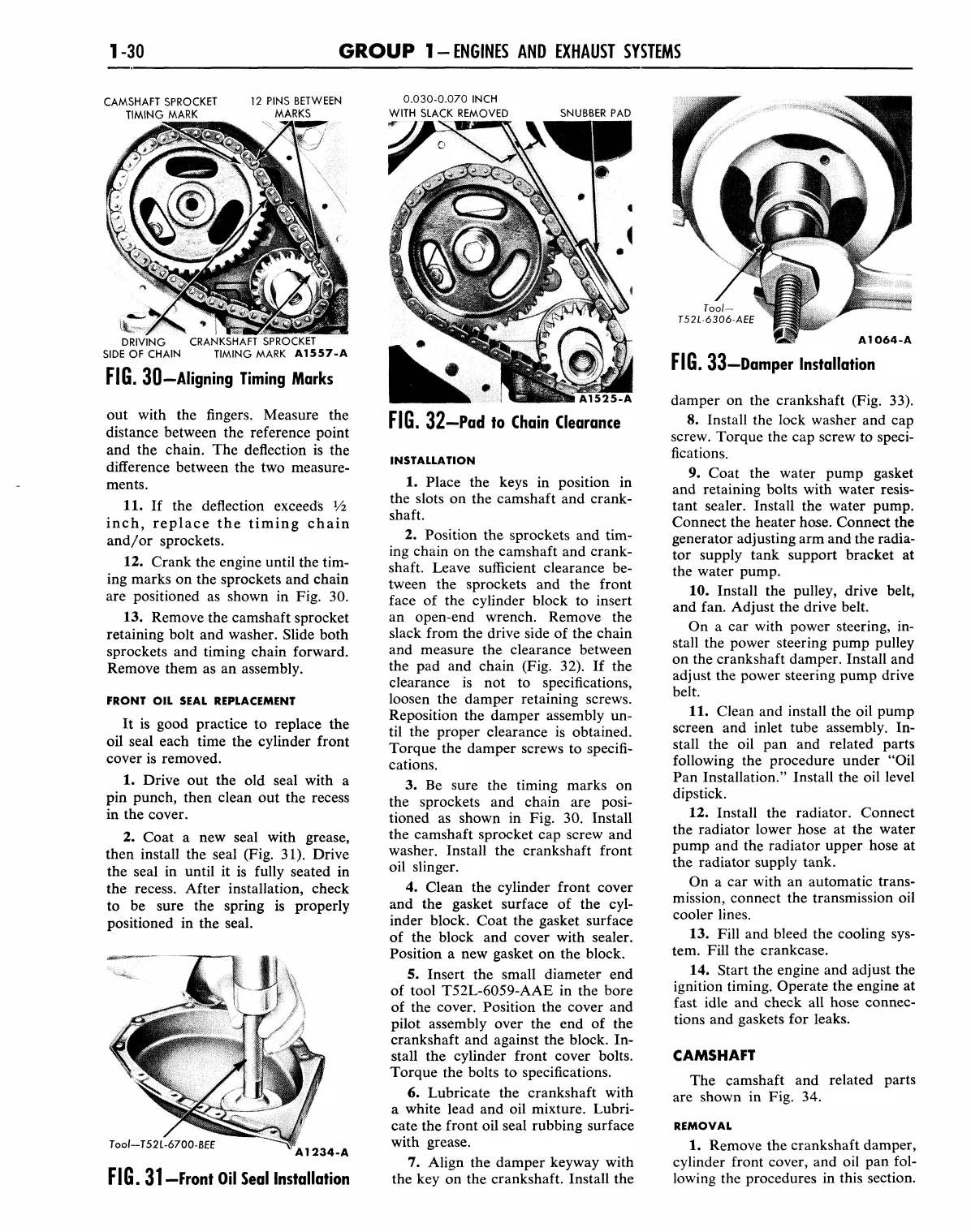

CAMSHAFT SPROCKET

TIMING MARK

12 PINS BETWEEN

MARKS

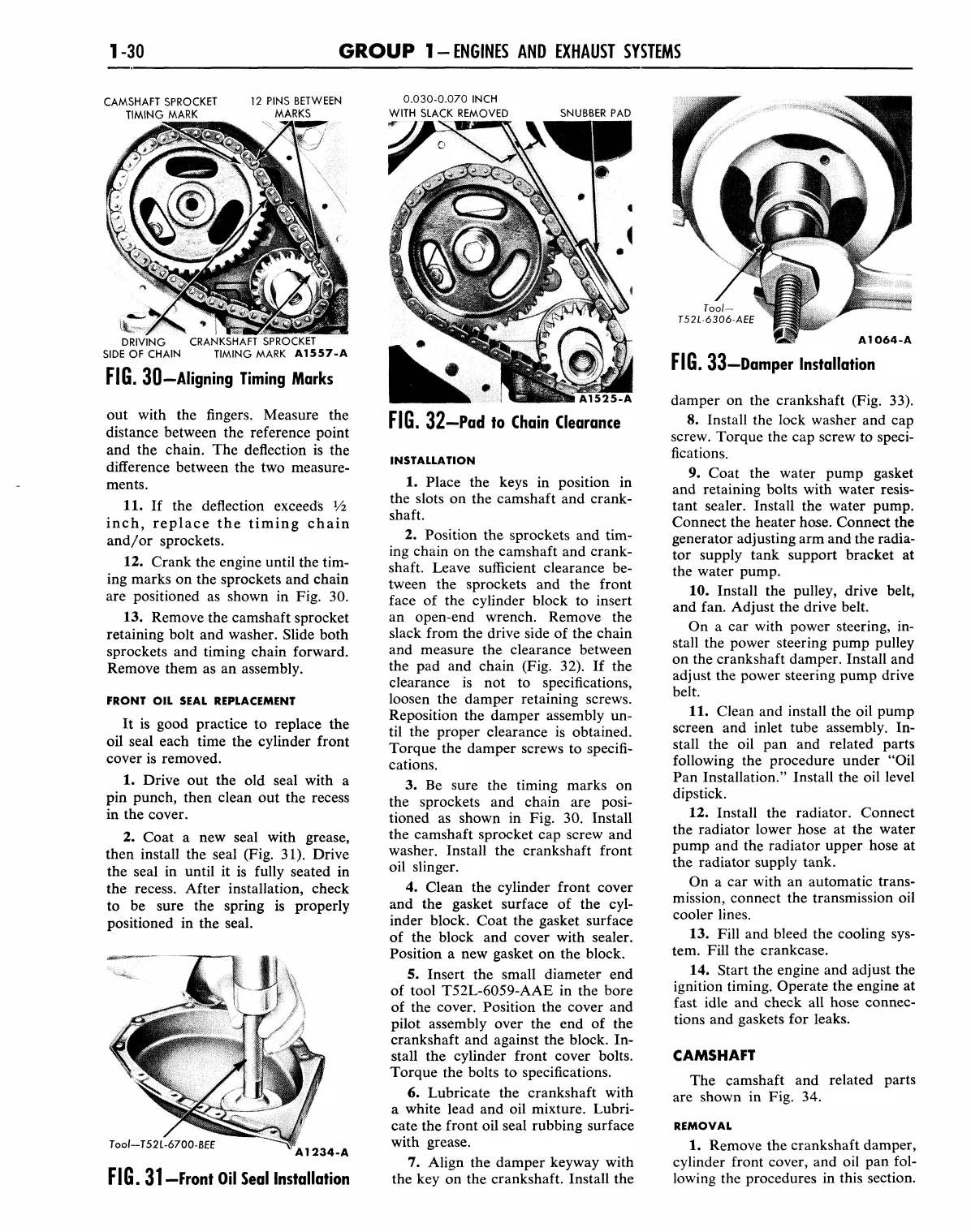

0.030-0.070 INCH

WITH SLACK REMOVED SNUBBER

PAD

DRIVING CRANKSHAFT SPROCKET

SIDE

OF

CHAIN TIMING MARK A1557-A

FIG. 30—

Aligning Timing Marks

out with the fingers. Measure the

distance between the reference point

and the chain. The deflection is the

difference between the two measure-

ments.

11.

If the deflection exceeds Vi

inch, replace the timing chain

and/or sprockets.

12.

Crank the engine until the tim-

ing marks on the sprockets and chain

are positioned as shown in Fig. 30.

13.

Remove the camshaft sprocket

retaining bolt and washer. Slide both

sprockets and timing chain forward.

Remove them as an assembly.

FRONT

OIL

SEAL REPLACEMENT

It is good practice to replace the

oil seal each time the cylinder front

cover is removed.

1.

Drive out the old seal with a

pin punch, then clean out the recess

in the cover.

2.

Coat a new seal with grease,

then install the seal (Fig. 31). Drive

the seal in until it is fully seated in

the recess. After installation, check

to be sure the spring is properly

positioned in the seal.

Tool-T52L-6700-BEE

A1234-A

FIG.

31-Front Oil Seal Installation

A1525-A

FIG.

32-Pad

to

Chain Clearance

INSTALLATION

1.

Place the keys in position in

the slots on the camshaft and crank-

shaft.

2.

Position the sprockets and tim-

ing chain on the camshaft and crank-

shaft. Leave sufficient clearance be-

tween the sprockets and the front

face of the cylinder block to insert

an open-end wrench. Remove the

slack from the drive side of the chain

and measure the clearance between

the pad and chain (Fig. 32). If the

clearance is not to specifications,

loosen the damper retaining screws.

Reposition the damper assembly un-

til the proper clearance is obtained.

Torque the damper screws to specifi-

cations.

3.

Be sure the timing marks on

the sprockets and chain are posi-

tioned as shown in Fig. 30. Install

the camshaft sprocket cap screw and

washer. Install the crankshaft front

oil slinger.

4.

Clean the cylinder front cover

and the gasket surface of the cyl-

inder block. Coat the gasket surface

of the block and cover with sealer.

Position a new gasket on the block.

5.

Insert the small diameter end

of tool T52L-6059-AAE in the bore

of the cover. Position the cover and

pilot assembly over the end of the

crankshaft and against the block. In-

stall the cylinder front cover bolts.

Torque the bolts to specifications.

6. Lubricate the crankshaft with

a white lead and oil mixture. Lubri-

cate the front oil seal rubbing surface

with grease.

7.

Align the damper keyway with

the key on the crankshaft. Install the

Tool-

T52L-6306-AEE

A1064-A

FIG.

33—Damper Installation

damper on the crankshaft (Fig. 33).

8. Install the lock washer and cap

screw. Torque the cap screw to speci-

fications.

9. Coat the water pump gasket

and retaining bolts with water resis-

tant sealer. Install the water pump.

Connect the heater hose. Connect the

generator adjusting arm and the radia-

tor supply tank support bracket at

the water pump.

10.

Install the pulley, drive belt,

and fan. Adjust the drive belt.

On a car with power steering, in-

stall the power steering pump pulley

on the crankshaft damper. Install and

adjust the power steering pump drive

belt.

11.

Clean and install the oil pump

screen and inlet tube assembly. In-

stall the oil pan and related parts

following the procedure under "Oil

Pan Installation." Install the oil level

dipstick.

12.

Install the radiator. Connect

the radiator lower hose at the water

pump and the radiator upper hose at

the radiator supply tank.

On a car with an automatic trans-

mission, connect the transmission oil

cooler lines.

13.

Fill and bleed the cooling sys-

tem. Fill the crankcase.

14.

Start the engine and adjust the

ignition timing. Operate the engine at

fast idle and check all hose connec-

tions and gaskets for leaks.

CAMSHAFT

The camshaft and related parts

are shown in Fig. 34.

REMOVAL

1.

Remove the crankshaft damper,

cylinder front cover, and oil pan fol-

lowing the procedures in this section.