PART 1-2-MILEAGE MAKER SIX

1-29

UNDERSIDE

OF

SPRING RETAINER

SURFACE

OF

SPRING

PAD

A104 7-A

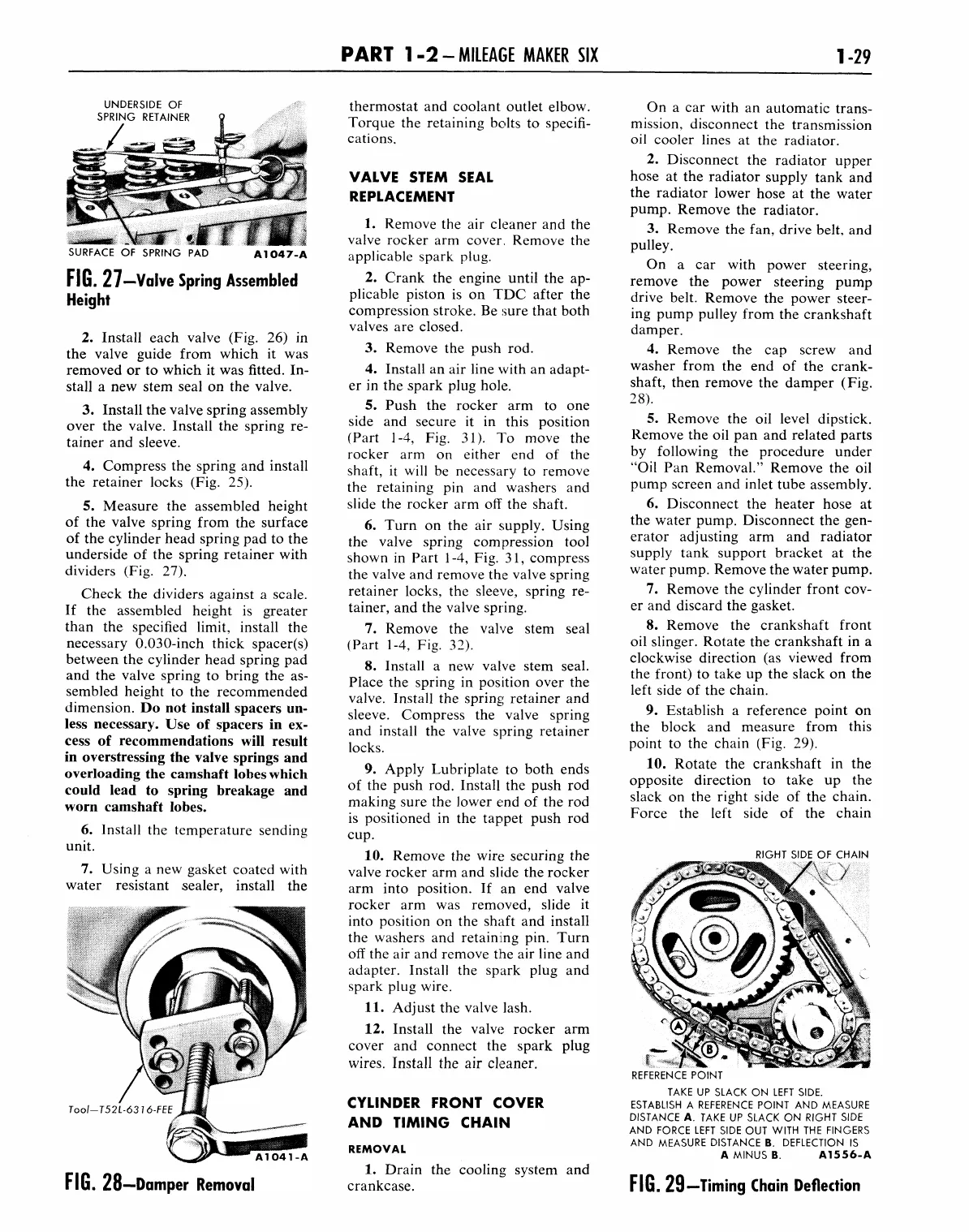

FIG.

27—Valve Spring Assembled

Height

2.

Install each valve (Fig. 26)

in

the valve guide from which

it

was

removed or to which it was

fitted.

In-

stall

a

new stem seal on the valve.

3.

Install the valve spring assembly

over the valve. Install the spring re-

tainer and sleeve.

4.

Compress the spring and install

the retainer locks (Fig. 25).

5.

Measure the assembled height

of the valve spring from the surface

of the cylinder head spring pad to the

underside

of

the spring retainer with

dividers (Fig. 27).

Check the dividers against

a

scale.

If

the

assembled height

is

greater

than

the

specified limit, install

the

necessary 0.030-inch thick spacer(s)

between the cylinder head spring pad

and the valve spring to bring the as-

sembled height to the recommended

dimension. Do not install spacers un-

less necessary. Use

of

spacers

in

ex-

cess

of

recommendations will result

in overstressing the valve springs and

overloading the camshaft lobes which

could lead

to

spring breakage

and

worn camshaft lobes.

6. Install the temperature sending

unit.

7.

Using a new gasket coated with

water resistant sealer, install

the

Tool-T52L-6316-FEE

h

A1041-A

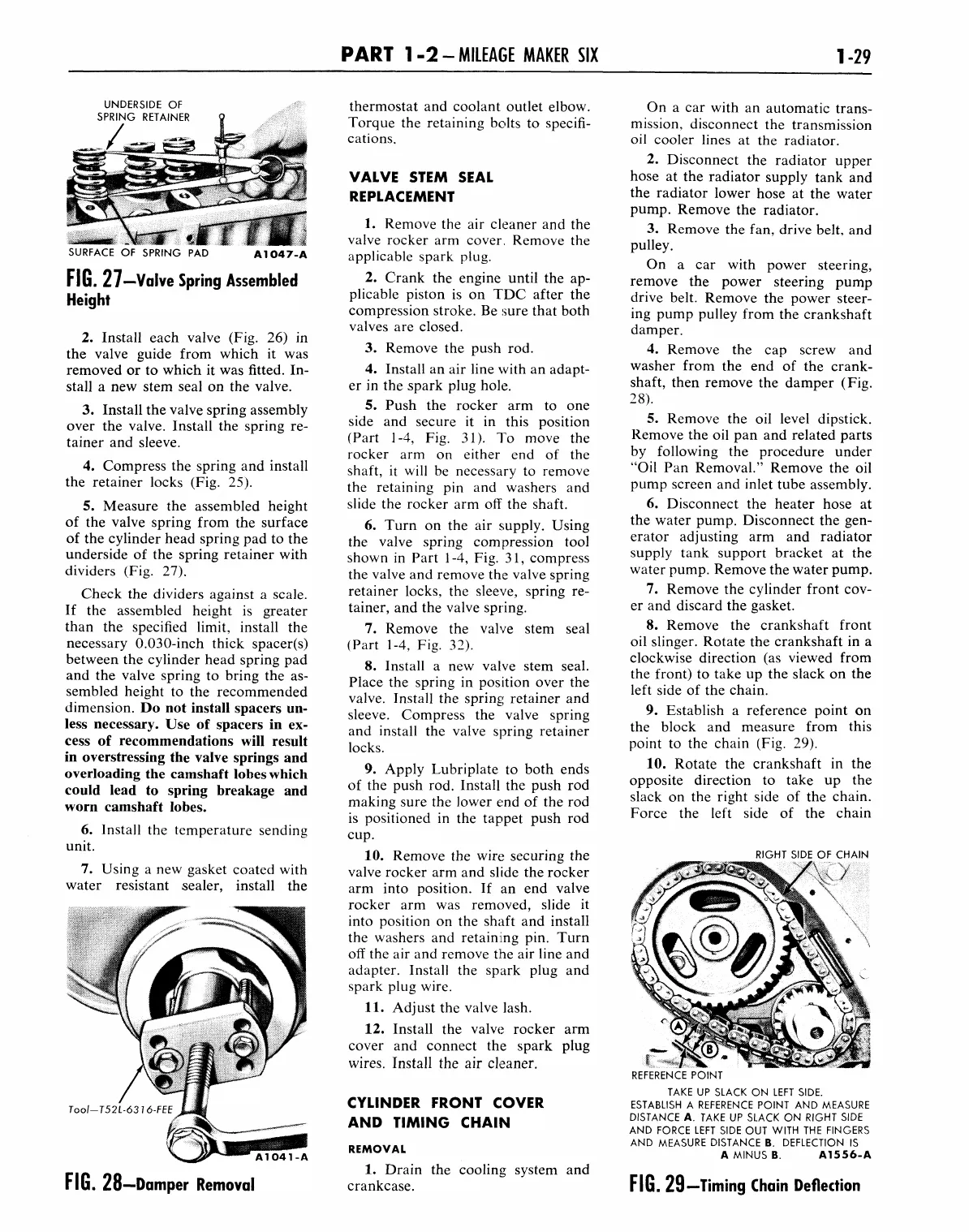

FIG.

28—Damper Removal

thermostat and coolant outlet elbow.

Torque the retaining bolts to specifi-

cations.

VALVE STEM SEAL

REPLACEMENT

1.

Remove the air cleaner and the

valve rocker arm cover. Remove the

applicable spark plug.

2.

Crank the engine until the ap-

plicable piston

is

on TDC after the

compression stroke. Be sure that both

valves are closed.

3.

Remove the push rod.

4.

Install an air line with an adapt-

er in the spark plug hole.

5.

Push

the

rocker arm

to one

side and secure

it in

this position

(Part

1-4,

Fig. 31).

To

move

the

rocker

arm on

either

end of the

shaft,

it

will be necessary to remove

the retaining

pin and

washers

and

slide the rocker arm off the shaft.

6. Turn on the air supply. Using

the valve spring compression tool

shown in Part 1-4, Fig. 31, compress

the valve and remove the valve spring

retainer locks, the sleeve, spring re-

tainer, and the valve spring.

7.

Remove

the

valve stem seal

(Part 1-4, Fig. 32).

8. Install

a

new valve stem seal.

Place the spring in position over the

valve. Install the spring retainer and

sleeve. Compress

the

valve spring

and install the valve spring retainer

locks.

9. Apply Lubriplate

to

both ends

of the push rod. Install the push rod

making sure the lower end of the rod

is positioned

in

the tappet push rod

cup.

10.

Remove the wire securing the

valve rocker arm and slide the rocker

arm into position.

If an

end valve

rocker arm was removed, slide

it

into position on the shaft and install

the washers and retaining pin. Turn

off the air and remove the air line and

adapter. Install the spark plug and

spark plug wire.

11.

Adjust the valve lash.

12.

Install

the

valve rocker arm

cover

and

connect

the

spark plug

wires.

Install the air cleaner.

CYLINDER FRONT COVER

AND TIMING CHAIN

REMOVAL

1.

Drain the cooling system and

crankcase.

On

a

car with an automatic trans-

mission, disconnect the transmission

oil cooler lines

at

the radiator.

2.

Disconnect the radiator upper

hose at the radiator supply tank and

the radiator lower hose

at

the water

pump. Remove the radiator.

3.

Remove the fan, drive belt, and

pulley.

On

a car

with power steering,

remove

the

power steering pump

drive belt. Remove the power steer-

ing pump pulley from the crankshaft

damper.

4.

Remove

the cap

screw

and

washer from the end

of

the crank-

shaft, then remove the damper (Fig.

28).

5.

Remove the

oil

level dipstick.

Remove the oil pan and related parts

by following

the

procedure under

"Oil Pan Removal." Remove the oil

pump screen and inlet tube assembly.

6. Disconnect the heater hose

at

the water pump. Disconnect the gen-

erator adjusting

arm and

radiator

supply tank support bracket

at the

water pump. Remove the water pump.

7.

Remove the cylinder front cov-

er and discard the gasket.

8. Remove

the

crankshaft front

oil slinger. Rotate the crankshaft in

a

clockwise direction (as viewed from

the front) to take up the slack on the

left side of the chain.

9. Establish

a

reference point on

the block

and

measure from this

point

to

the chain (Fig. 29).

10.

Rotate the crankshaft

in the

opposite direction

to

take

up the

slack on the right side

of

the chain.

Force

the

left side

of the

chain

RIGHT SIDE OF CHAIN

f

*-•

REFERENCE POINT

TAKE UP SLACK ON LEFT SIDE.

ESTABLISH

A

REFERENCE POINT AND MEASURE

DISTANCE A. TAKE UP SLACK ON RIGHT SIDE

AND FORCE LEFT SIDE OUT WITH THE FINGERS

AND MEASURE DISTANCE

B.

DEFLECTION

IS

A MINUS B.

A1556-A

FIG.

29—Timing Chain Deflection