10. Method for shell matching.

The tightening torque for installing the fixing bolt of

connecting rod bearing is 25±3Nm (then turn 90±5°

clockwise).

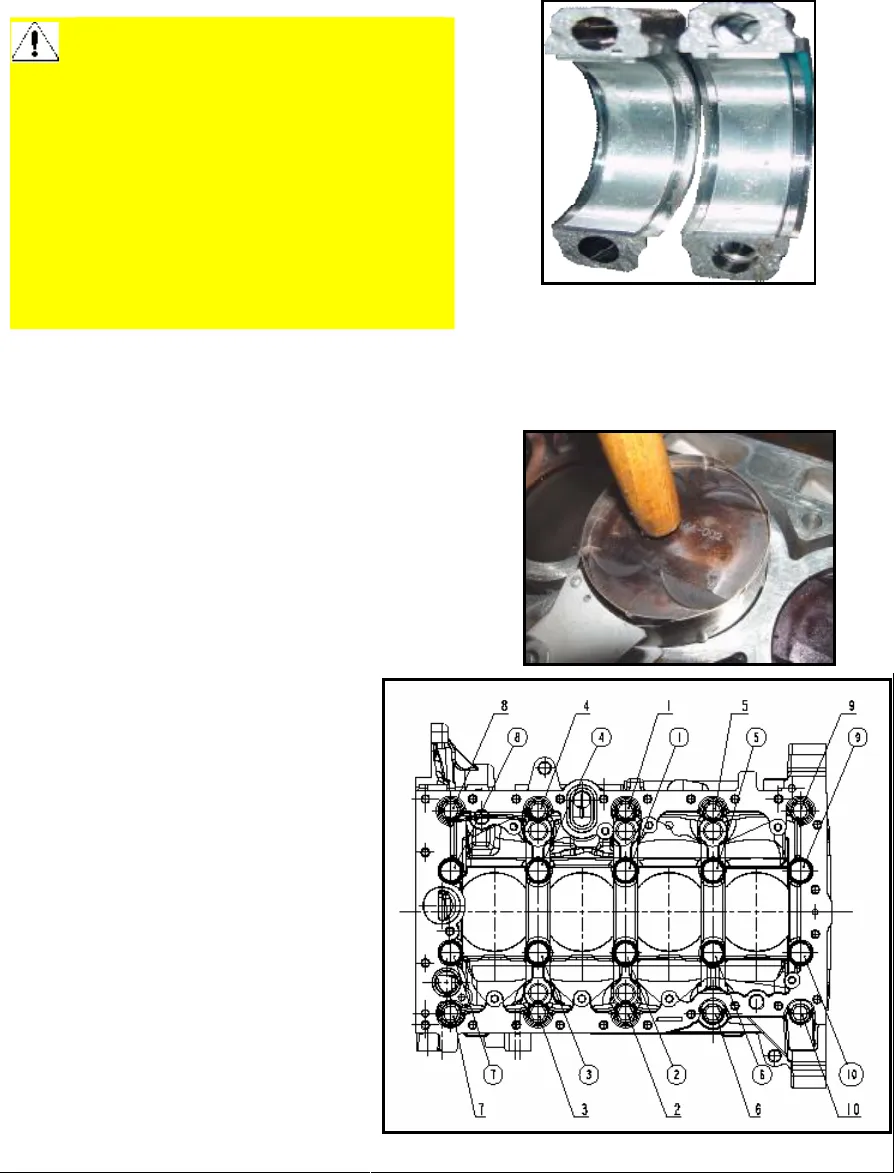

Note:

The machining technique for connecting

rod and connecting rod shell cap adopts Instantly

Swell and Break machining method, so, each

machined surface maintains the shape of original

material. When installing, keep any sundries out

of this machined surface. In addition, only the

two machined surface of the same connecting rod

can completely engage.

11. Use the piston installation special tool to install

the piston.

12. Tighten the fixing bolt of connecting

rod bearing cap.

Tightening torque:

First time: 25±3Nm. Second time: turn

90±5 °.

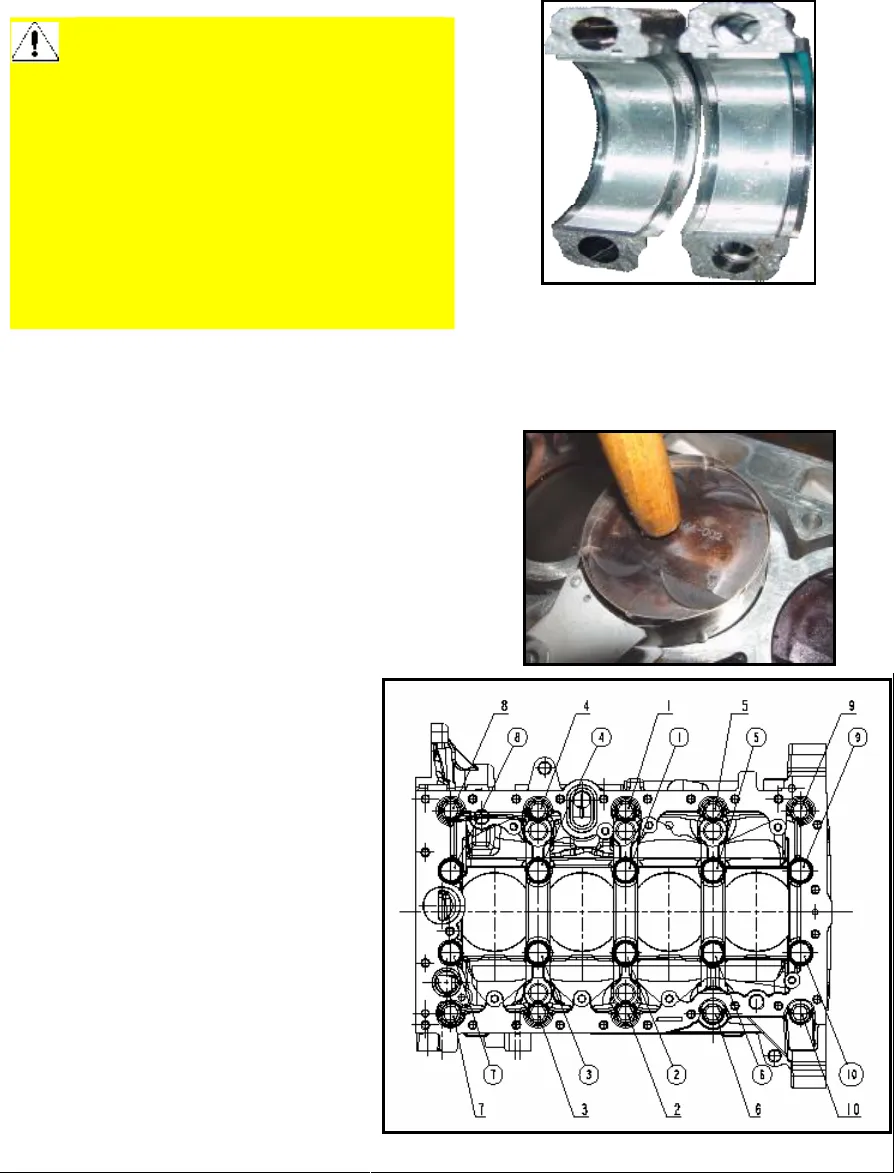

13. Install the main bearing cap and then

follow the order as shown in the figure to

tighten the bolt.

Tightening torque:

First time: 45±5Nm.

Second time: turn 180±10°.

14. Tighten the fixing bolt of main

bearing cap and cylinder block.

Torque: 20+3 Nm.