DISCHARGE

WATER

CONNECTIONS

Refrigerant Hose

Water Hose

Direct Coupled Connection

Factory-Installed Copper Tubing

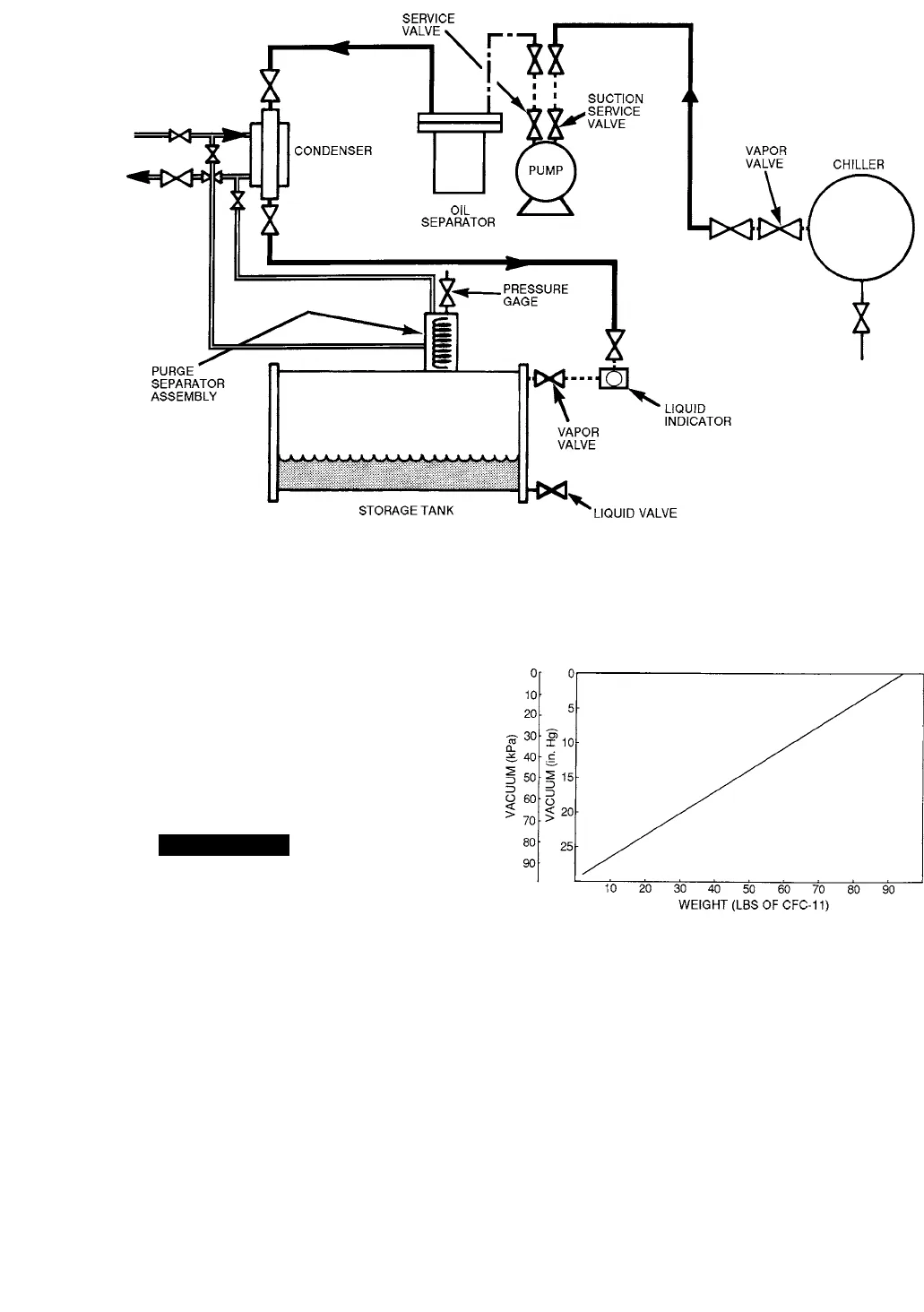

Fig. 11 — Refrigerant Vapor Transfer/Evacuation Connections

TO TRANSFER REFRIGERANT - Open all valves be

tween the chiller and storage tank. Turn on the water to the

tube-in-tube condenser. Turn on the pump. After a few min

utes, the condensed vapor will be seen in its liquid form

flowing through the liquid indicator to the storage tank. The

end of the vapor transfer can be determined by observing

the liquid indicator. When liquid is no longer visible, the

transfer is complete.

A CAUTION

Be sure to run the chiller water pumps when removing

refrigerant vapor. Trapped liquid may boil and can cause

tube freeze-up.

The vapor recovery process is complete when the vac

uum in the chiller has reached 29 in. Hg (25 mm Hg). Be

fore turning off the pump, shut off the water to the tube-

in-tube condenser and then drain the water from the condenser.

As the condenser warms up, it will help drain any liquid

remaining in the condenser and refrigerant hose into the stor

age tank. Turn off the pump. Close the valves to the stor

age tank and chiller. Disconnect the refrigerant hoses. Any

refrigerant vapor remaining in the refrigerant hoses and the

tube-in-tube condenser are considered to be de minimis. See

Fig. 12.

Use the same process when transferring vapor refrigerant

from the storage tank to the chiller.

10

20 30

WEIGHT (Kg OF CFC-11)

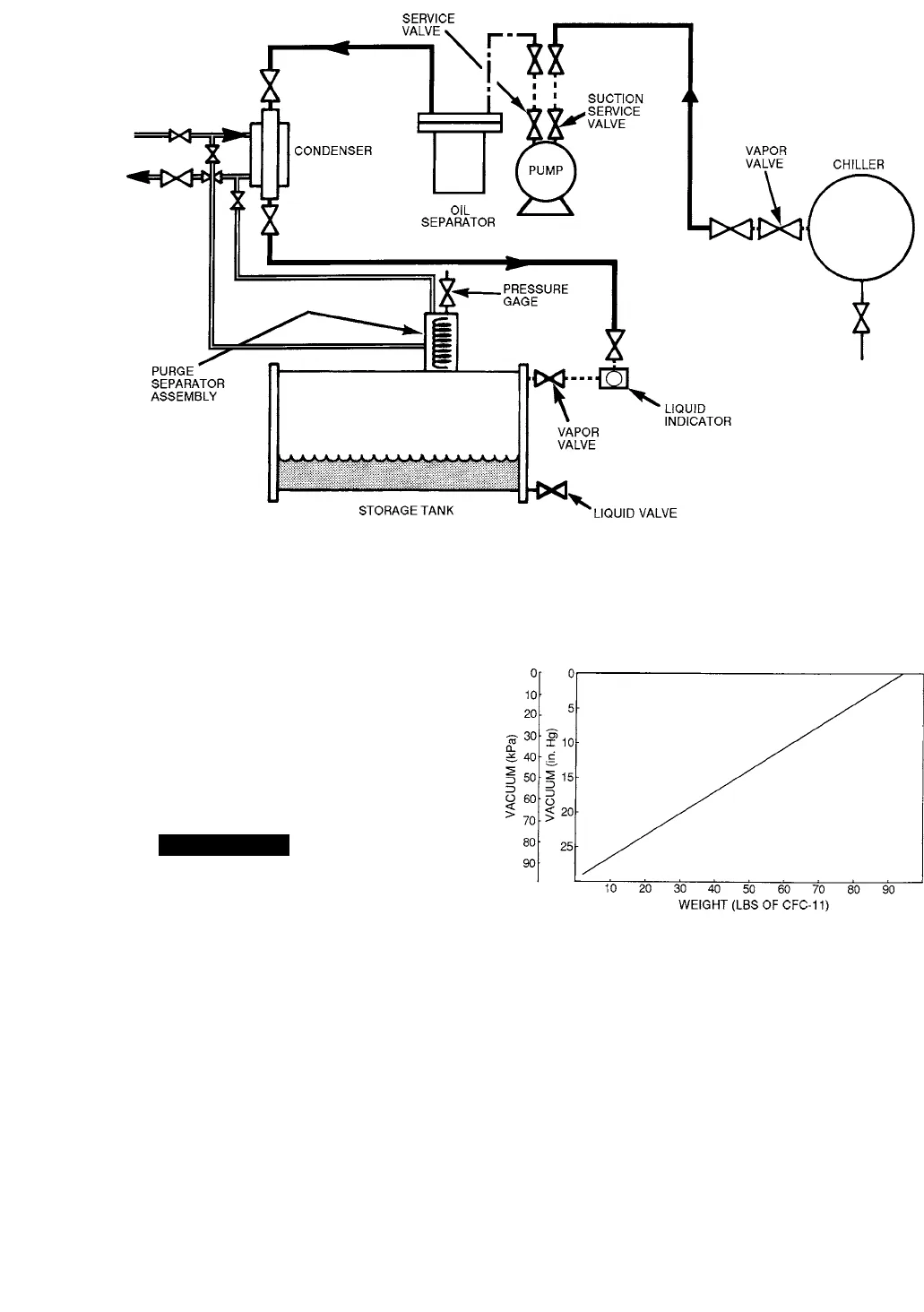

Fig. 12 — Refrigerant Vapor Remaining

in Chiller After Removal

of Liquid Refrigerant (400 Ton Unit)

40

11