COMPONENT

TEST

Before testing

any

of

"che

components, pedarm

the

folIowing

checks:

The

most common cause for control failure

is corrosion on

connectors. Therefore, dis-

connecting and reconnecting wires

will

be

necessary throughout test

p~ocedetres.

a

All

testsichecks should be rnsnde

with

a

VOM

or

DVM

having a sensitivity

of

20.1300

ohms-per-volt

DC,

or greater.

*

Check

ail connectjoras before repiacing

mrnponents: looking for broken or loose

wires, failed terminals, or wires not pressed

int~

connectors

far

enough.

Resistance checks must be made

with

power cord unphgged from outlet, and

with

wiring harness or connectors discon-

nected.

Electrical

Shock

Hazard

Disc~nnect

power

before

servicing.

Repiace

all

parts

and

panels

before

operating.

I

I

Failure

to

ds

so

can

result

in

death

or

eIec9ricai

shock.

1

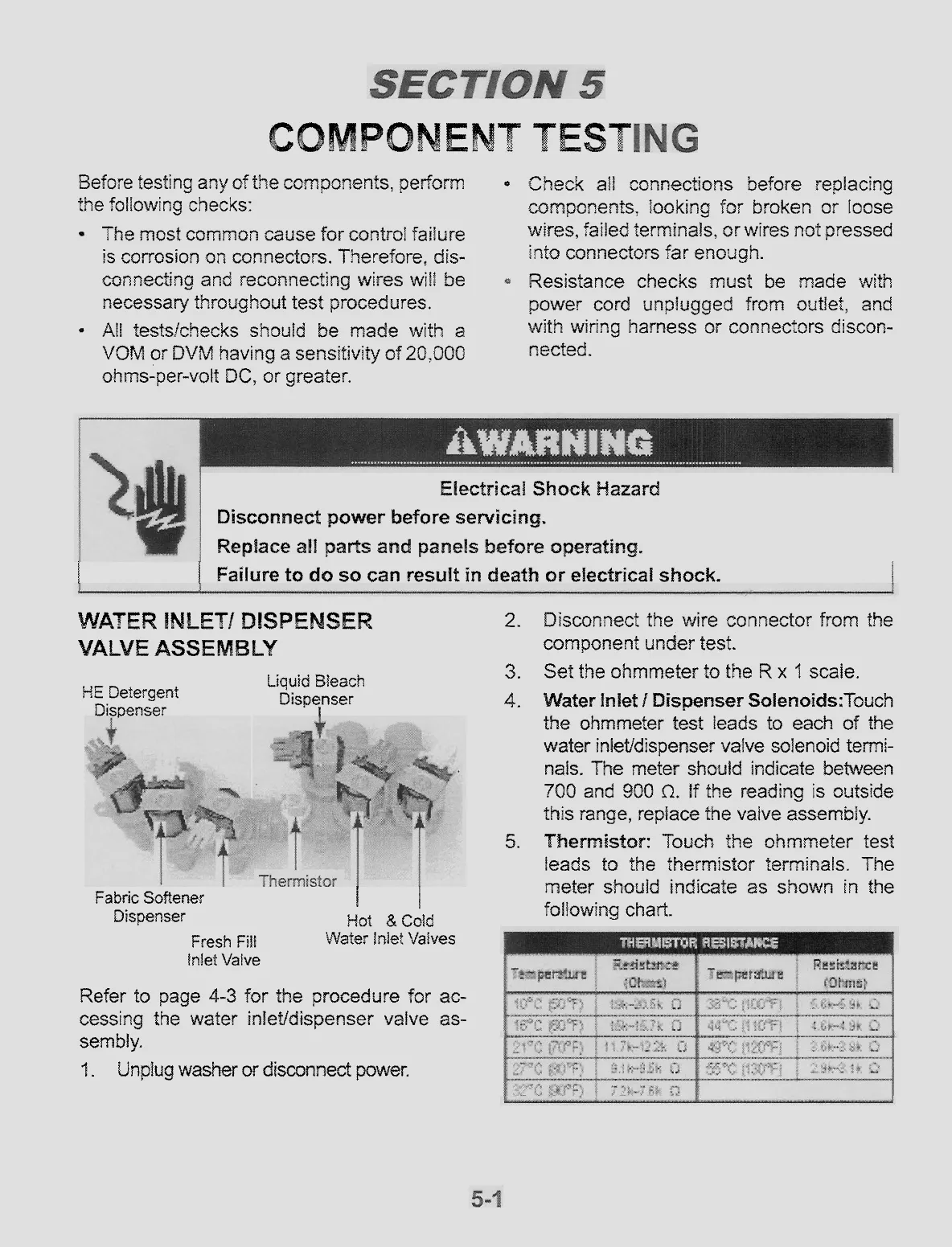

WATER

INLET/

DaSPENSER

VALVE

ASSEMBLY

HE

Detergent

Dis~enwr

Liquid

BBeach

Dispenser

I

Fabric

Sofaenea

Dispenser

a

I

Mot

B

Cold

Fresh

Fifl

Water

Iniet

Valves

tn1e-l

Vafve

Refer

to

page

4-3

for the procedure

;for

ac-

cessing the water

inlevdispenser valve

as-

sembly.

2.

Unplug

washer or disconnect power.

2.

Disconnect the wire connector from the

component under test.

3.

Set

the ohmmeter to the

R

x

-I

sca9e.

4.

Water

fnlet

f

Dispenser

Solenoids:Touch

the

ohmmeter test leads to each of the

water

insetfdispenser valve

solenoid

temi-

nals.

The

meter should indicate between

708

and

900

Q.

ff

the reading

is

outside

"chis

range, replace the valve assernbiy.

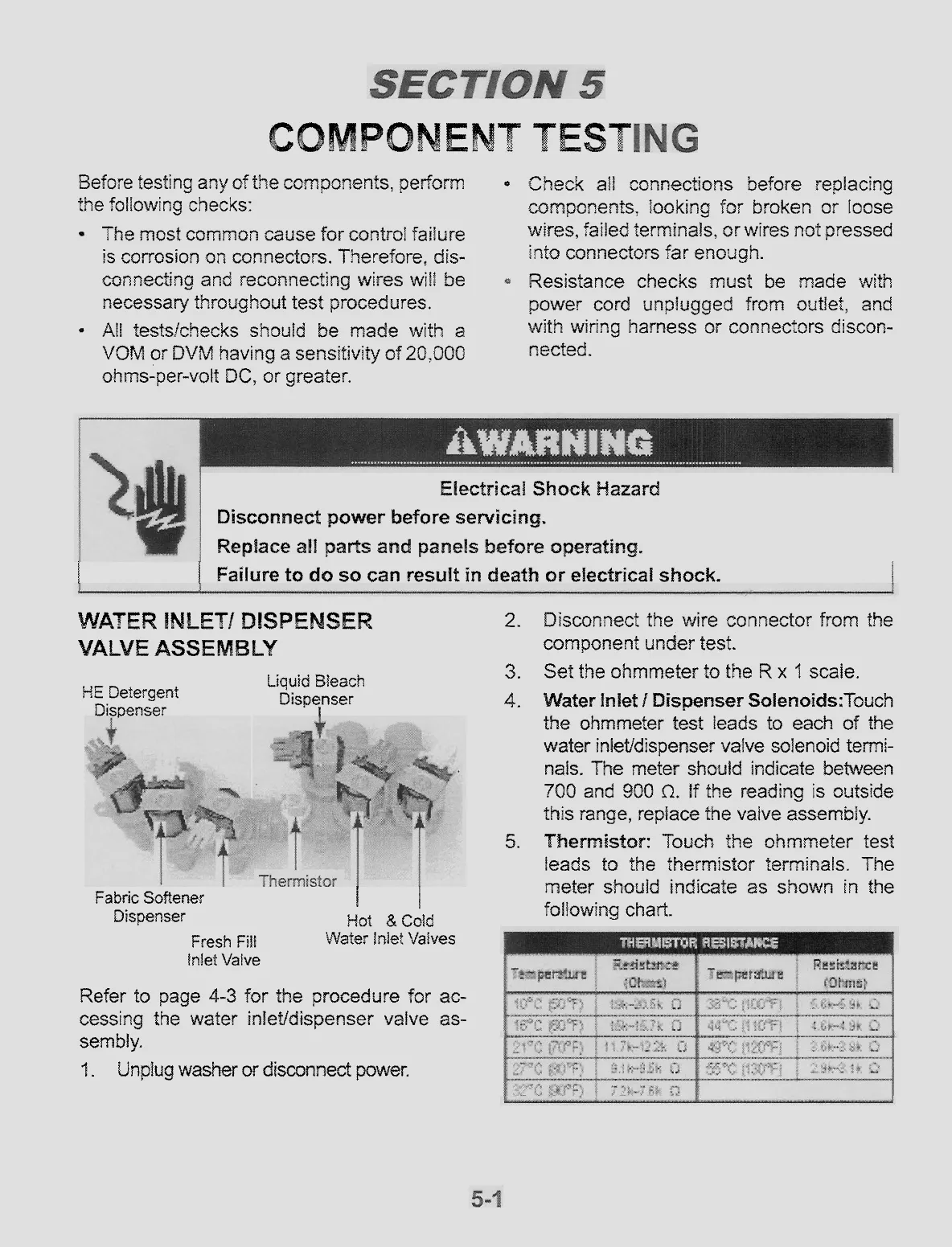

5.

Thermistor:

Touch the ohmmeter test

leads to the thermistor terminals. The

meter

should indicate as shown

in

the

fotlowing chart.