Assembly (continued)

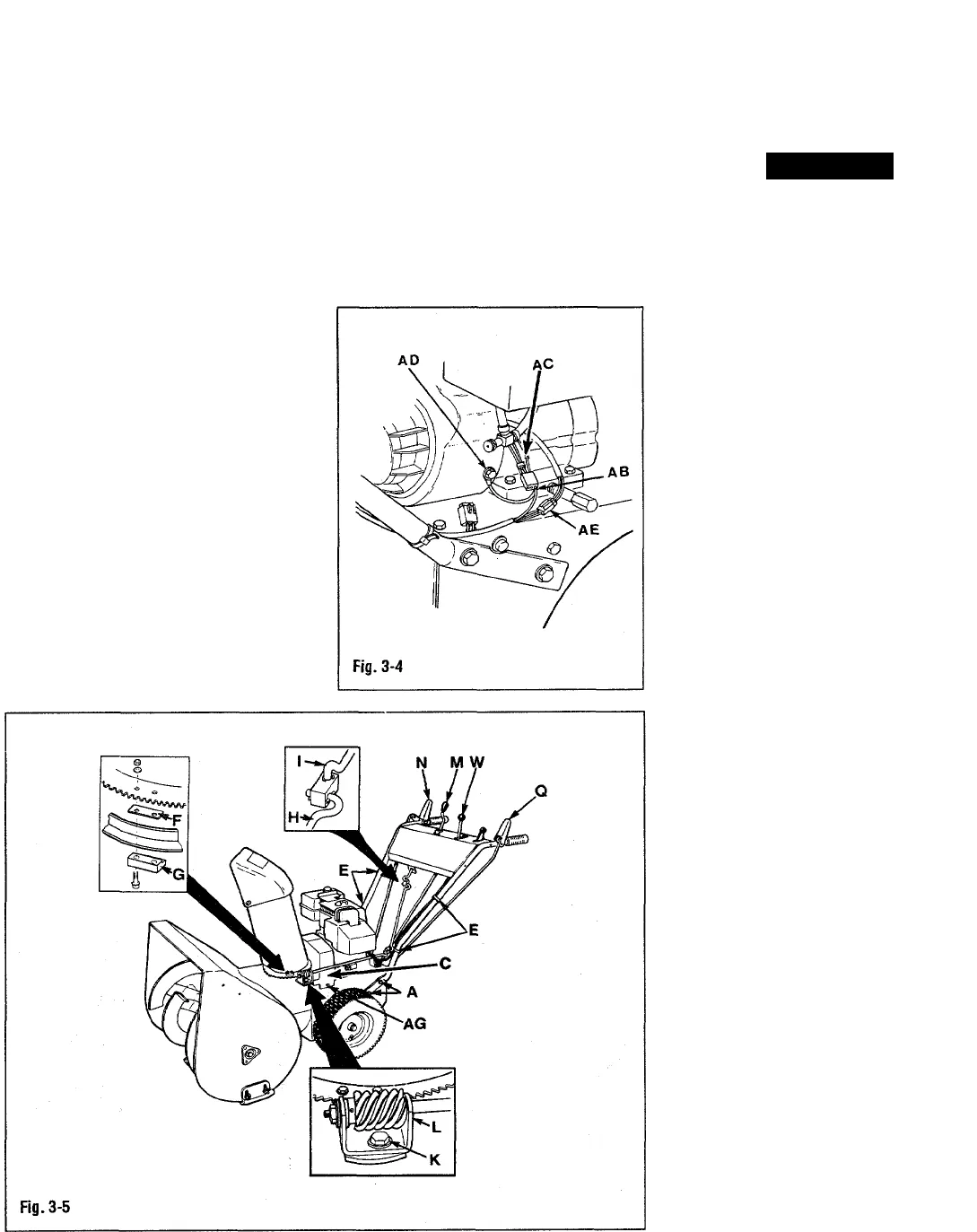

Wiring Harness Instailation

1. Connect lead wire (AB, Fig. 3-4) to

engine wiring harness connector. Plug lead

wire into connector receptacle containing

yellow wire (AC).

2. Connect eye terminal to screw (AD)

on engine shroud. Plug connector (AE)

into engine plug.

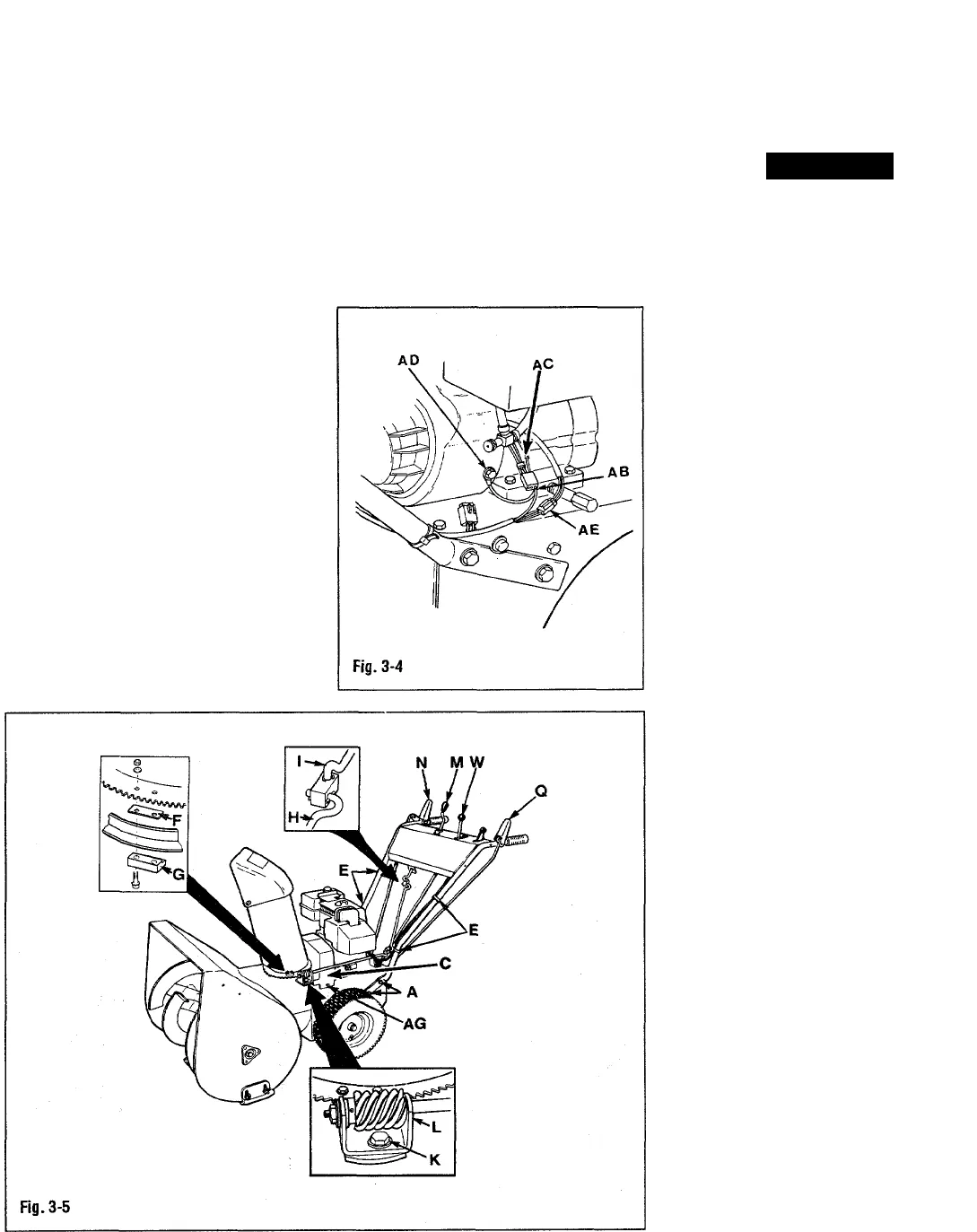

3. Secure wires to handlebars with tie

straps (E, Fig. 3-5).

Brake Arm Adjustment

1. Remove bolts securing belt cover

(AG. Fig. 3-5). Lift belt cover (C) up and off

unit.

2. Check brake arm adjustment:

A. Fully depress and hold auger

drive handlebar control lever (N). A second

person may need to hold handle down.

B. Look down through pulleys and

belts at front of engine (A, Fig. 3-6). Check

gap between brake arm (AH, Fig. 3-7) and

belt (AL). Gap should measure between

1/16" and 1/8" (1.5-3 mm).

C. To adjust gap, loosen nut (Al).

Hold set screw (AK) in place with an alien

wrench and turn nut (AJ) until proper

clearance is obtained. Retighten nut (Al).

3. Reinstall belt cover.

Engine Oil

CAUTION

Engine is shipped WITHOUT oil.

DO NOT start engine before adding

correct type and amount of engine oil.

See engine owner's manual.

1. Unscrew oil fill cap (AM, Fig. 3-8) and

place aside. Insert a clean funnel into oil filler

tube (AL).

2. Slowly pour oil of the correct type

(see engine owner's manual) through

funnel and into oil filler tube. Engine holds

approximately 26 ounces. Fill to FULL

mark on dipstick.

NOTE: DO NOT overfill. While adding

oil to engine, frequently stop and check

oil level.

Tire Pressure

1. Check tire inflation pressure.

2. To help prevent pulling to one side,

inflate both tires evenly (8 to 12 psi).

Auger Gear Case Oil

Check auger gear case oil level. See

"Lubrication" on page 16 for instructions.