C

ontraindication

The product is contraindicated

– for intraoral luting;

– if the stipulated working technique cannot be applied;

– if the patient is known to be allergic to components of Multilink Hybrid

Abutment.

Side effects

Systemic side effects are not known. In rare cases allergic reactions to

individual components have been reported.

Interactions

Phenolic substances (e.g. wintergreen oil, eugenol) inhibit polymerization.

Therefore, materials containing these components must not be used.

Oxidative disinfectants (e.g. hydrogen peroxide) may interact with the

initiator system and impair the setting process. As a result, the automix

syringe must not be disinfected with oxidative agents. The syringe can be

disinfected by wiping it with medical alcohol for example.

Application

The contact surfaces must be meticulously prepared in order to ensure an

optimum adhesive bond between the base and the ceramic structure. The

procedure is described below. The same procedure is used for the Hybrid

Abutment and the Hybrid Abutment Crown.

Hybrid abutments and hybrid abutment crowns made of

IPS e.max lithium disilicate glass-ceramics (LS

2

)

H

ybrid abutments made of zirconium oxide (ZrO

2

)

1. Preparation of the base

The following procedure should be observed in the preparation of the base

for the cementation with the ceramic structure:

– The base should be prepared according to the instructions of the manu-

facturer.

– The base is cleaned in an ultrasonic bath or with a steam cleaner and

then dried with blown air.

– The base is screwed to the model analog.

– The ceramic structure is placed on the base and the relative position is

marked with a waterproof pen. This makes it easier to attain the correct

relative end position when the parts are assembled at a later stage.

– The emergence profile of the base must not be blasted or modified in any

way!

– If the manufacturer recommends that the contact surfaces be

sandblasted, the following procedure should be observed:

– Hard modelling wax is applied to protect the emergence profile, since

this type of material is easy to remove later on.

– The screw channel is also sealed with wax.

– The bonding area surface is carefully blasted according to the

instructions of the manufacturer.

– An instrument and a steam jet are used for cleaning. The wax has

to be removed meticulously.

– After the bonding surface has been cleaned, it must not be contaminated

under any circumstances, as this would impair the bond.

– Monobond Plus is applied on the clean bonding surface and allowed to

react for 60 s. After the reaction time, any residue is dispersed with air

that is free of water and oil.

– The screw channel is sealed with a foam pellet or wax. The bonding sur-

face must not be contaminated in the process.

2. Preparation of the ceramic structure

2.1. IPS e.max lithium disilicate glass-ceramic (LS

2

)

The following procedure must be followed in the preparation of the ceramic

structure for the cementation with the base:

– The ceramic structure must not be blasted when it is prepared for

cementation.

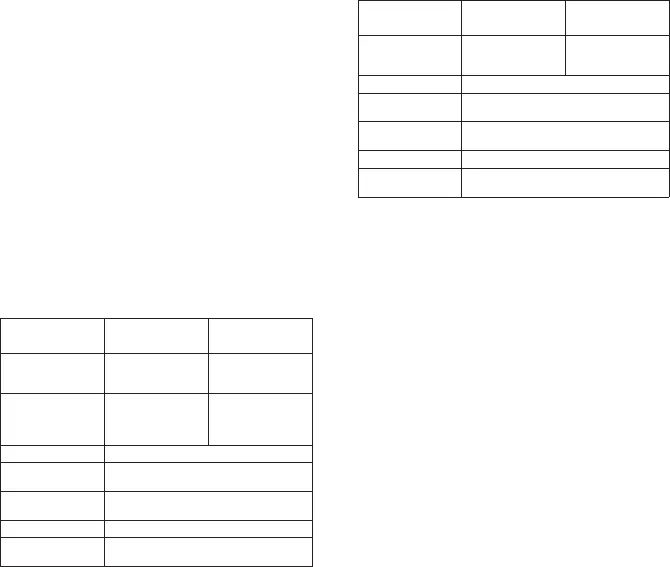

Ceramic structure

(LS

2

)

Base

Blasting –

According to the

instructions of the

manufacturer

Etching

The bonding area

is etched with

PS

®

Ceramic Etching

Gel for 20 s

–

Conditioning Bonding surface with Monobond Plus for 60 s

Adhesive

cementation

Multilink Hybrid Abutment

Covering the cement

joint

Glycerine gel, e.g. Liquid Strip

Curing Approx. 7 min auto-polymerization

Polishing the cement

joint

Conventional polishers for ceramic/composite

resin

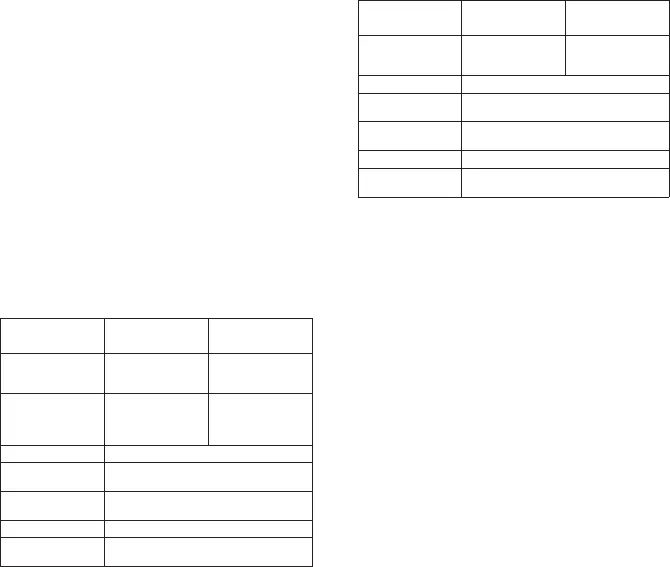

Ceramic structure

(ZrO

2

)

Base

Blasting

According to the

instructions of the

manufacturer

According to the

instructions of the

manufacturer

Conditioning Bonding surface with Monobond Plus for 60 s

Adhesive

cementation

Multilink Hybrid Abutment

Covering the cement

joint

Glycerine gel, e.g. Liquid Strip

Curing Approx. 7 min auto-polymerization

Polishing the cement

joint

Conventional polishers for ceramic/composite

resin