SafeShield Safety Light Curtain Hardware User Manual

16

Table 10. For this reason the moving area must always be

greater than the effective resolution at the edges of the

area.

If you configure a blanked area without positional and

without size tolerance, the movement of the object within

the area is very limited before the light curtain may change

to red.

The maximum selectable tolerance values depend on the

size of the blanked area: The actual tolerance expansion in

millimetres differs. It depends on the physical resolution of

the device.

Device symbol SafeShield safety light curtain Host

(receiver), context menu Configuration draft, Edit,

file card Blanking of the appropriate system, option Type

of blanking = fixed. Here you can also set the positional tolerance

and size tolerance directly in millimetres.

Increased Size Tolerance

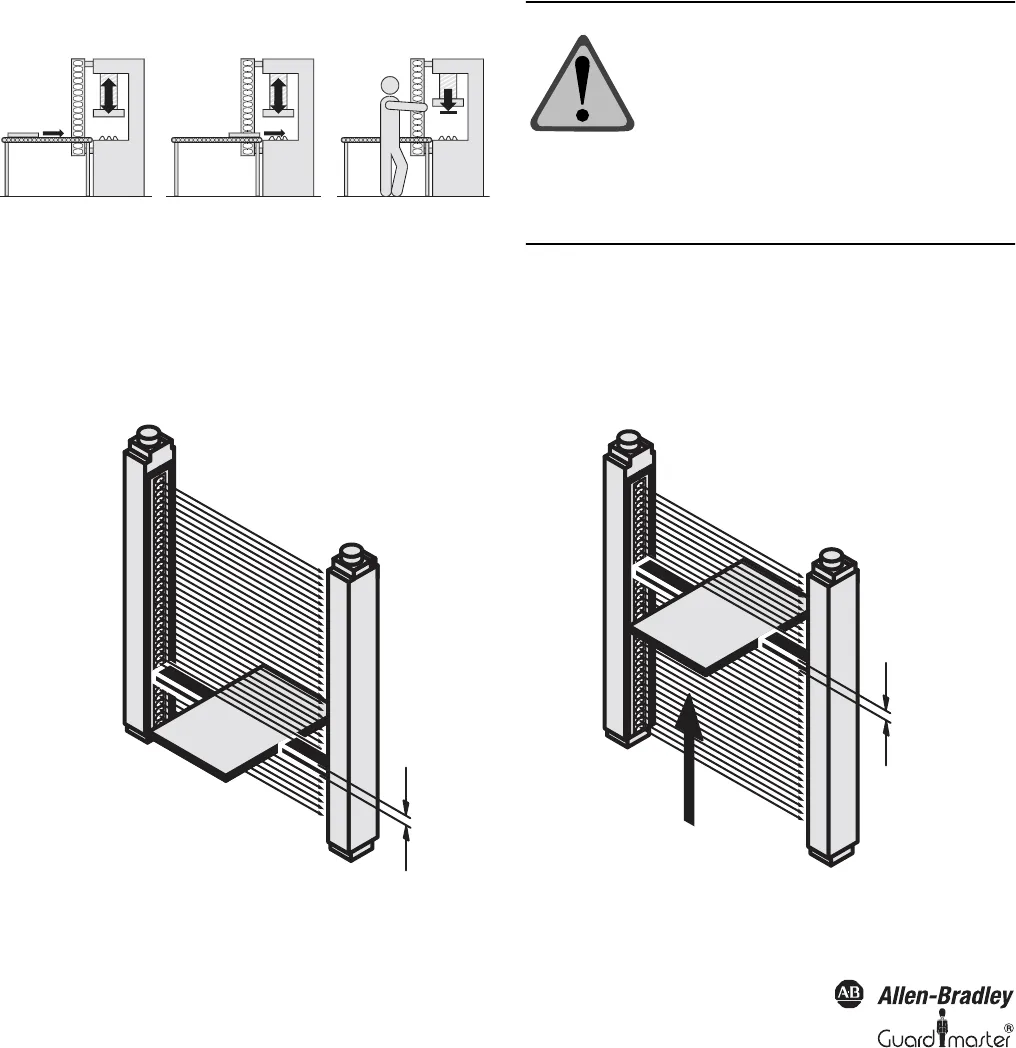

Figure 11: Schematic layout of the fixed blanking with increased size

tolerance

You can configure an increased size tolerance of the fixed blanking.

In this way objects can pass through the protective field on one side

of the fixed blanking, e.g. for material feed on a conveyor belt (➦

and ➨). Configure fixed blanking for the conveyor, for the material

input an increased size tolerance above the fixed blanking.

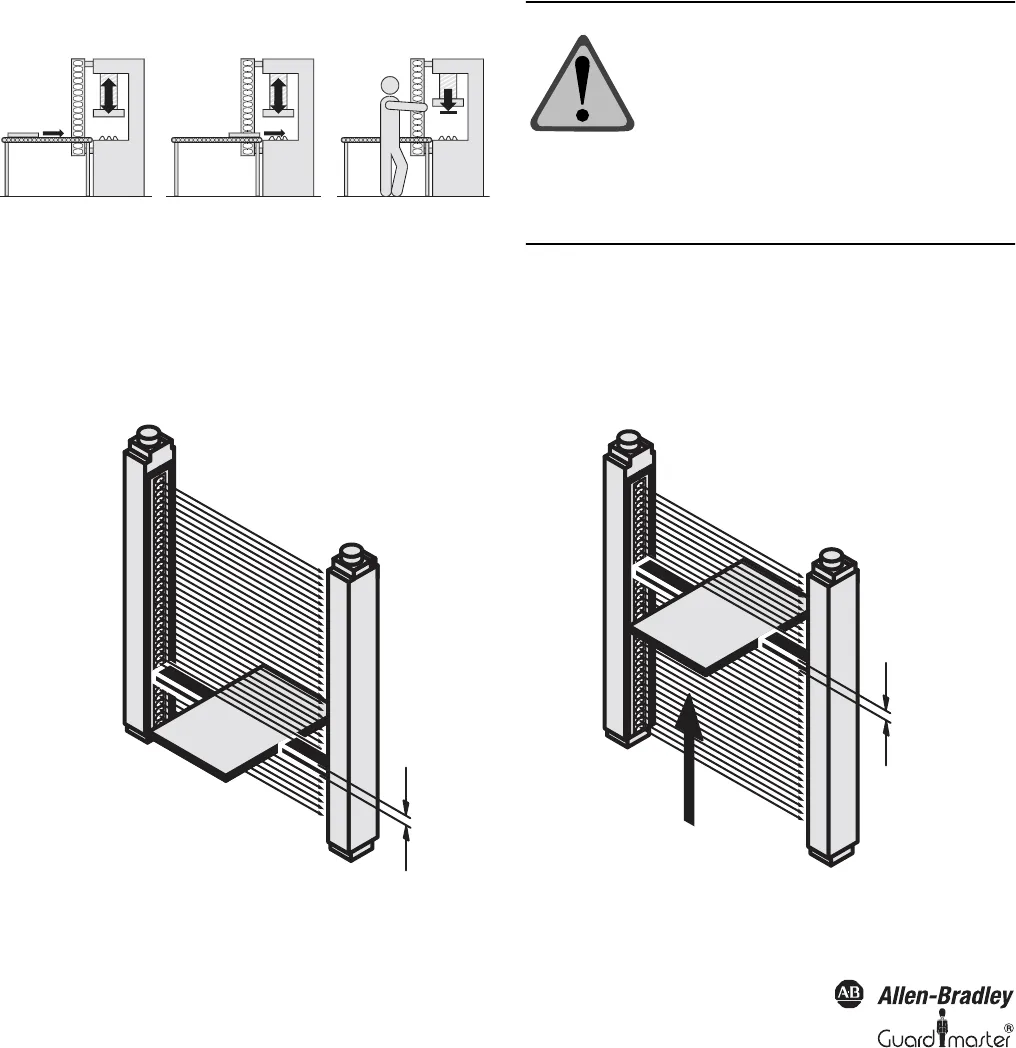

Figure 12: Example of mechanical protection of fixed or floating blanking

!

➦➨!

Blanked area, sides

protected by

mechanical barriers

Unlike the normal size tolerance for blanking, the increased size

tolerance allows the blanked object on a specific side of the area to

be larger than the blanked area.

In the area of the increased size tolerance, the object can penetrate

the protective field if it does not exceed the increased size

tolerance defined.

Notes The increased size tolerance must not cover the last

beam.

On fixed blanking with increased size tolerance, you

cannot configure a positional tolerance or a normal size

tolerance in addition.

You can expand the increased size tolerance to the next blanked

area as a maximum, or to the second or second last beam of the

light curtain.

➢ After modifying the blanking, check the protective field with the

test rod. Instructions can be found in the “Daily Functional

Checks of Protective Device” on page 31.

➢ Also pay attention to the warnings in the related chapter.

ATTENTION: Blanked areas require a

separate risk analysis!

A blanked area is in principle a hole in the

protective field. Check in detail whether and

where blanking is actually required. You must

protect the blanked area in another way, e.g.

mechanically. Otherwise you must take the

blanked area into consideration in the

calculation of the safety distance and mount

the safety light curtain appropriately.