24

tRoubleshootinG

Poor performance of the engine and/or cutting mechanism can normally be prevented by carefully following these

instructions.

Poor performance can easily be corrected even by a beginner.

When the engine does not function properly check the following three (3) points rst.

• Istheenginecompressionadequate?

• Isfuelsystemingoodconditionandisenoughfuelbeingsupplied?

• Iselectricalsystemingoodconditionandissparkplugoperatingnormally?

When there is serious trouble with the unit, do not try to repair it yourself but have your distributor or dealer do it for

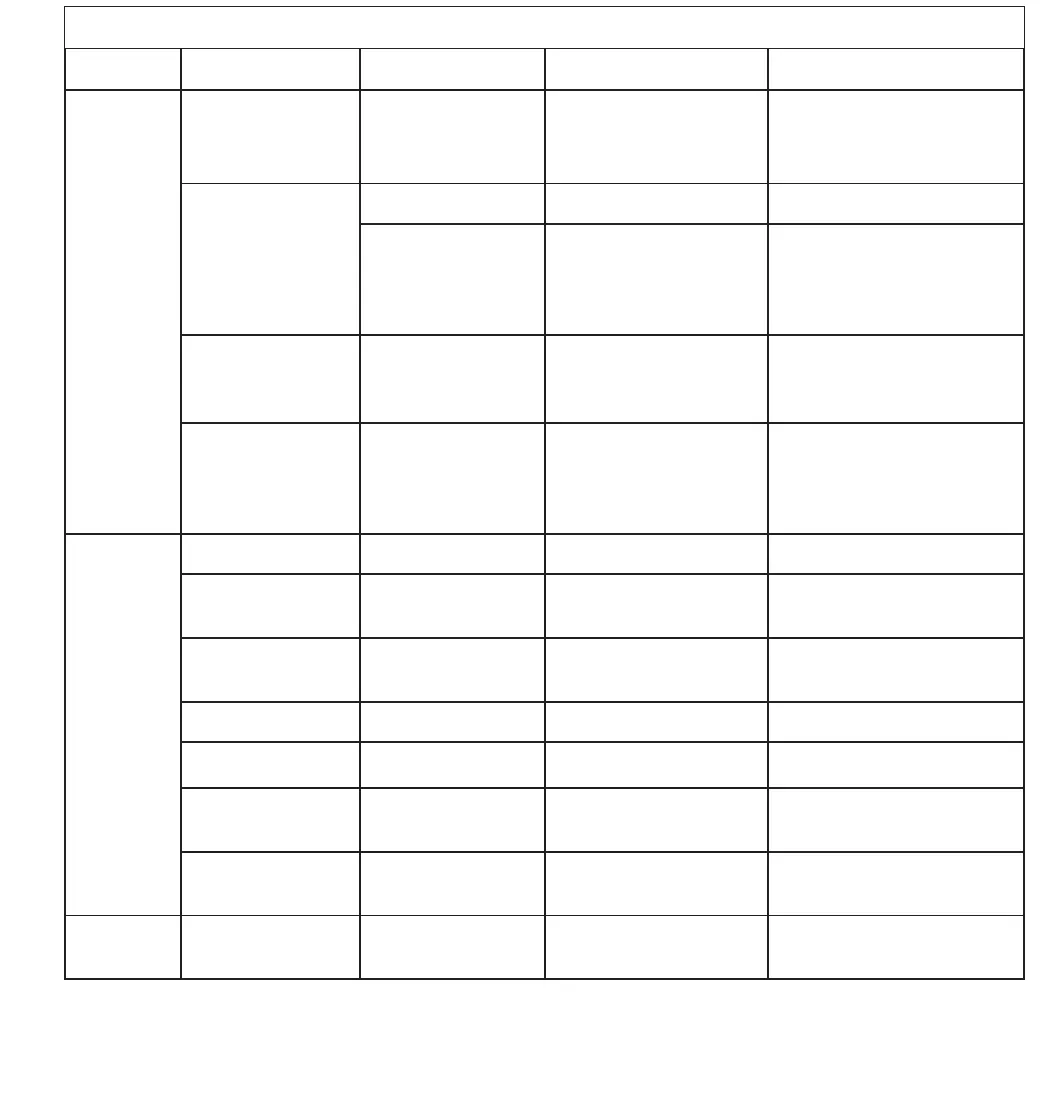

you. For detailed TROUBLESHOOTING refer to tables 1 and 2. Locate the problem on the following charts and repair

as necessary.

reaching carburetor

Fuel is not reaching

cylinder

No spark at high

tension cord end.

Engine does not start (or, is difcult to start)

Engine cranks

There is fuel in the tank

Fuel is reaching carburetor

Fuel is reaching cylinder

There is spark at high

tension cord end

There is spark at plug

Starting procedures

correct

No spark at plug

Fuel does not keep

running

Acceleration and low

speed function defective

Carburetor

overow

Engine does

not crank

Fuel strainer

clogged ..........

Clean.

Fuel pipe

clogged ............

Clean.

Suction insuf-

cient ................

Make sufcient.

Strainer clogged ..........................................Clean.

Carburetor out of order ................................Disassemble and check.

C.D.I. module defective ...............................Remove and replace.

Ignition coil defective ...................................Remove and replace.

Wire connection defective ..........................Reconnect.

High-tension cord connection defective.......Repair as necessary.

Switch is grounded ......................................Switch on.

Insulator cracked .........................................Replace plug.

Spark gap incorrect .....................................Adjust.

Covered with carbon....................................Clean or replace.

Fouled with fuel ...........................................Clean or replace.

Starting procedures incorrect ......................Start correctly.

Low and high speed needle.........................Readjust.

setting too lean

Metering lever spring too strong ..................Readjust.

Fuel pump diaphragm defective ..................Replace.

Fuel passage clogged with dust ..................Disassemble and clean.

Fuel leaking from xing surfaces ................Retighten all screws.

of carburetor

Table 1

Fuel is not

Air valve, fuel tank cap does not

work normally ..............................................Replace or Clean.

Fuel pump does not operate........................Check

impulse drilling.

Fuel inlet needle valve clogged with dust ....Clean.

Metering lever spring not placed

in dent of lever .............................................Correct.

Mufer sticky with fuel .................................Fuel mixture is too rich

Start the engine several

times

with choke rod fully open

and

run at fast idle until engine

does not smoke.

Bearing damaged ........................................Disassemble and

replace.

Piston and/or cylinder seized.......................Disassemble and replace.

Crankshaft worn ..........................................Disassemble and replace.

Crankshaft contacting crankcase ................Disassemble and replace.

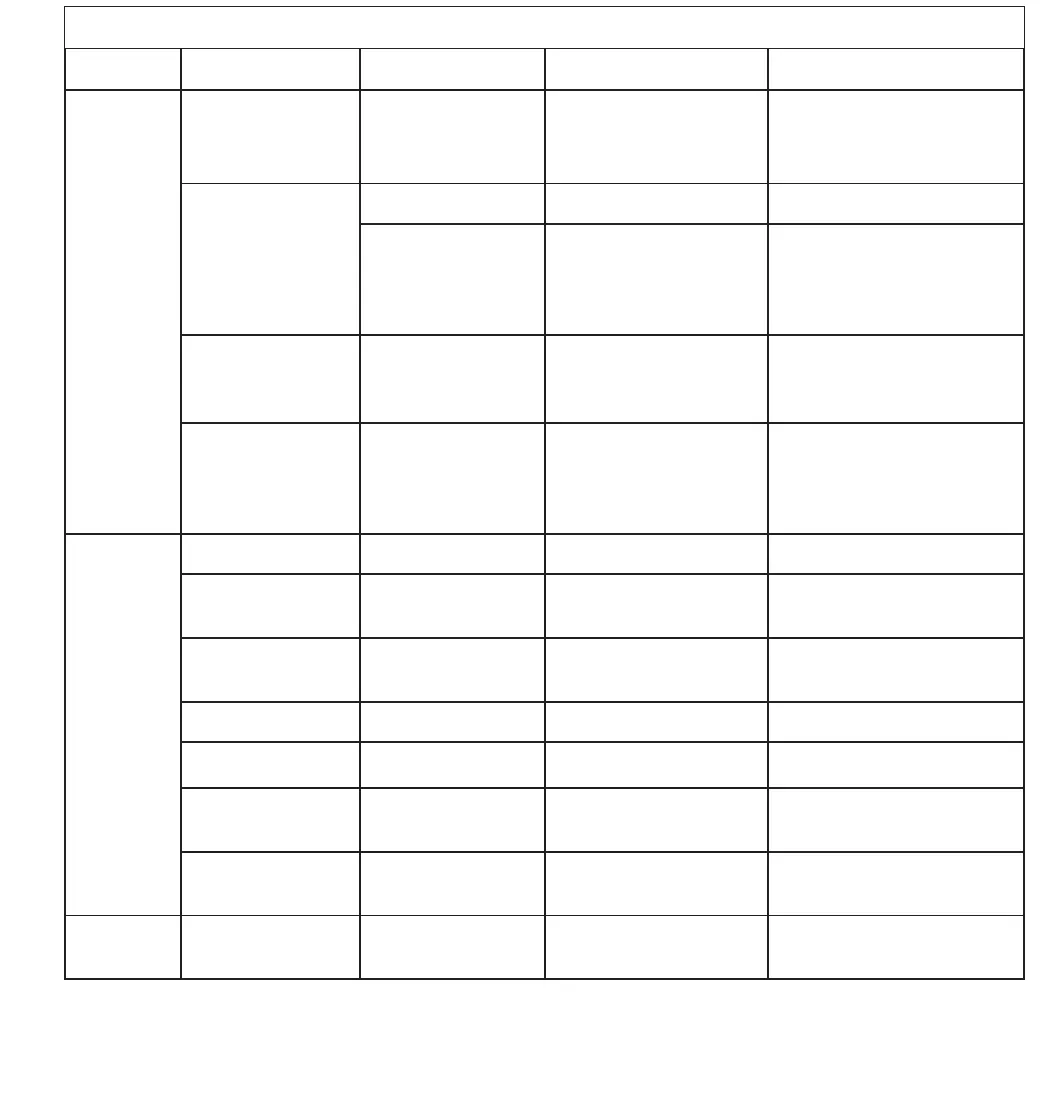

TRAHCGNITOOHSELBUORTMELBORPENIGNE

melborPkcehCsutatSesuaCydemeR

enignE

-sknarc

/drahstrats

t'nseod

trats

roterubractaleuFroterubractaleufoNdeggolcreniartsleuF

deggolcenilleuF

roterubraC

ecalperronaelC

ecalperronaelC

relaedohcEruoyeeS

rednilyctaleuFrednilyctaleufoNroterubraCrelaedohcEruoyeeS

leufhtiwtewrelffuMhcirooterutxiMleuFekohcnepO

retlifriaecalper/naelC

roterubractsujdA

relaedohcEruoyeeS

dnetakrapS

eriwgulpfo

krapsoNffohcti

wspotS

melborplacirtcelE

hctiwskcolretnI

NOothctiwsnruT

relaedohcEruoyeeS

relaedohcEruoyeeS

gulptakrapSkrapsoNtcerrocnipagkrapS

nobrachtiwderevoC

leufhtiwdeluoF

evitcefedgulP

).ni620.0(mm56.ottsujdA

ecalperronaelC

ecalperronaelC

gulpecalpeR

,snurenignE

roseidtub

tonseod

etarelecca

ylreporp

retlifriAytridretlifriAraewlamroNecalperronaelC

retlifleuFytridretlifleuFseudiser/stnanimatnoCni

leuf

ecalpeR

tnevleuFdeggulptnevleuFniseudise

r/stnanimatnoC

leuf

ecalperronaelC

gulPkrapSnrow/ytridgulPraewlamroNecalperrotsujdadnanaelC

roterubraCtnemtsujdareporpmInoitarbiVtsujdA

metsySgnilooCmetsysgnilooC

deggulp/ytrid

ninoitarepodednetxE

snoitacolytsud/ytrid

naelC

rotserrAkrapS

neercS

rotserrakrapS

deggulpneercs

raewlamroNecalpeR

seodenignE

knarcton

A/NA/NmelborpenignelanretnIrelaedohcEruoyeeS