Technical data

Dimensions, mm 34 1/4" X 23 1/2" X

23 1/2"

Weight 170 lbs

Spin speed 800/1000 r/min

Rated load 3505 W/240 V

3240 W/230 V

Supply voltage 208-240 V, 60 Hz

single-phase

Heater rating 3265W/240V

3000 W/230 V

Material of drum

and barrel

Stainless steel

Material of

outer casing

Stove-enamelled

hot-dip-galvanised

steel sheet

Mounting

Stationary: four

adjustable rubber-

covered feet

Water suppiy

hose

5 ft pex hose

Supply pressure 0.1-1 MPa

(10-100 N/cm*,

1-10 kp/cm*,

15-146 PSI)

Outlet 5.5 ftof poly-

propene hose,

3/4" internal

diameter

Accessories

The machine is supplied with:

• Operating instructions and

installation instructions.

• Guarantee card.

• Type-approved inlet hose for

connection to water supply.

Optional extras:

• Decor frames

• Edging frame by stacked

machines

• Frame set with pull-out shelf by

stacked machines.

Installation Instructions

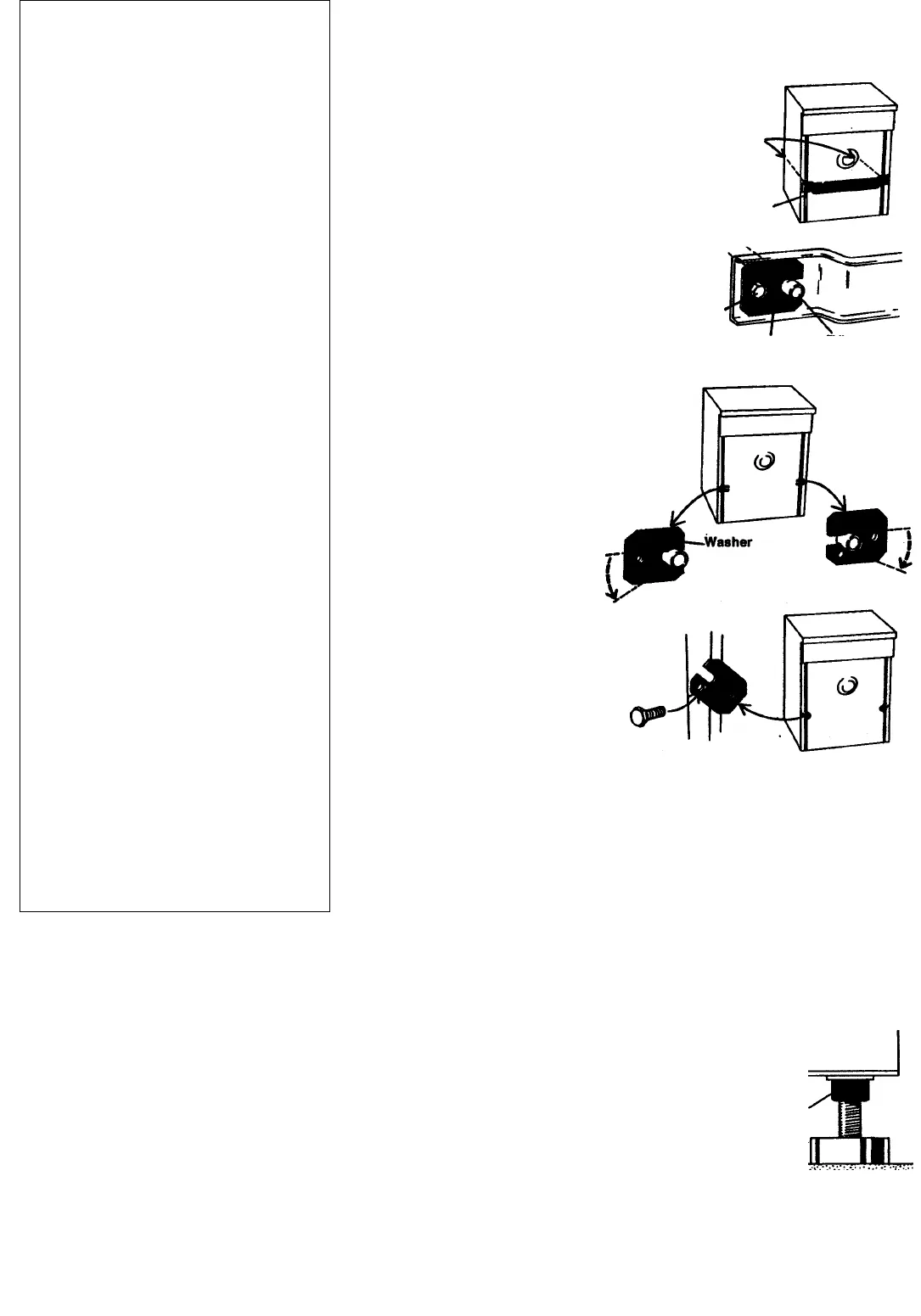

Removing the shipping brace

The shipping brace consists of two tubes

which prevent the barrel from moving

around inside the machine during

transport. The tubes are secured to a

cross beam at the back of the machine.

Remove the shipping brace as follows:

1. Remove the bolts and special

washers which retain the beam,

and remove the beam.

Two tubes

inside

the machine

Cross beam

Boit

Washer

Tube

2. Replace the washers on the flattened

part of the tubes. Use them as tools

to turn the tubes through about 45°,

as shown in the drawing, and pull out

the tubes.

3. Turn the washers so that

they cover the holes

where the tubes were

fitted and replace the

bolts.

Save the tubes and cross beam,

which will be needed if the machine

has to be transported elsewhere.

Fit them in the reverse order to that

described above.

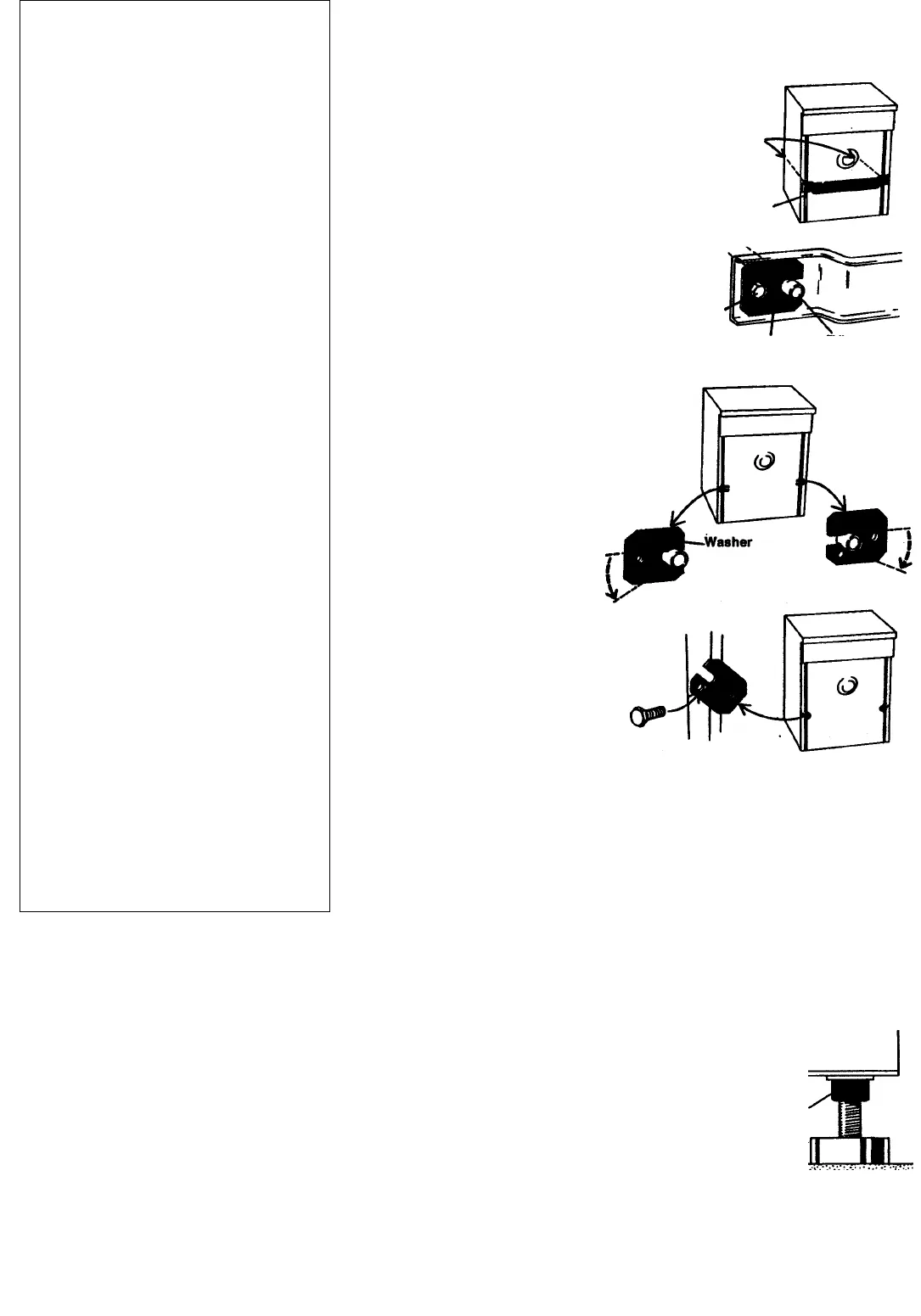

Adjusting the feet

It is important that the machine

does not move around when it is

spinning. This means that it must

be standing firmly and level on the

floor. The four feet are individually

adjustable. Set them carefully so

that the machine is standing level,

and tighten the locknuts securely.

Positioning the machine

The machine can be installed beneath a

worktop with a height of 33 1/2"-35 1/2".

There must be a gap of about 1/4" all round

the machine, including between the rear ^

edge of the machine top panel and the wall

behind. This is important: if no space is left,

the machine may hit the wall when it starts

to spin.

Lock nut

NOTE

Height adjustment: 32 1/4"-33 1/2'

Do noty raise Higher than 33 1/2*

10