041-028-B1-001 Rev. B (09/2012)2

Total Power Solutions

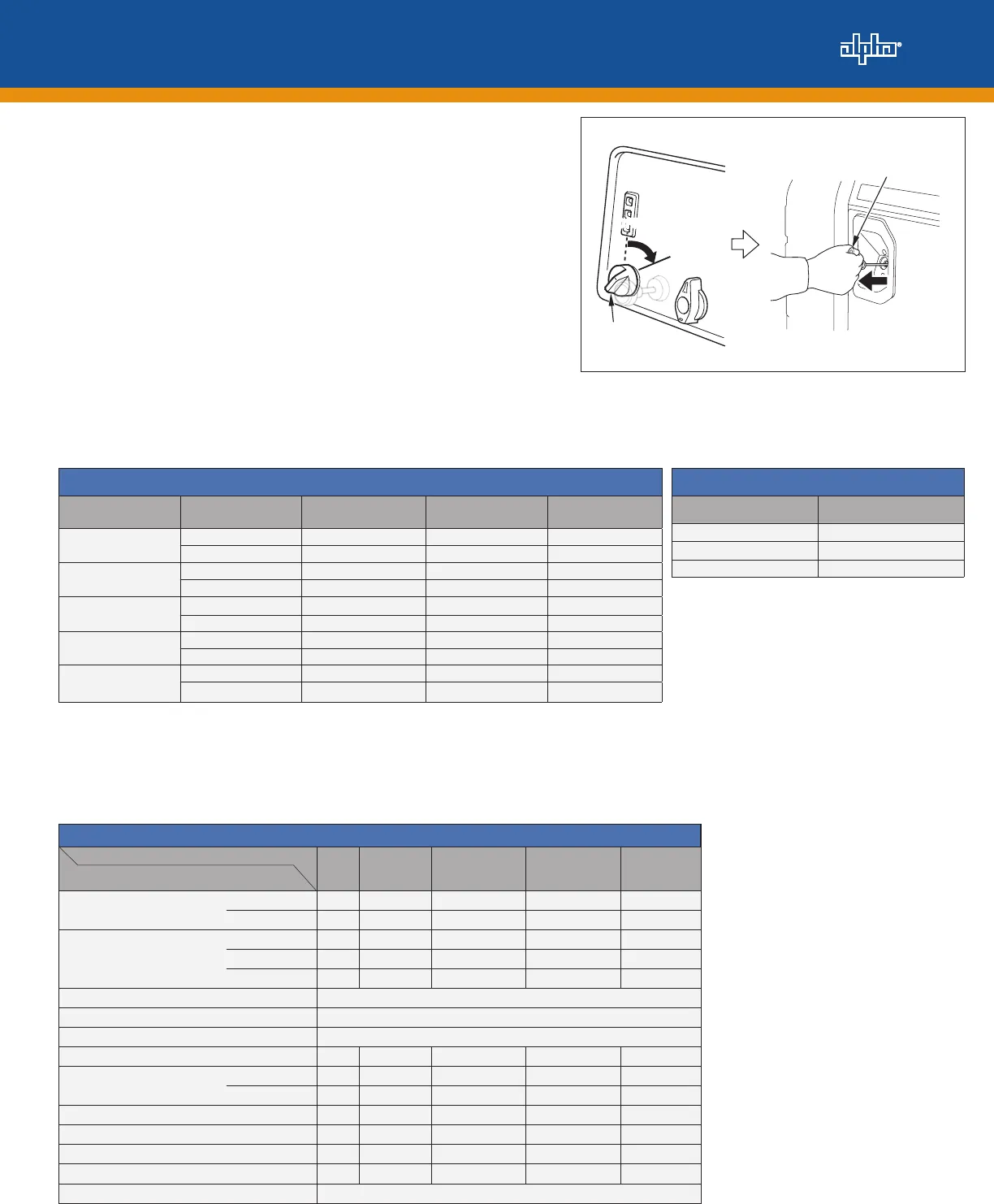

3. Turn the Engine Switch to the ON position (see Figure 2-2).

4. Pull the Starter Grip until you feel resistance, then pull

strongly in a straight line (see Figure 2-2).

Note: Pulling the Starter Grip at sharp angle to the

engine will prematurely wear out the cord. Do NOT let

the starter grip snap back against the engine.

5. If the choke was CLOSED to start the engine, gradually

push the choke in to the OPEN position as the engine

warms up.

Note: When the engine starts, DC output will begin

charging the UPS battery string automatically and the

output indicator (green) will go ON. If the UPS battery

string voltage is too low, the DC output will turn off. At

this time, the output indicator (green) will go OFF and

the overload indicator (red) will go ON (see Table 2-1).

Figure 2-2, Engine Switch and Starter Grip operation.

DC Output Coupler

Power

Coupler

DC Voltage

Selector

Switch

Voltmeter

Maintenance

Cover

No gap

Choke

Knob

Choke

Knob

CLOSED

O

OPPEENN

Choke

Knob

CLOSED

OPE N

Fuel Valve

Lever

ON

O

OFF

Engine

Switch

O

OFFFF

O

ONN

Starter Grip

Direction

to pull

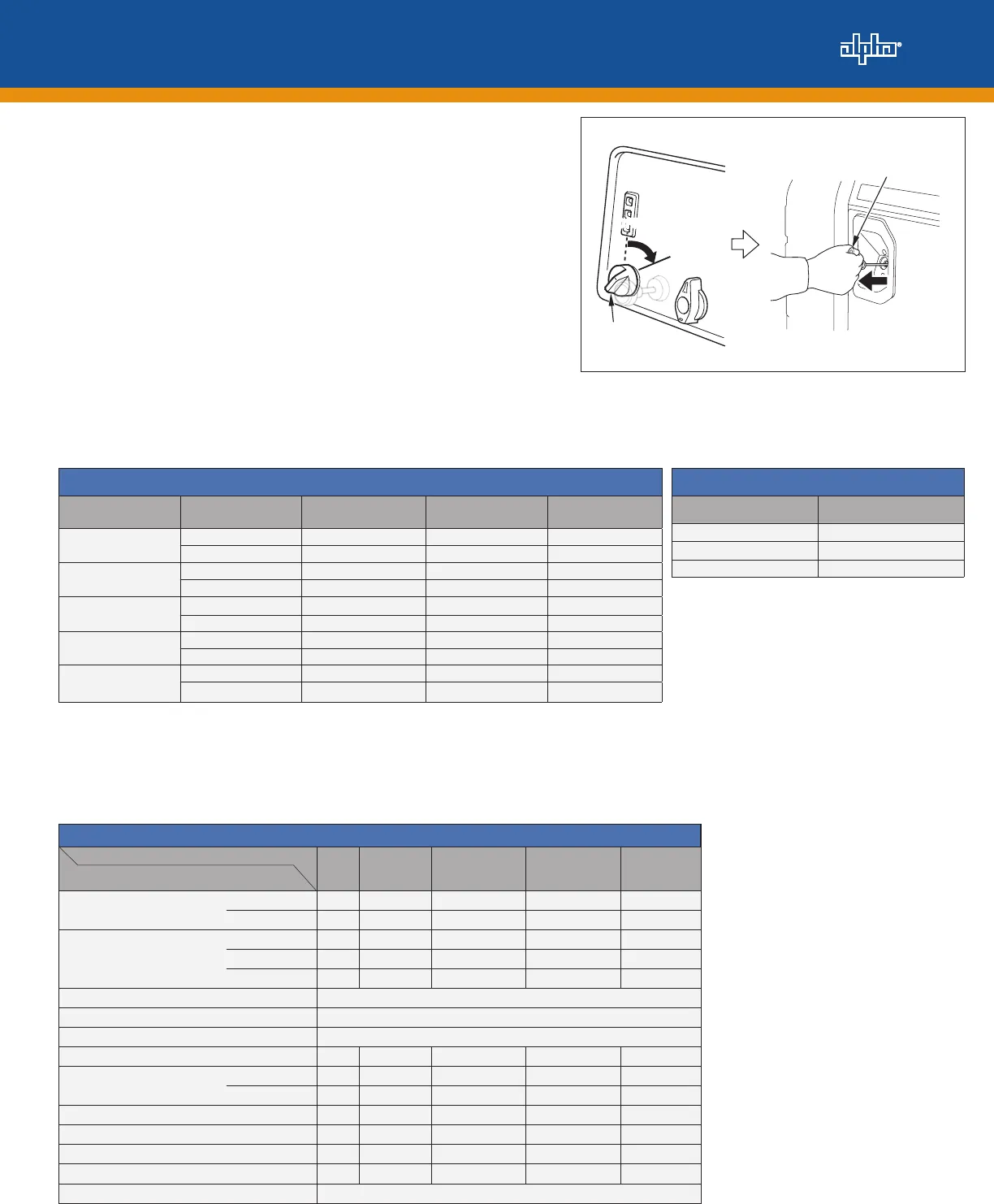

Table 2-1, Battery Voltage alarm indicators.

Battery Voltage Alarm Indicators

Battery Voltage

1

Voltage Select

Switch Position

Output Indicator

(Green LED)

Overload Alarm

(Red LED)

Forced Output

2

0V to 2V

36V OFF OFF Not Available

48V OFF OFF Not Available

2V to 27V

36V OFF FLASHING ENABLED

48V OFF FLASHING ENABLED

27V to 42V

36V ON OFF Not Available

48V OFF FLASHING ENABLED

42V to 55V

36V OFF FLASHING Not Available

48V ON OFF Not Available

>56V

36V OFF FLASHING Not Available

3

48V OFF FLASHING Not Available

3

Run Time Table

Load Run Time (Hours)

25% 20

80% 10

100% 7.2

Table 2-2, Load to approximate run time.

(1)–All battery voltage measurements are ± 1V.

(2)–To enable forced output when the Overload Alarm LED is ashing, press the output button for at least 5 seconds. The Overload Alarm

LED stops ashing. Release the output button, and then press it again for at least ve seconds. The Output Indicator LED turns on steady,

and power output begins. The operator may then release the output button.

(3)–Engine shuts down after 1 second.

3.0 Maintenance Schedule

MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD

Note: Perform at every indicated month or oper-

ating hour interval, whichever comes rst.

Each

use

First month

or 20 hrs.

Every 3 months

or 50 hrs.

Every 6 months

or 100 hrs.

Every year or

300 hrs.

Engine Oil Check Level O

Change O O

Air Cleaner Check O

Clean O

2

Replace O

1

Canister Check Every 2 years (Replace if necessary)

3

Purge tube Check Every 2 years (Replace if necessary)

3

Charge tube Check Every 2 years (Replace if necessary)

3

Sediment Cup Check O

Spark Plug Check-adjust O

Replace O

Spark Arrester Clean O

Valve Clearance Check-adjust O

3

Combustion chamber Clean

Fuel tank and lter Clean O

3

Fuel tube Check Every 2 years (Replace if necessary)

2

(1)–Replace the paper air lter element only.

(2)–Service more frequently when used in dusty areas.

(3)–These items should be serviced by an authorized

AlphaGen dealer.

For commercial use, log hours of operation to

determine proper maintenance intervals. Failure to

follow this maintenance schedule could result in non-

warrantable damage.

Table 2-3, Battery Voltage alarm indicators.