MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 5

8

EVERY 250 HOURS OR EVERY 6 MONTHS

E.g. to adjust valves and bridge pieces on

No. A1 cylinder set No. A6 cylinder valves

rocking for the 4012 engine and No. A8 for

the 4016 engine.

RESETTING THE VALVE CLEARANCES

WITH ENGINE COLD

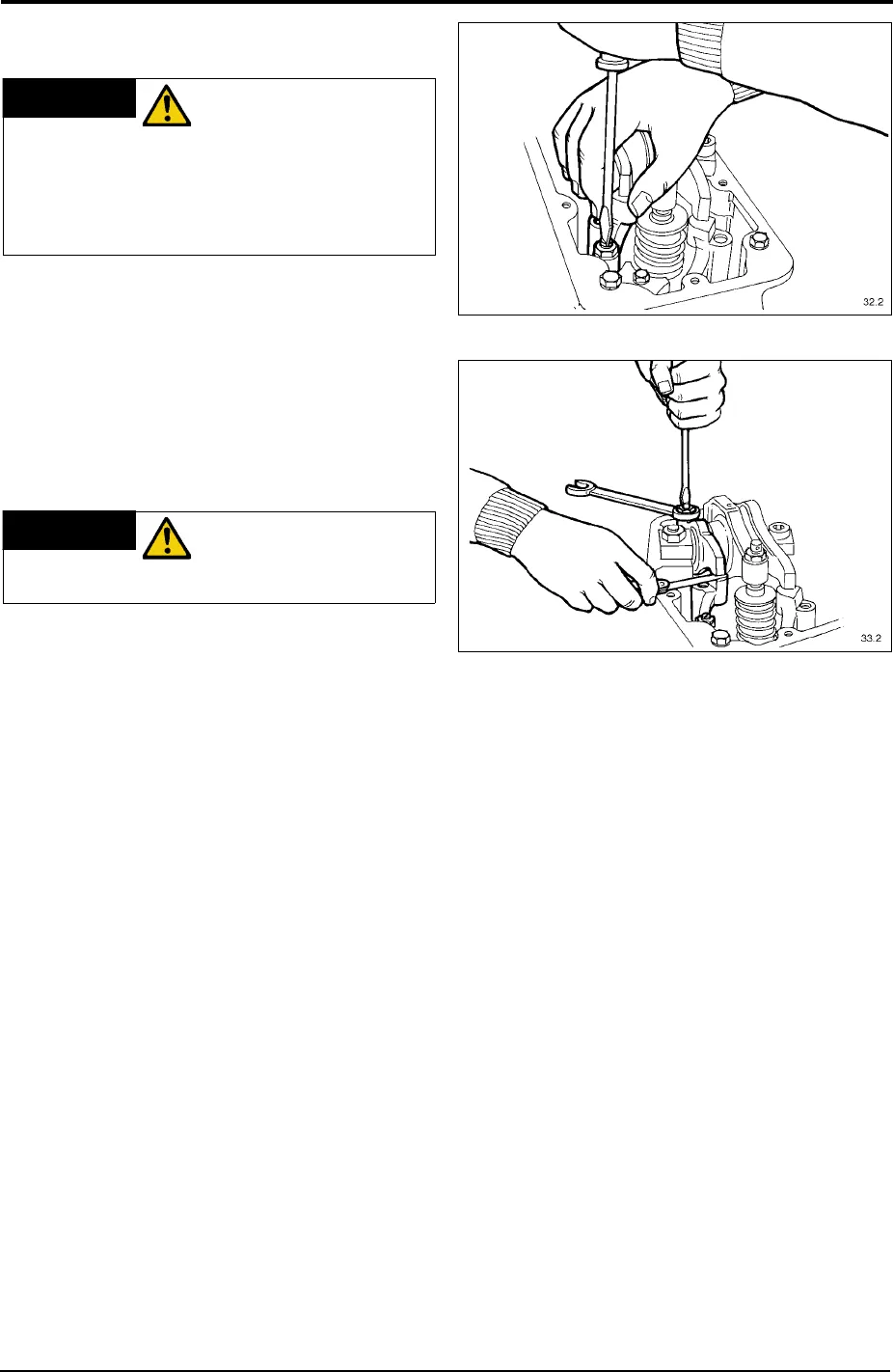

With both bridge pieces equalised, check

and adjust the valve clearance using a 0.4

mm (0.016") feeler gauge for both the

exhaust and inlet valve set between each

rocker and bridge piece Fig. 53. If required

screw the adjuster until the rocker is bearing

lightly on the feeler gauge. Tighten the lock

nut without moving the adjuster. (See

Torque Settings page 16). The feeler

g

auge should be a slide fit between the

rocker and bridge piece, thereby giving the

correct clearance. Refit the rocker cover

with a new gasket.

For further instructions on maintenance

please refer to the Maintenance Section of

t

he Workshop Manual

.

L

INKAGE FROM THE GOVERNOR TO

THE CONTROL SHAFTS

Check the freedom of operation of these

important linkages, which are vital to the

proper running of the engine.

WARNING

FAILURE TO

EQUALISE A BRIDGE

PIECE MAY RESULT IN ENGINE

DAMAGE. ALWAYS CHECK THAT THE

PARTS FIT TOGETHER AND MOVE

FREELY, BEFORE ASSEMBLY.

WARNING

DISCONNECT THE

BATTERIES AND ALL

OTHER MEANS OF STARTING ENGINE.

Fig. 52

Fig. 53