MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 5

4

EVERY 250 HOURS OR EVERY 6 MONTHS

CHANGING THE CHANGE OVER FUEL

FILTER ELEMENTS WHEN THE ENGINE

IS STOPPED

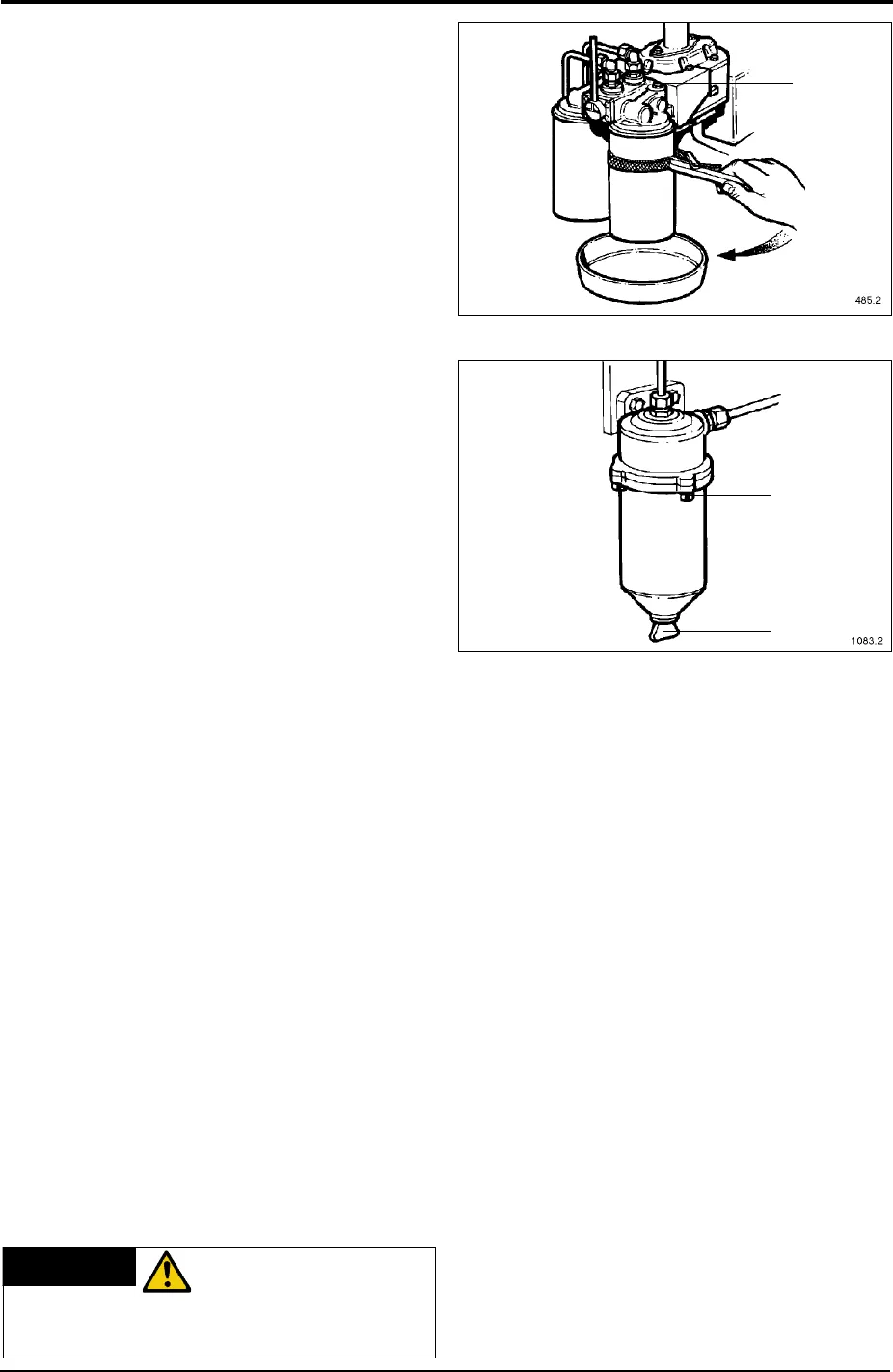

All that is necessary is to unscrew the

canisters with a strap wrench as shown in

Fig. 48, leaving the change-over lever in the

vertical position as there is no pressure in the

fuel system with the engine stationary. The

replacement canisters are screwed on by

hand, after applying a smear of clean engine

oil to the rubber seals, and tightening by firm

hand pressure only. Bleed the air from the

new filters by slackening the vent screws

and operating the priming pump. Check for

leaks when the engine is restarted.

CHANGING THE CHANGE OVER FUEL

FILTER ELEMENTS WHEN THE ENGINE

IS RUNNING

The normal position of the change-over

valve lever is vertically upwards, when both

filters are in circuit. Turning the lever to the

left, puts the right hand filter out of service,

so that the right hand canister may be

exchanged for a new one, smearing the seal

with clean engine oil and tightening by firm

hand pressure only. Bleed the air from the

new filter by means of the vent screw as the

lever is returned to the vertical position.

Turning the lever so that it points the right,

puts the left hand filter out of service so that

it can then be exchanged for a new one, as

before. Again bleed the air from the new filter

as the lever is returned to its normal vertical

position, so that both elements are back in

circuit, and check for leaks before leaving

the engine.

NOTE: Prepare for some spillage of fuel by

placing a bowl of about 5 litres or 1 gallon

capacity under the filter when changing the

capacities.

CLEANING WATER TRAP/SEDIMENTER

(WHERE FITTED)

Open drain plug (1) to remove collected

water and sediment. The plug is self

retaining, leave open until clean fuel is seen

then screw back in see page 41. Remove

t

he bowl by unscrewing three screws (2).

Clean thoroughly all components and dry

with compressed air. Replace joint washer if

damaged.

FUEL SUPPLY AND PRIMING CIRCUITS

MAINTENANCE INSTRUCTIONS

FUEL LIFT PUMP

For information on the lift pump see Section

K

K1 of the Workshop Manual

.

HAND PRIMING PUMP (OPTIONAL)

The pump requires no maintenance but

should it fail to operate a replacement unit is

required.

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING.

ALWAYS WEAR PROTECTIVE GLOVES.

Fig. 48

1

Fig. 48.1

2

1