MAINTENANCE SCHEDULE & CHECKLISTS

4012/16 Diesel, February 1997 5

0

EVERY 250 HOURS OR EVERY 6 MONTHS

CHANGING ENGINE OIL AND OIL FILTERS

(STANDARD HORIZONTAL TYPE)

With the engine stopped, place a suitable

container of at least 214 litres (47 gal)

beneath the drain plug (which is situated on

the bottom edge of the sump directly under

the dipstick). Remove the drain plug and

allow the oil to drain. This operation is best

carried out while the engine is still warm as

the thinner oil will drain more quickly. While

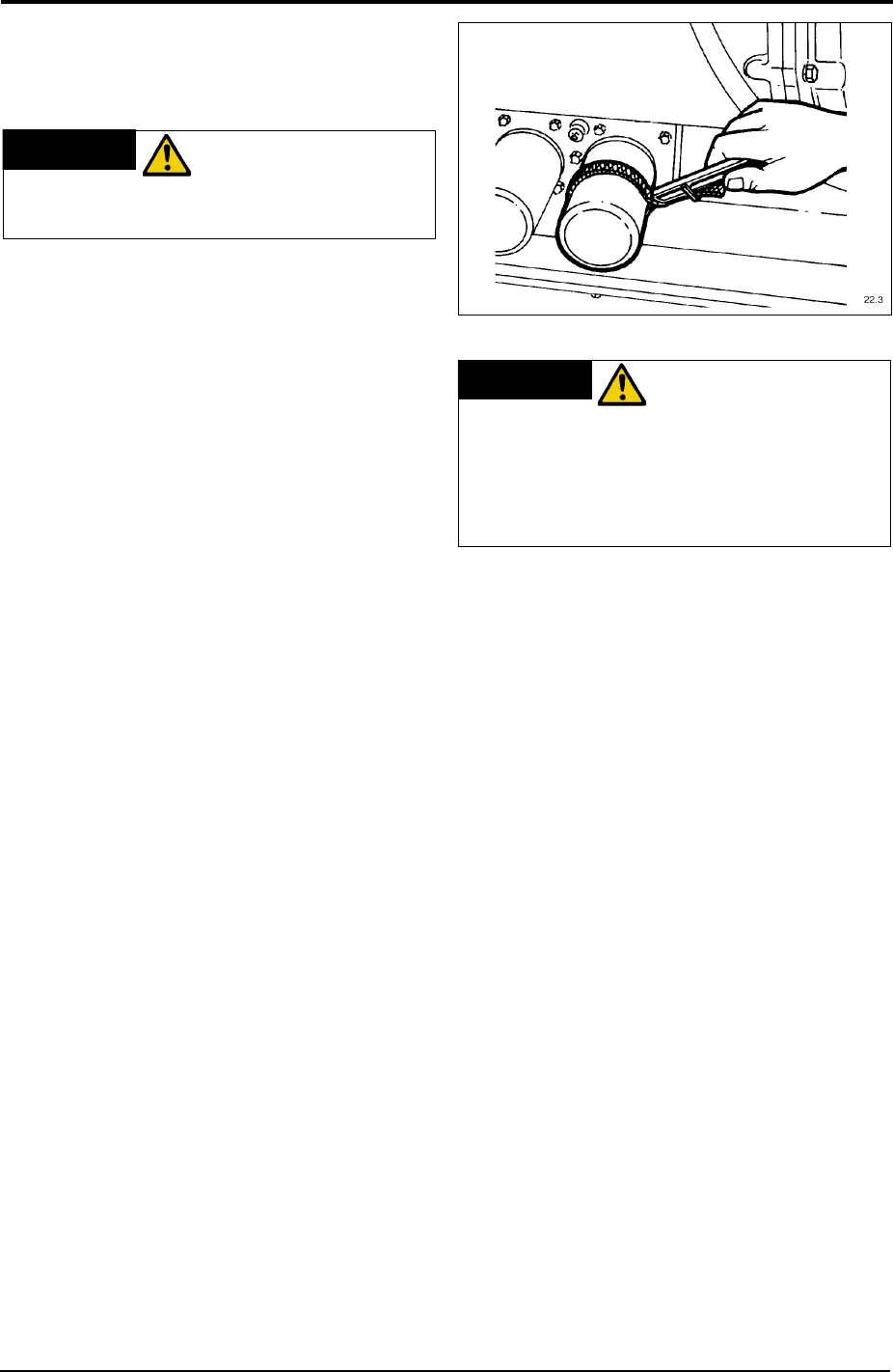

the oil is draining remove all three oil filters

per bank, two on the main header supplying

the bearings and one on the single header

supplying the piston jets, by turning them

anti-clockwise with a strap wrench Fig. 43).

NOTE: Removal of the oil filters will allow

an escape of oil from the filter headers. It is

therefore recommended that a suitable

container of at least 5 litres (1 gal) capacity is

positioned under each header prior to filter

removal as the oil filters are of the disposable

canister type they must be thrown away. Fill

the oil filters with clean engine oil prior to

fitting. Wipe clean the sealing faces and

threaded bosses of the header. Smear

engine oil on the captive rubber sealing ring

and carefully screw each new filter up to the

oil header using firm hand pressure only.

Having drained the engine oil, refit the drain

plug and fill the engine with the appropriate

grade of new oil (see pages 19 & 2 0).

E

nsure that the switch on the control panel

and fuel stop lever on the engine are both in

their respective 'stop' positions, and that the

air shut-off valves have been manually set to

the 'run' position (see

Fig. 2). Then motor

t

he engine over on the starter until a

pressure of approximately 40 kPa (5lb/in2) is

indicated on the pressure gauge, thus

ensuring that the oil filters are full and the

turbocharger bearings are primed (see page

23

). Check the dipstick and add more oil if

n

ecessary.

CHANGING THE OPTIONAL CHANGE-

OVER LUBRICATING OIL FILTERS

These special duplex filters are normally

intended for use on long running engines, or

where a servicing requirement may occur

when it is impossible to stop the engine to

change the filters. For this reason they are

fitted with a three way change over valve in

the head, which enables the elements to be

changed, one at a time whilst the engine

continues to run. They are normally mounted

on the engine, but they may also be remotely

mounted and connected to the engine by

means of flexible pipes.

NOTE: If the flexible connections to the filter

are removed for any reason, it is essential

that they are reconnected correctly to avoid

unfiltered oil getting into the engine. See Fig.

4

4. Failure to change filters when due can

also lead to trouble from unfiltered oil.

Always fill a replacement filter with clean

engine oil before fitting.

WARNING

DISCONNECT

BATTERIES OR ANY

OTHER MEANS OF STARTING. WEAR

PROTECTIVE GLOVES.

Fig. 43

WARNING

IT IS ESSENTIAL TO

PRIME THE SYSTEM

AFTER AN OIL AND FILTER CHANGE TO

AVOID OIL STARVATION PROBLEMS,

WITH AUTOMATICALLY STARTING

GENERATOR SETS, WHICH TAKE FULL

LOAD IMMEDIATELY AFTER STARTING.