OPERATING INSTRUCTIONS

24 4

012/16 Diesel, February 1997

For earlier engines not fitted with a stop

lever, disconnect the battery leads and

remove the electric plug from the governor

by unscrewing the locking collar and pulling

the plug out of its socket. (See Fig. 2 & Fig.

3

).

O

perate the starting control or key switch

and motor the engine over on the starter until

an oil pressure of approximately 40 kPa (5 lb/

in

²

) is indicated on the pressure gauge.

Continue for a further 10 seconds to ensure

that the oil has reached the turbochargers,

and stop the engine by releasing the start

control. Disconnect the battery leads and

reconnect the electric plug in the actuator.

Reconnect the battery leads.

PRIMING THE TURBOCHARGERS ON

ENGINES FITTED WITH REGULATEURS

EUROPA OR HYDRAULIC GOVERNORS

Let the engine run without load for about 5

minutes ensuring the lubricating oil has

reached the turbochargers.

PRIMING THE TURBOCHARGERS ON

ENGINES FITTED WITH A WOODWARD

TYPE UG10 OR 3161 HYDRAULIC

GOVERNOR

NOTE: It is recommended that for initial

starting of new or overhauled engines, that

the load is disengaged, with the governor

speed control lever in the minimum speed

position, the shutdown solenoid in the STOP

position and the air shut-off valves manually

set to the run position (see Fig. 4 and

Fig.

1

1

).

Check the oil level by means of the sight

gauge. If necessary, add new SAE 30 or

SAE15W/40 engine oil (after lifting the filler

cap) to bring the oil up to the correct level

(see Fig. 2). Ensure that the fuel supply to

t

he engine is turned off.

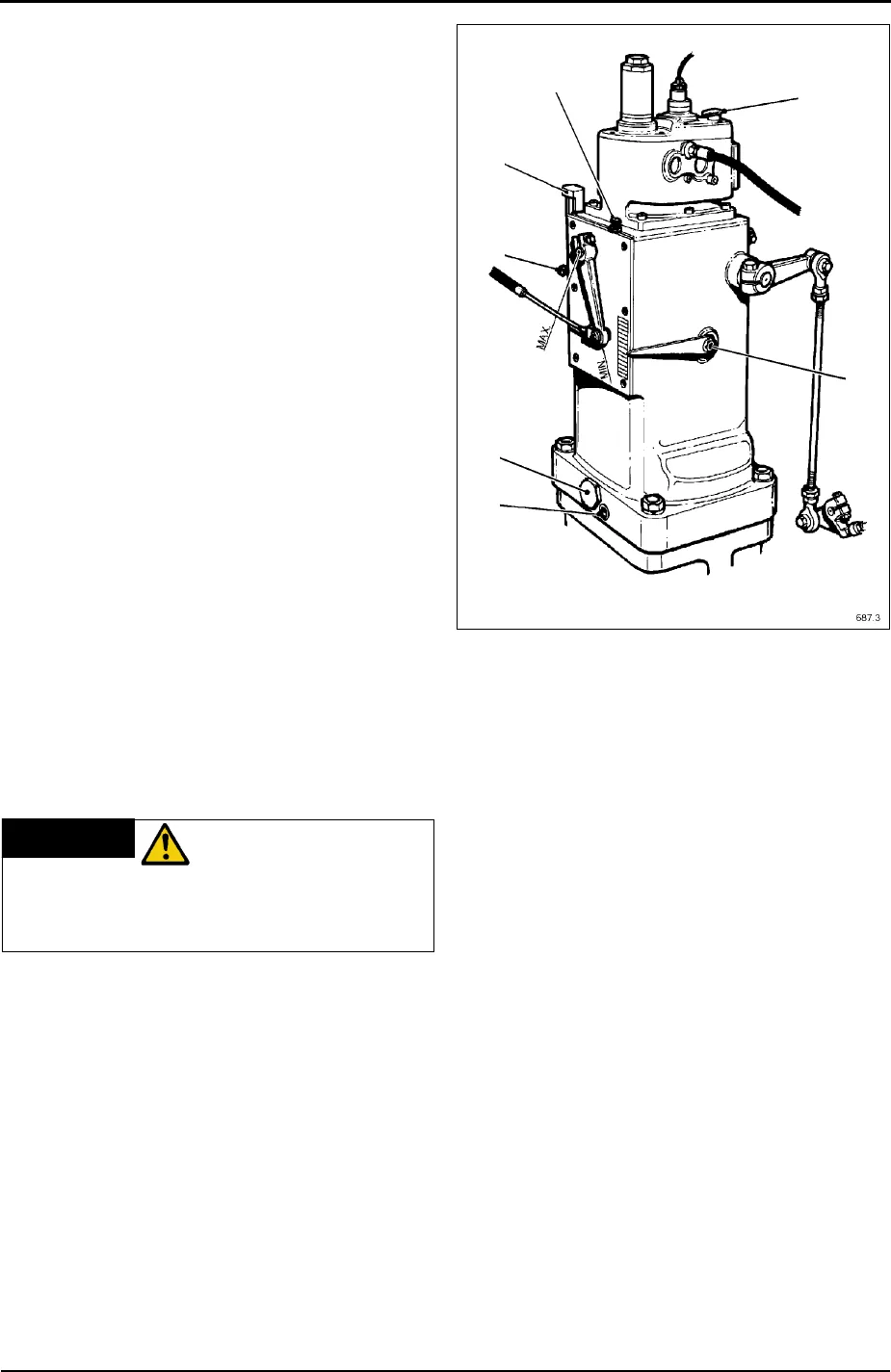

Key

(Fig. 4)

1 Low speed stop

2 Oil filler

3 Compensation adjustment

4 Oil drain plug

5 Compensating needle valve

6 High speed stop

7 Oil level gauge

With the speed control unit set in the idling

position, (for generator duty the governor

minimum and maximum speed stops are

factory set) ensure that the governor speed

lever is in the minimum speed position. Turn

the key in the instrument panel from the stop

position to the start position and motor the

engine over on the starter until the oil

pressure gauge registers approximately 40

kPa (5 lb/in

²

). Continue cranking for a further

10 seconds to ensure that the oil has

reached the turbochargers.

WARNING

THE OPERATOR

MUST BE IN A TO

PRESS THE EMERGENCY STOP

BUTTON IN THE EVENT OF A

PROTECTION EQUIPMENT FAILURE.

Fig. 4

1

2

3

4

5

6

7