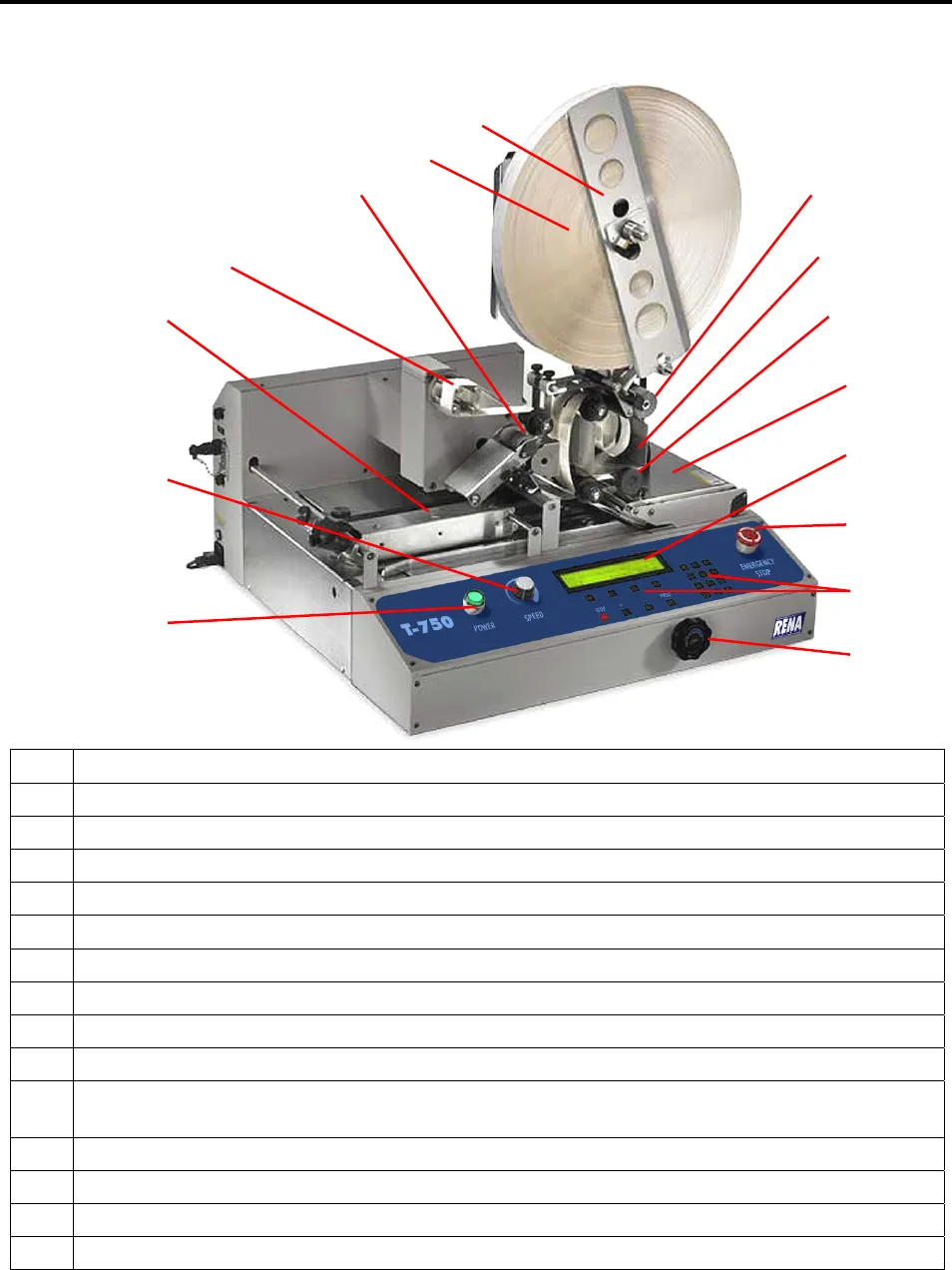

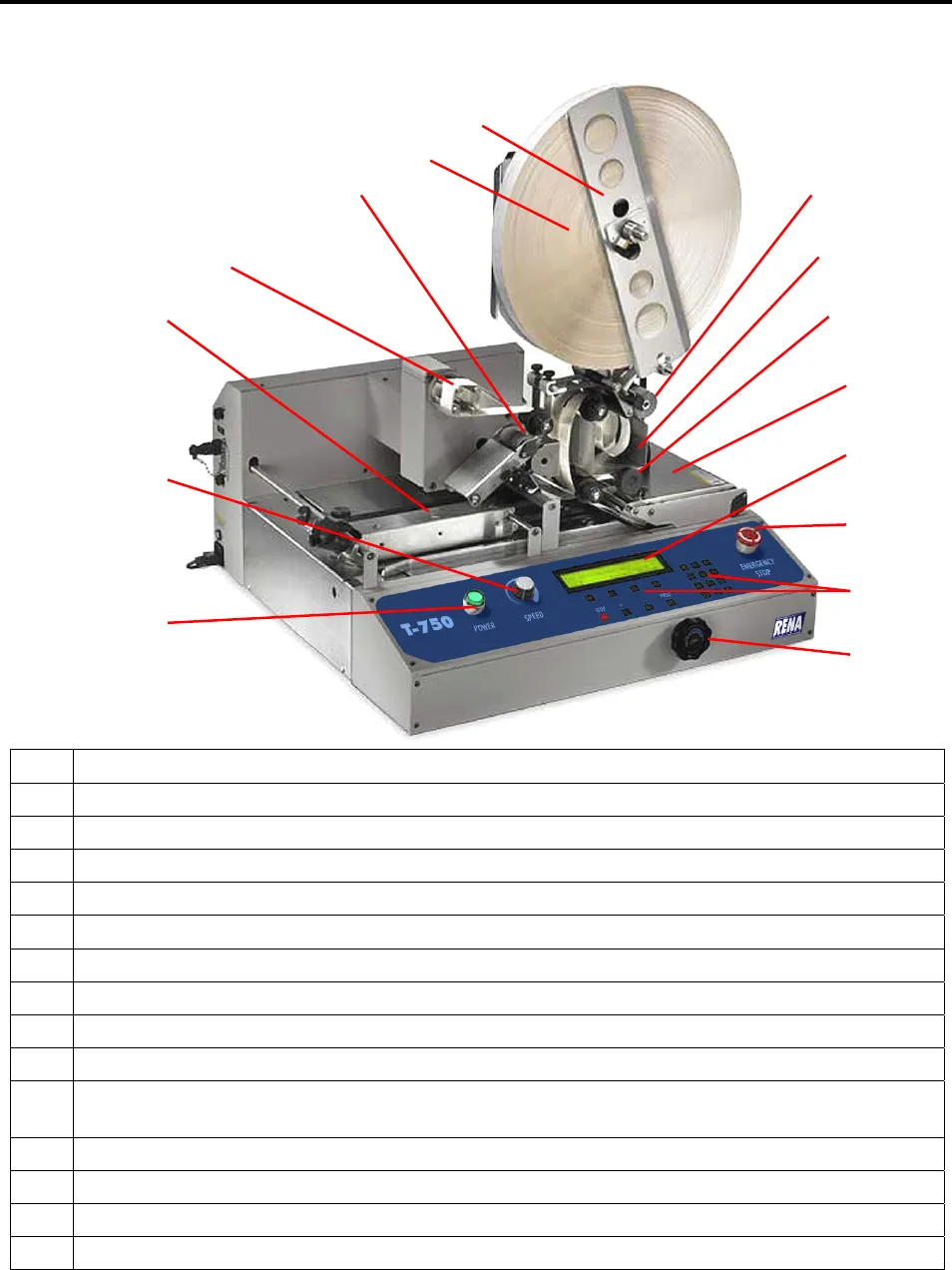

GETTING ACQUAINTED

Front View

1

2

3

4

5

6

9

12

14

13

15

11

8

7

10

1

Transport Power Switch – Turns the T-750 transport power ON.

2

Speed Control – This dial adjusts the transport speed of the tabber.

3

Registration Assembly – Helps align the media against the Media Guide Fence.

4

Take-up Reel – The tab web waste is wound up here after the tab is applied.

5

Tab Drive Rollers – Advances the Tabs/Stamps.

6

Tab Reel – The tabs or stamps are loaded on this assembly.

7

Tab Reel Side Guide – Secures the Tabs/Stamps onto the Tab Reel.

8

Unwind Drive Rollers – Unwinds the tabs/stamps from the roll to keep the bin full.

9

Bin – Provides an area for a loop of tab/stamp web to accumulate.

10

Tab Positioning Knob – Used to adjust the tab fold point or vertical stamp position.

11

Exit Roller Assembly – This assembly presses the tab to the media and provides

sufficient transport pressure, so the media properly exits the tabber.

12

LCD Display – Displays the status of the T-750 and displays the Menu features.

13

Emergency Stop Button – Stops the tabber when pressed. Turn clockwise to release.

14

Control Panel – The machine is controlled and programmed from this panel.

15

Media Thickness Control Knob – Adjust for the thickness of the media.

7