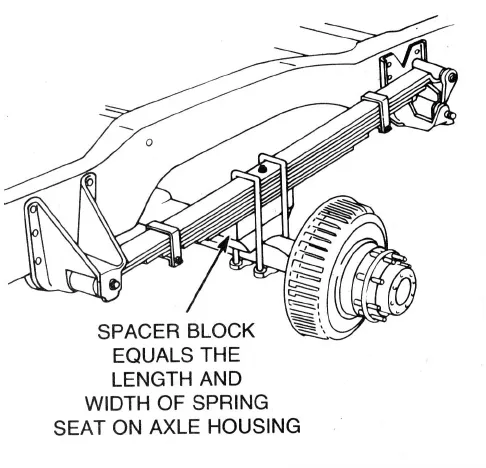

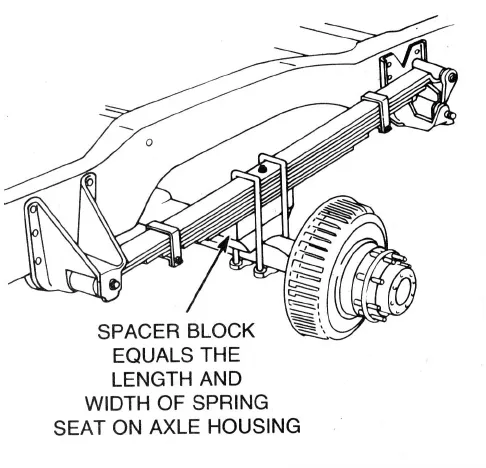

measurement equal. (This supposes that the weight is not in excess of the axle rating and you

have moved your movable stuff around to help balance the side-to-side weight.) Spacer

blocks are fabricated in local machine shops.

NOTE: The addition of a spacer block ( 2 ½” wide, 6” long, thickness as needed) can

actually improve overall ride quality while the addition of a leaf tends to reduce the ride

quality of the vehicle. A new motorhome manufactured with an extra spring on one side is a

bad design. They didn't get the weight balance right and compensated with the springs. You

would also have to be very careful in this situation with the tire inflation. The heavier side is

the weight to use to determine the correct pressure for all tires on that axle. You cannot

simply divide the total axle weight in half in this situation – that can be dangerous.

The thickness of the spacer block is determined by the difference in the side-to-side

measurements at the rear axle. Once the thickness is determined and the block fabricated, a

¾ inch hole is drilled in the center. A slip-fit dowel, as long as the thickness of the spacer

block, is inserted into the hole of the block. This keeps the center of the axle and the

existing spring properly aligned. The U-bolts will need to be replaced with longer ones if the

spacer block is more than ¾” thick. Also, the rear flexible brake hose that runs from the

frame to the axle may need to be lengthened since you are increasing the distance from its

mount on the frame to the connection on the axle. Check by slowly lifting the rear by the

frame and allow the rear axle to hang loose. Be careful to check while doing this so you

don't accidentally rip up that brake hose in case it is too short.

Modifying the rear side-to-side measurements will affect the front side-to-side measurements

Main Body Page 13 of 38 Total Pages