CHERY·A21 SERVICE MANUAL ENGINE EFI SYSTEM

23

conquer Return spring pressure, needle valve

gravity and friction force, the needle valve begin to

rise up and start the injection process. The pressure

of return spring makes needle valve close again

when the injection impulse is stopped.

5)Working voltage:6— 16V

Working injection pressure: 350KPa

6)Malfunction and diagnosis method

Malfunction: badness idle speed, badness

acceleration, can not start (difficult to start) etc..

Reason: lack of maintenance causes invalid by

the colloid inside of injector became insulation

layer.

Simple measure method: (disconnect the joint)

leave digital multimeter at ohm shift, connect the

meter pen to the two pins of injector. The rated

resistance should be 11 - 13Ωwhen it is 20★.

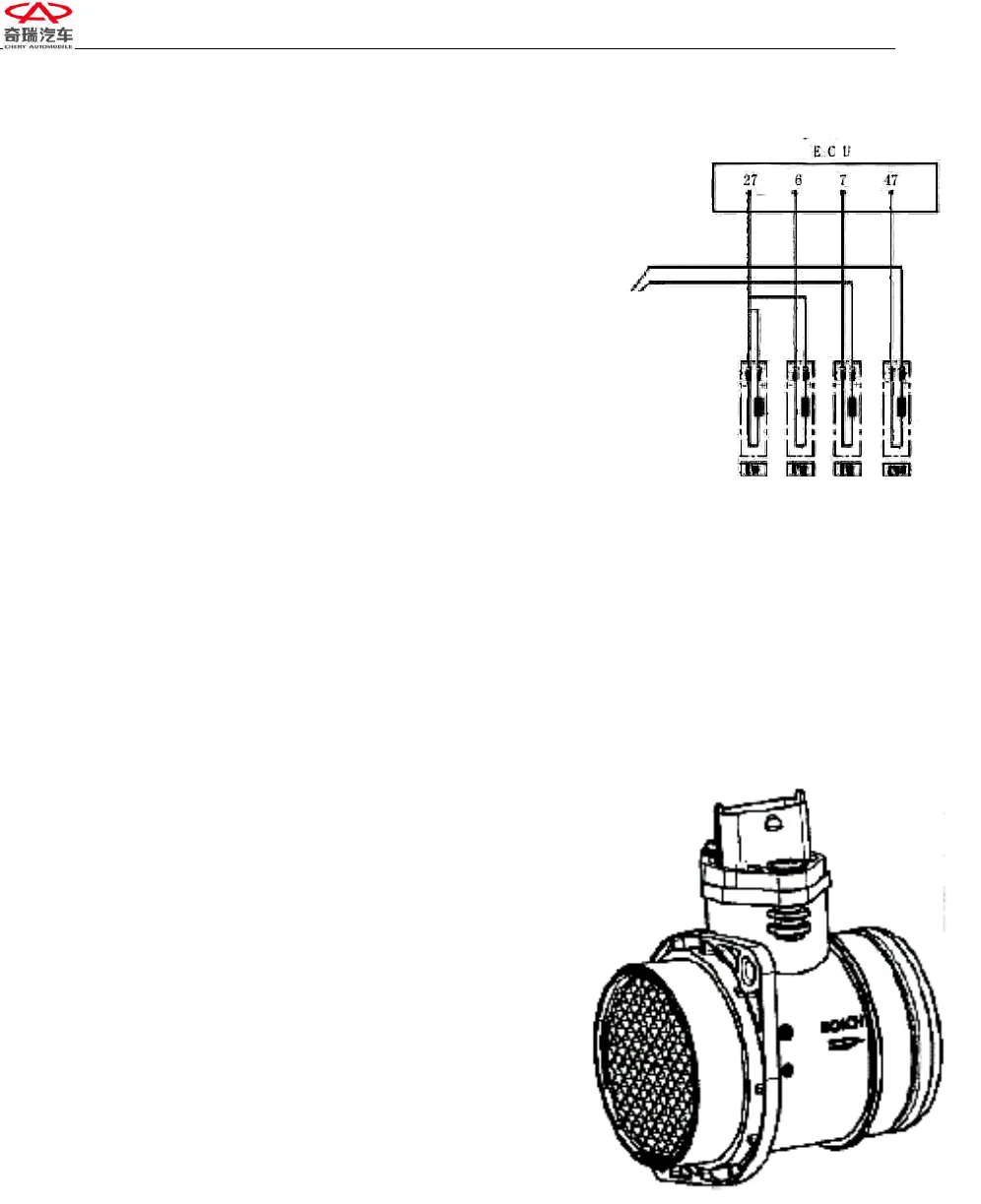

3.9 AIR FLOW SENSOR

1)Exterior drawing and pin definition

This sensor is 5 pins: No. 1 is intake temperature

pressure signal; No. 2 is accumulator pressure; No. 3

is grounding; No. 4 is reference voltage 5V; No. 5 is

intake airflow signal output.

2)Installation position

It is behind the air cleaner of the air intake tube.

3)Purpose:

This sensor is hot cable airflow sensor, which check

the temperature and air intake flow entering to

cylinder and provide evidence to ECU to calculate

fuel injection quantity.

4)Working principle

If there are no airflow passing when the air quality

and flow meter works, temperature grads of both

sides of the heating area spread symmetry, and

temperature of these two points are same. When the

air passes here just one way, the air will be heated

when it passes the central heating area and this will

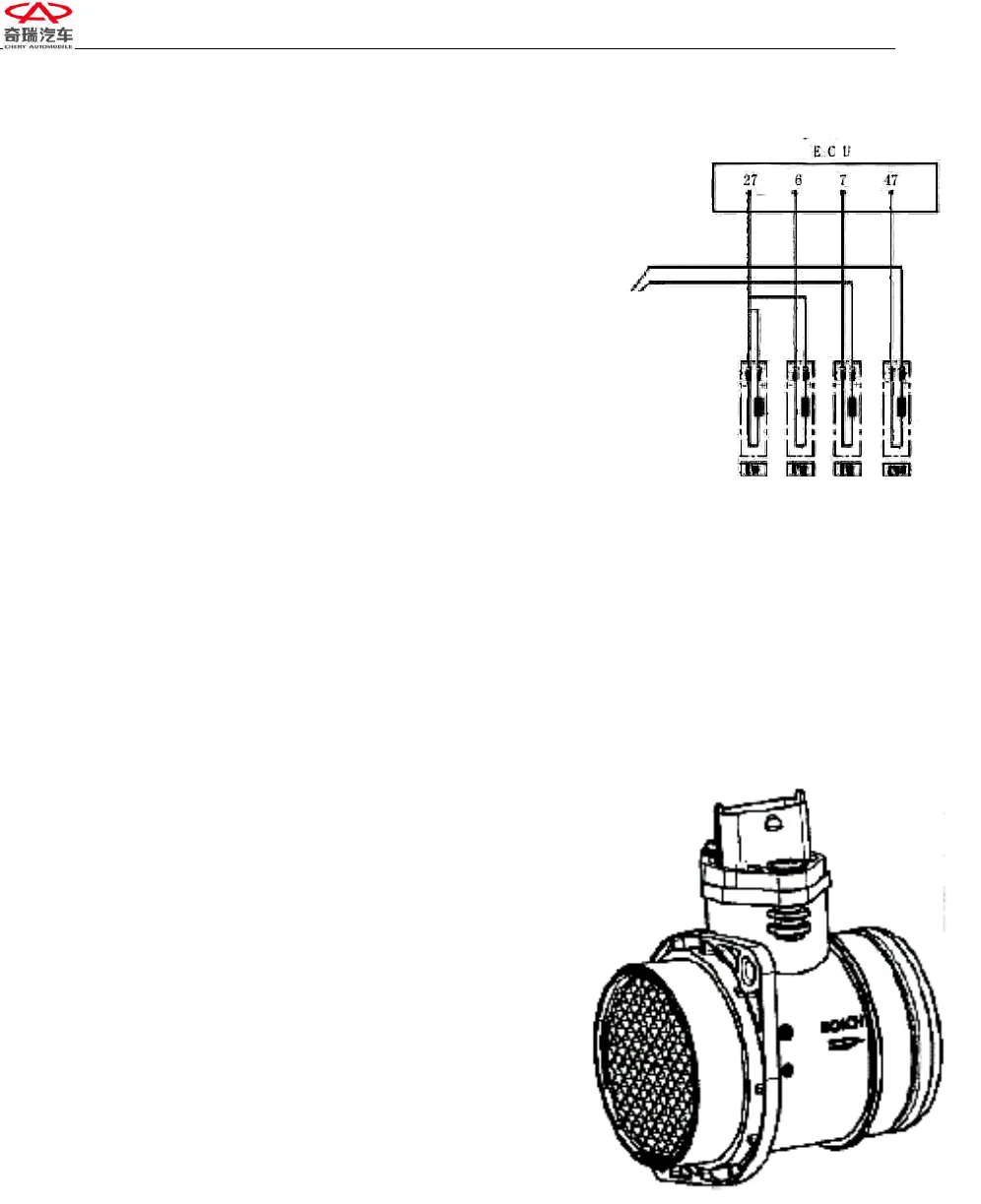

Connect

Relay Pin No. 87

Cylinder No.1, No.2, No.3, No.4

Chart 3-16 Circuit Diagram of Injector

Chart 3-17 Exterior

Sensor