4076-0XX

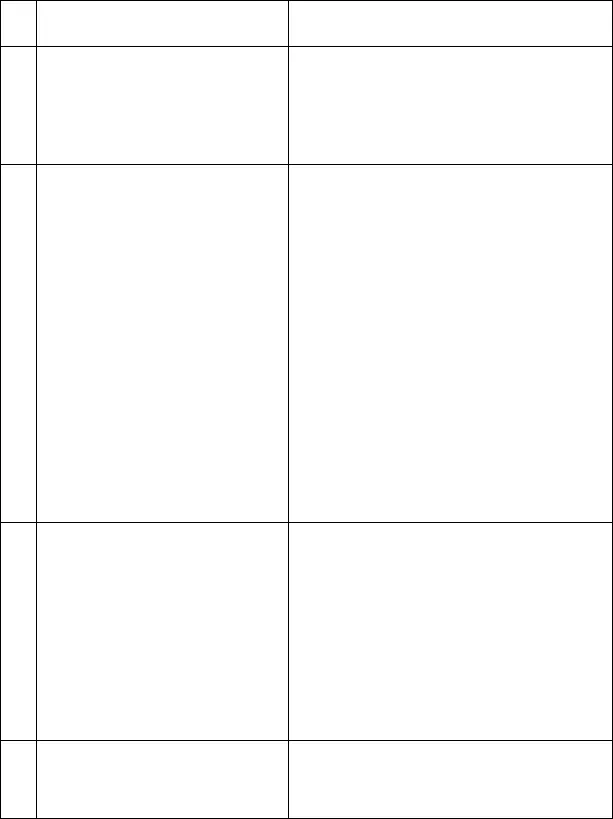

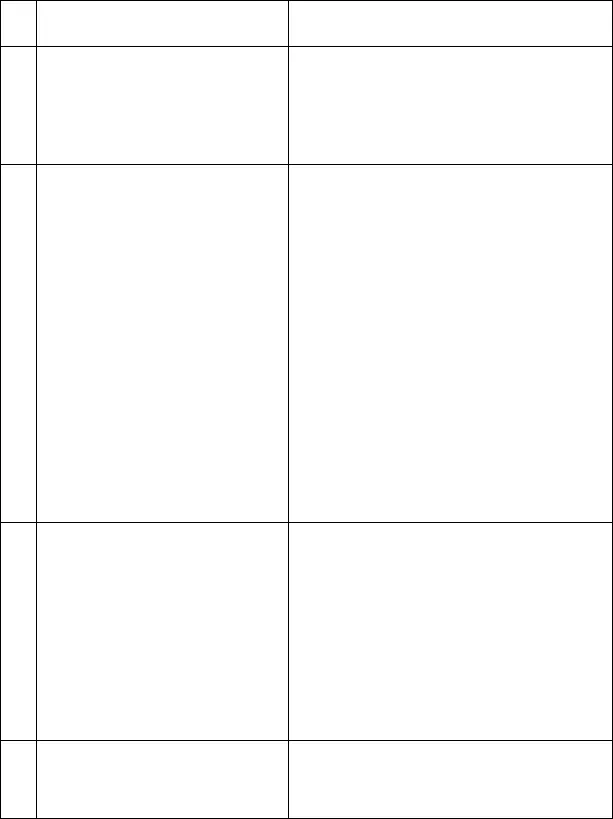

Diagnostic Information 21

4 Maintenance Station Intermittent nozzle failures can be

caused by worn parts in the mainte-

nance station. Go to and perform the

“Maintenance Station Service Check”

on page 12, then return to this check.

5 Paper Feed Ink smudging and smearing can be

caused by paper problems or prob-

lems in the paper feed area. Check:

• Correct type of paper is in the

machine. Also check the paper for

curl and wrinkles.

• Feed roller for wear, dirt, or loose-

ness

• Gears for wear or binds

• Paper path for obstructions

• Star rollers for binds or dirt. The exit

roller and star rollers keep tension

on the paper by moving slightly

faster than the feed rollers. A bind-

ing star roller can put vertical marks

on the paper.

6 Transport Blurred print and voids can be caused

by problems in the transport area.

Check the following:

• Transport belt for wear.

• Carrier guide and carrier guide rod

for wear or dirt.

• Idler pulley parts for wear, damage,

or looseness.

• Encoderstripforwearordirt.

7 BiDirectional Alignment Uneven vertical lines can be adjusted

by performing the “Bi-directional

Alignment Adjustment” on page 31.

FRU OR PROCEDURE ACTION