Table 2 - Setting Safety Controls (Contd)

SAFETY OR CONTROL DEVICE RECOMMENDED SETTING

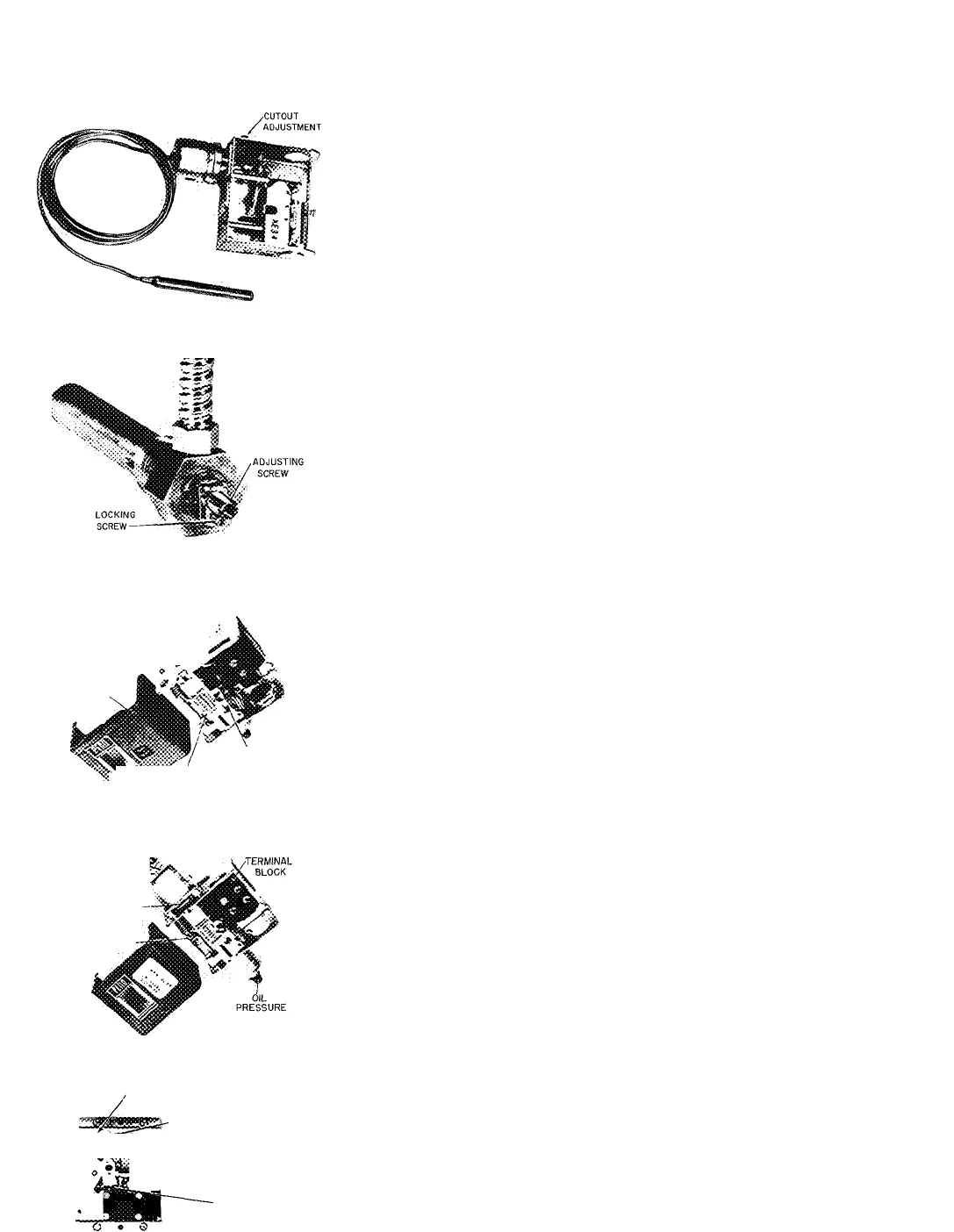

2. Refrigerant Low-Temperature

Cutout (Fig. 1)

1. Install jumper wire or mechanical block in the chilled

water low-temperature cutout and recycle control.

2. Set the refrigerant low-temperature cutout at 33 F while

reading the temperature gage on side of float chamber.

3. Remove jumper wire or block.

3. Oil Heater Thermostat (Fig. 1)

Set the oil heater thermostat to maintain a minimum oil

reservoir temperature of 145 F at shutdown.

4. Condenser High-Pressure

Cutout (Fig. 1)

CUTOUT ADJUSTMENT .-••c '

COVER-

The condenser high-pressure cutout switch is factory set

to shut the machine down when the condenser pressure

reaches approximately fifteen psig. Isolate the switch, and

check switch setting with a metered supply of air.

RESET

„

......

..........

.

, BUTTON

CUTOUT SCALE

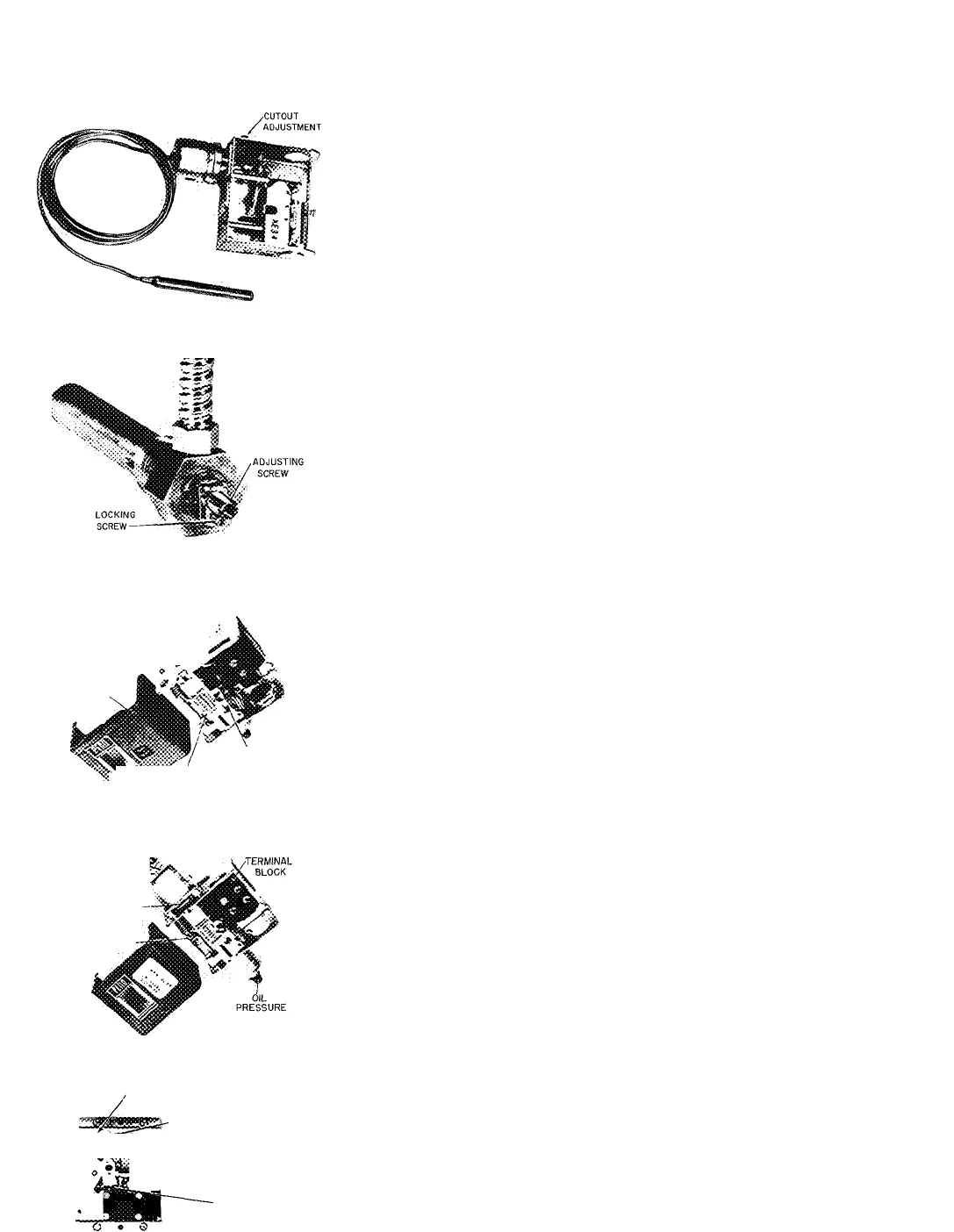

5. Low Oil Pressure Cutout (Fig. 1)

RANGE (CUT-IN) .

DIAL ADJUSTMENT

REMOVE METAL

COVER

------

CUTOUT

ADJUSTMENT

Opens switch contacts on drop in oil pressure. Cutout at

9 psi differential. Cut-in at 14 psi differential. While op

erating pump manually, note and record reservoir pres

sure on gage. Remove cap and gasket from oil pressure

regulating valve. Loosen locknut. Turn adjusting screw

counterclockwise to lower oil pressure to within 4 psi of

reservoir pressure. Reset differential to adjust cutout. Set

range (cut-in) by turning adjusting dial clockwise, raising

oil pressure.

6. Antirecycle Timer (Fig. 1)

/TIME SETTING

'LOCKNUT

' N

TIMER

SWITCHES

Time setting is factory set for 20 minutes. Limits the num

ber of machine starts to three per hour.