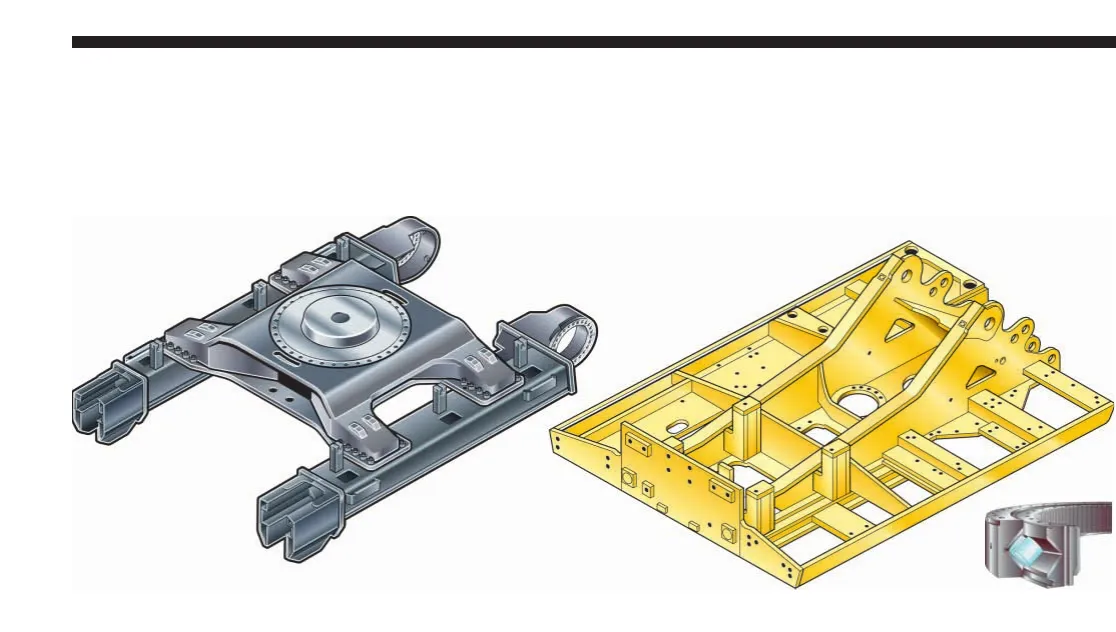

Carbody Design. The advanced carbody

design stands up to the toughest

applications.

• Modified X-shaped, box-section

carbody provides excellent

resistance to torsional bending.

• Upper structure weight and stresses

are distributed evenly across the full

length of the track roller frame.

• Robot welding ensures consistent,

high-quality welds throughout the

manufacturing process.

Upper Frame. Rugged main frame is

designed for maximum durability and

efficient use of materials.

• Robot welding for consistent,

high-quality welds.

• Outer frame utilizes curved side

rails, which are die-formed, for

excellent uniformity and strength

throughout the length.

• Box section channels improve

upper frame rigidity under the cab.

• Boom tower and one piece main

rails are constructed of solid,

high-tensile strength steel plates.

• New boom foot design transfers load

more efficiently with less stress in

critical areas.

• Reinforced lift cylinder and swing

drive mounts increase structure

durability in rock and quarry

applications.

Cross-roller Bearing. The 365C L

swing bearing is a cross roller type,

with 54 mm (2.13") diameter rollers.

The cross rollers have a much greater

contact area than ball bearings,

providing increased stability and

longer life.

Track Roller Frames. The track roller

frame is made of thick steel plate that

is bent into a U-shape and welded to

the bottom plate to create a box structure.

The box structure design provides

increased rigidity and impact resistance.

Variable Gauge Undercarriage.

The long variable gauge undercarriage

is standard, providing a wide, stable base

for operating, or a narrow gauge for

reduced shipping width. The track roller

frames are bolted to the carbody, and

can be placed in two positions.

10

Structures

The 365C L structural components are the backbone of the machine’s durability.