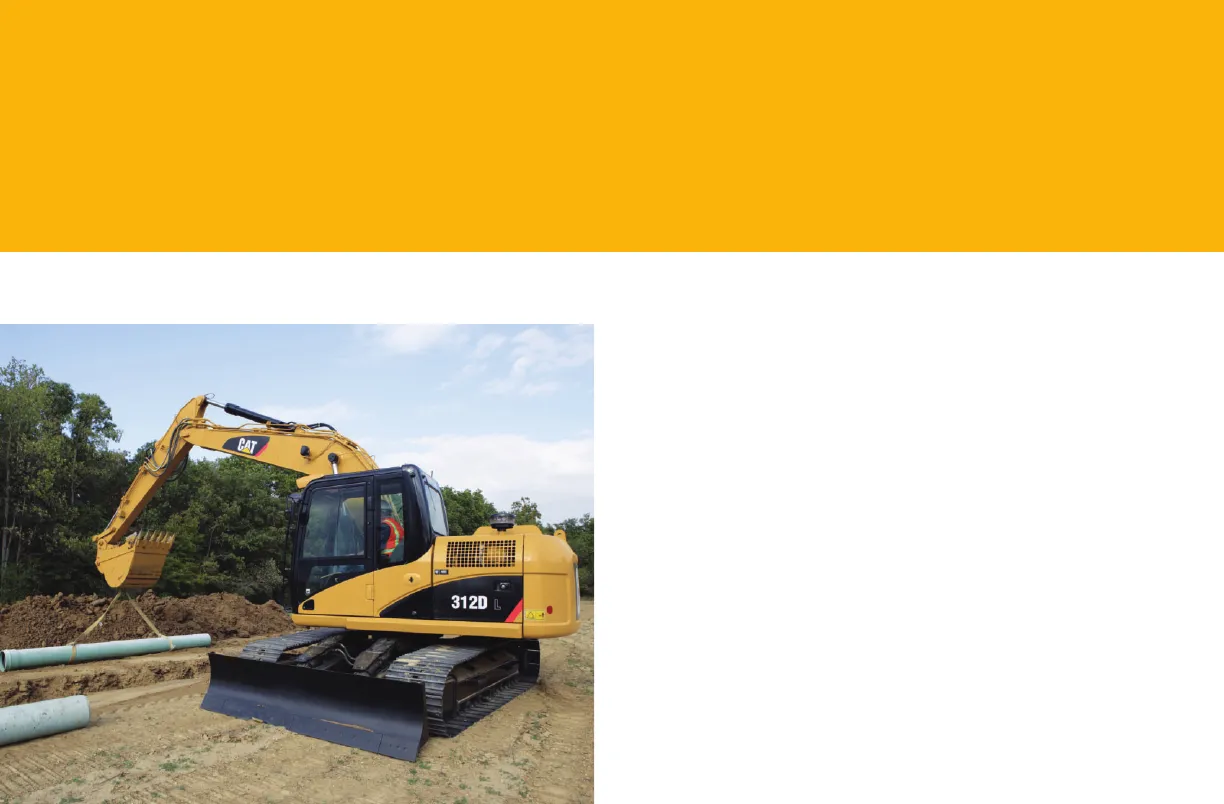

Hydraulics

Low effort and precise control for highly efficient performance

Outstanding Performance

With two percent more hydraulic pressure for additional lift

and breakout forces, the 312D hydraulic system is designed

for high efficiency and performance. Auxiliary hydraulic and

electrical lines are routed to the boom foot making installation

of hydraulic circuits much easier. This compact design utilizes

short tubes and lines, reducing friction and pressure drops,

resulting in a more efficient use of power.

• Hydraulic snubbers at the rod end of the boom cylinders and

both ends of the stick cylinders cushion shock, reduce sound

and increase cylinder life.

• Flow is reduced to a minimum when controls are in neutral

to reduce fuel consumption and extend component life.

• Electronic Under Speed Control electronically adjusts pump

output to not exceed engine power, preventing the need to

reserve engine power to avoid engine stalls.

• Hydraulic Cross-Sensing System uses two hydraulic pumps up

to 100 percent of engine power under all operating conditions,

improving productivity with faster implement speeds and

quicker, stronger pivot turns.

Boom and Stick Regeneration Circuit

The boom and stick regeneration circuit saves energy during

boom-down and stick-in operation, increasing efficiency and

lowering operating costs.

Easy Operation

Work mode and power mode switches have been eliminated

making full power available at all times. Operators do not need

to learn different modes, an automatic boom and swing priority

function automatically selects the best mode based on joystick

movement.

5