U

The Citroën Guide Fuel Injection: Diesel engines 15

Electronic Diesel Control

Just like it is the case with gasoline engines and carburetors,

a mechanical device—even one as complicated as a diesel

injection pump—cannot match the versatility and sensibil

-

ity of a microcomputer coupled with various sensors, apply

-

ing sophisticated rules to regulate the whole process of fuel

injection.

The only input a mechanical pump can measure is the en

-

gine speed. The amount of air entering into the engine, un

-

fortunately, is far from being proportional to engine speed,

and the turbo or the intercooler disturbs this relationship

even further. As the injection always has to inject less fuel

than the amount which would already generate smoke, the

mechanical pump—capable only of a crude approximation

of what is actually going on in the engine—wastes a signifi

-

cant amount of air, just to be of the safe side.

The satisfactory combustion in diesel engines relies on

the exhaust as well—if this is plugged up, more of the ex

-

haust gases stay in the cylinder, allowing less fresh air to en

-

ter. A mechanically controlled injection pump has no feed

-

back from the engine (except for the engine speed)—it will

simply pump too much fuel into the engine, resulting in

black smoke. An electronically controlled injection pump,

on the other hand, can tell how much air has actually en

-

tered by using a sensor (although only the latest systems

use such a sensor).

There are also other factors never considered by a me

-

chanical system. The details of the combustion process de

-

pend heavily on the chemical characteristics of the fuel. The

ignition delay, as we have already seen, depends on the

cetane number of the diesel oil. In spite of the fact that cor

-

rect timing has a paramount influence on the performance

and the low pollutant level of a diesel engine, the mechani

-

cal system can have no information about this very impor

-

tant input factor. Less essential but still important is the tem

-

perature of the incoming air. With measuring all the circum

-

stances and conditions in and around the engine (air, en

-

gine and fuel temperatures), the injection system can

achieve better characteristics, lower fuel consumption and

less pollution.

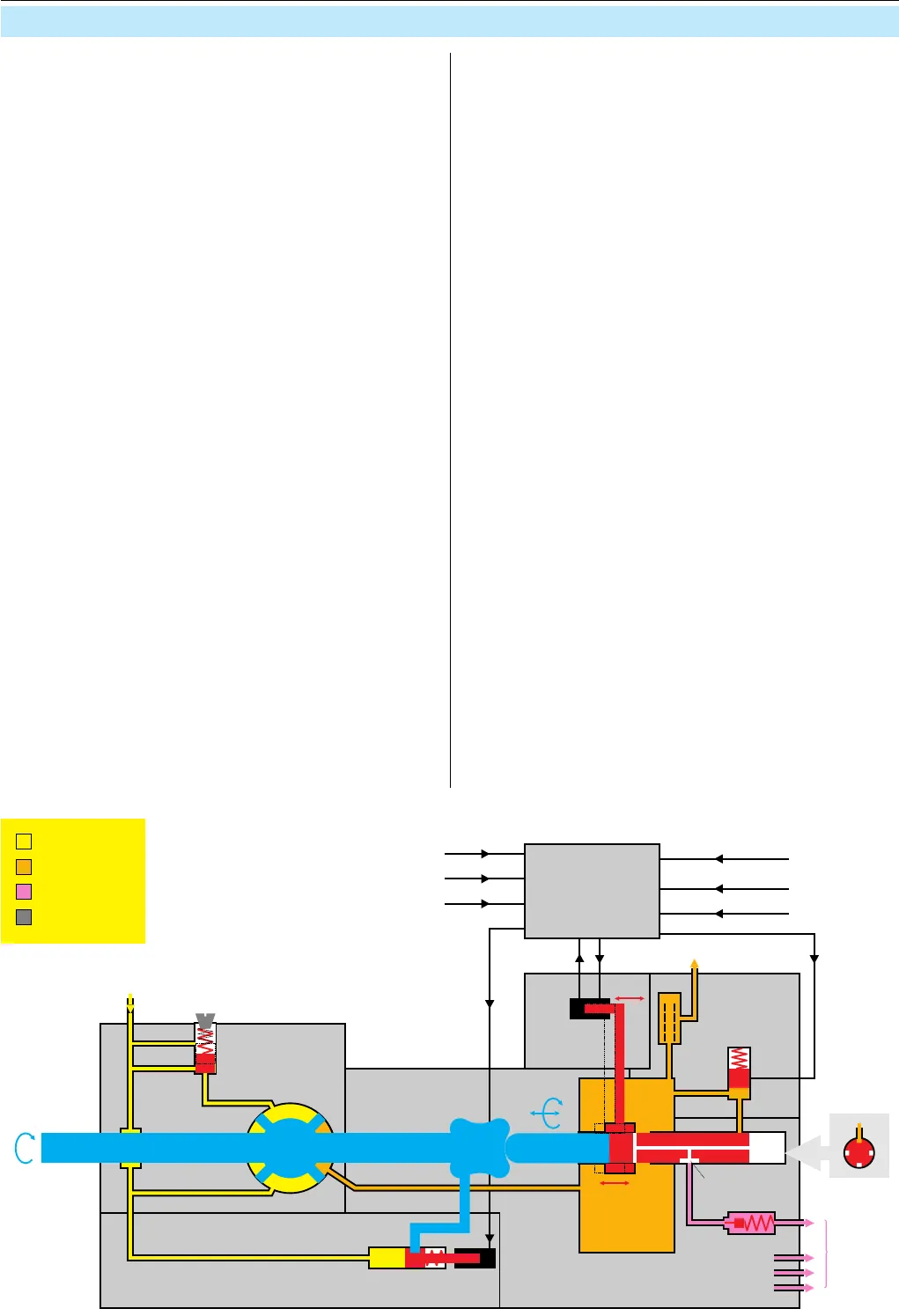

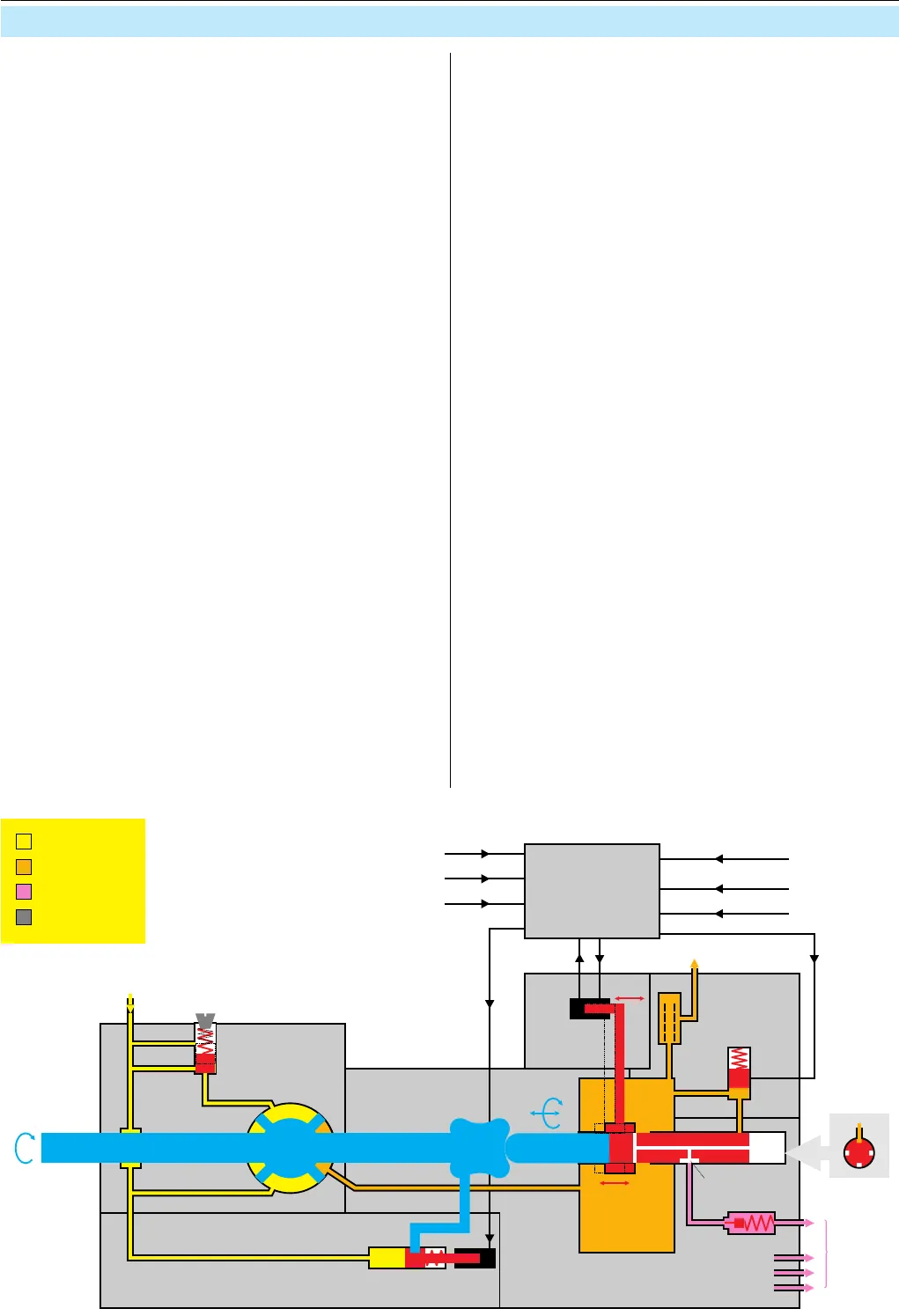

All in all, the electronically controlled injection pump not

only adds precision to the injection process as its gasoline

counterpart does but introduces completely new methods

of regulation; therefore it represents a much larger leap for

-

wards than fuel injection in gasoline engines. In spite of

this, it is quite similar to its mechanical predecessor. From

the five subparts, four remain practically the same, only the

regulator is replaced with a simple electromagnetic actua

-

tor that changes the position of the same regulator collar 5

as in the mechanical pump, in order to regulate the amount

of fuel to be injected.

The real advantage over the former, mechanical pumps

is that an electronic device, a small microcomputer can han

-

dle any complex relationship between the input values and

the required output. With mechanical systems, only simple

correction rules are possible, and as the rules get more com

-

plicated, the mechanics quickly becomes unfeasible. In con

-

trast to this, the ECU just have to store a set of characteristic

curves digitized into lookup tables, describing the amount

of fuel to be injected using three parameters: engine

speed (measured by a flywheel inductive magnet), cool

-

ant temperature (measured by a sensor protruding into

the coolant liquid), air temperature (measured by a sen

-

sor in the air inlet).

The newer HDi engines use an air mass sensor using a

heated platinum wire (as that mentioned on page 5). Hav

-

ing the exact amount of air to enter the engine, these latest

EDC systems can deliver true closed loop regulation.

A potentiometer attached to the accelerator pedal

sends information about the pedal position to the com

-

puter. This signal is used as the main input, conveying the in

-

engine

fuel from/to tank

low pressure

high pressure

adjusting screws

fuel pump

2

injection

adjuster

high pressure pump

and distributor

fuel stop

valve

actuator

fuel

1

4

5

6

fuel

to tank

7

injectors

Û

accelelator

pedal

à

â

ã

ä

6

ECU

temperatures

(air, fuel, coolant)

regulator

position

vehicle speed

air quantity

engine speed

atmospheric

air pressure

ß

8