Start-Up Demand — Steam demand by the absorp

tion machine is greatest at start-up (see Table 1 for

values).

Table 1 — Maximum Condensate Flow (Ib/hr)

VALVE VALVE INLET STEAM PRESSURE

SIZE (in.)

20 psig

14 psig

12 psig 10 psig

2

2450 2025

1880 1750

2Y2

4825 4000

3710 3430

3

8175 6760

6285 5810

4

14540 12025

11190 10350

5

21650

17900

16655 15400

When boiler capacity is unable to keep up with

start-up demand, the steam pressure will fall off.

On boilers serving only the absorption machine,

this reduction in steam pressure will have no

adverse effect on the absorption machine other

than to lengthen start-up time. However, the

increased steam demand may have an adverse

effect on the boiler, causing it to run dry and fail.

As steam pressure is reduced, the steam control

valve pressure drop will eventually limit the de

mand on the boiler provided the steam control

valve is properly sized.

On boilers serving other loads simultaneously,

the start-up demand can reduce boiler pressure

sufficiently to cause adverse effects on other

steam-driven equipment. When a reduction in

boiler pressure cannot be tolerated without up

setting other equipment, the boiler capacity avail

able for absorption machine operation (with other

loads deducted) must equal or exceed the start-up

demands. If it does not, the start-up demand can

be reduced by using demand Hmit controls, or

installing a back-pressure regulator in the steam

line(s) between the boiler and the control valve(s).

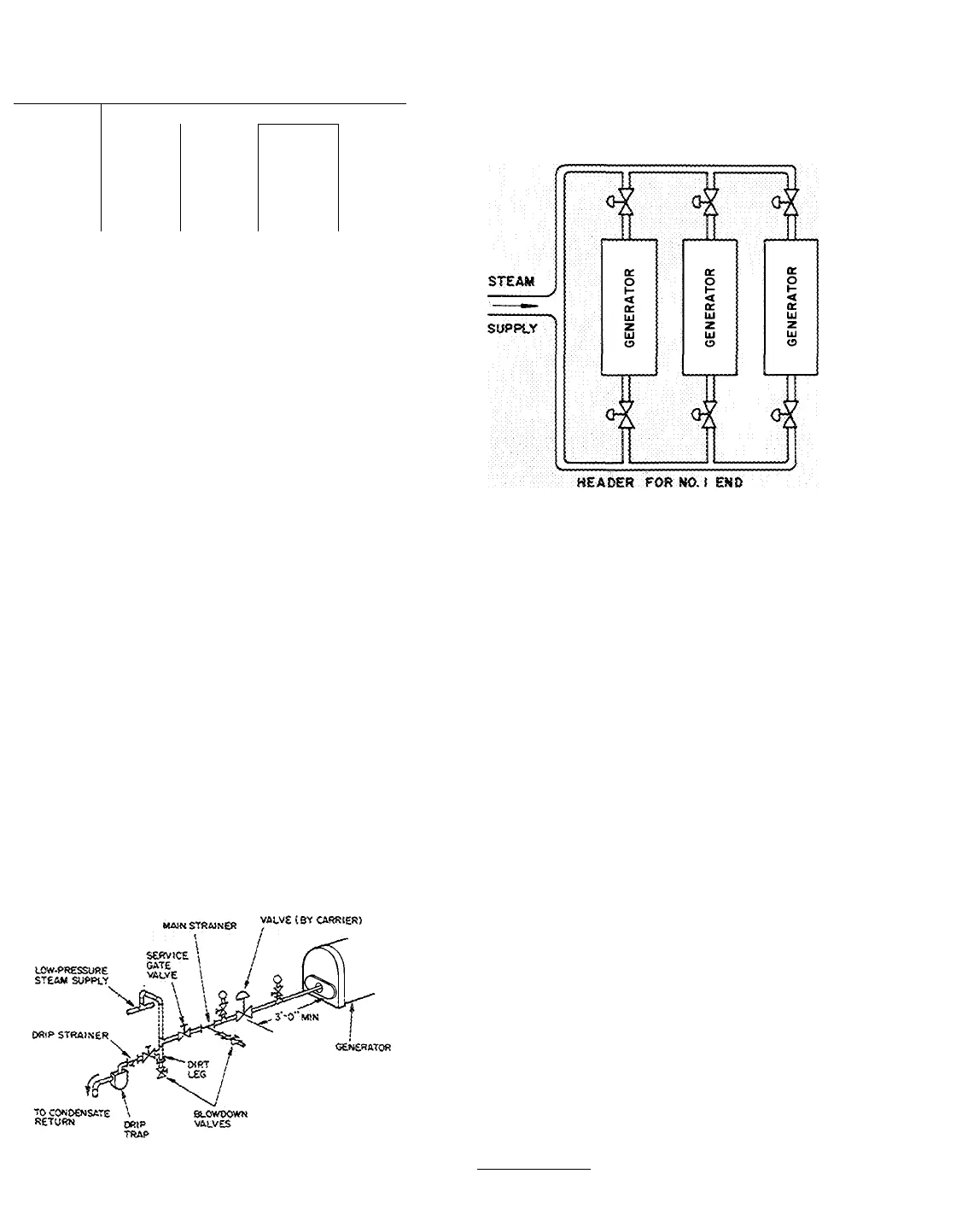

VALVE LOCATION AND PIPING - The steam

control valve should be located a minimum of 3 ft

away from the generator inlet. This is dictated by

good piping practice, to allow equal distribution of

steam in the generator tube bundle. Unequal

distribution of steam in the tube bundle may cause

a loss of capacity. Recommended steam supply

piping for low-pressure steam applications is

illustrated in Fig. 1.

STEAM CONTROt

NOTE; Separate supoiy piping "for each end of machine sizes

16JB077 thro '24,

Fig. 1 — Low-Pressure Steam (2 to 15 psig)

Supply Piping

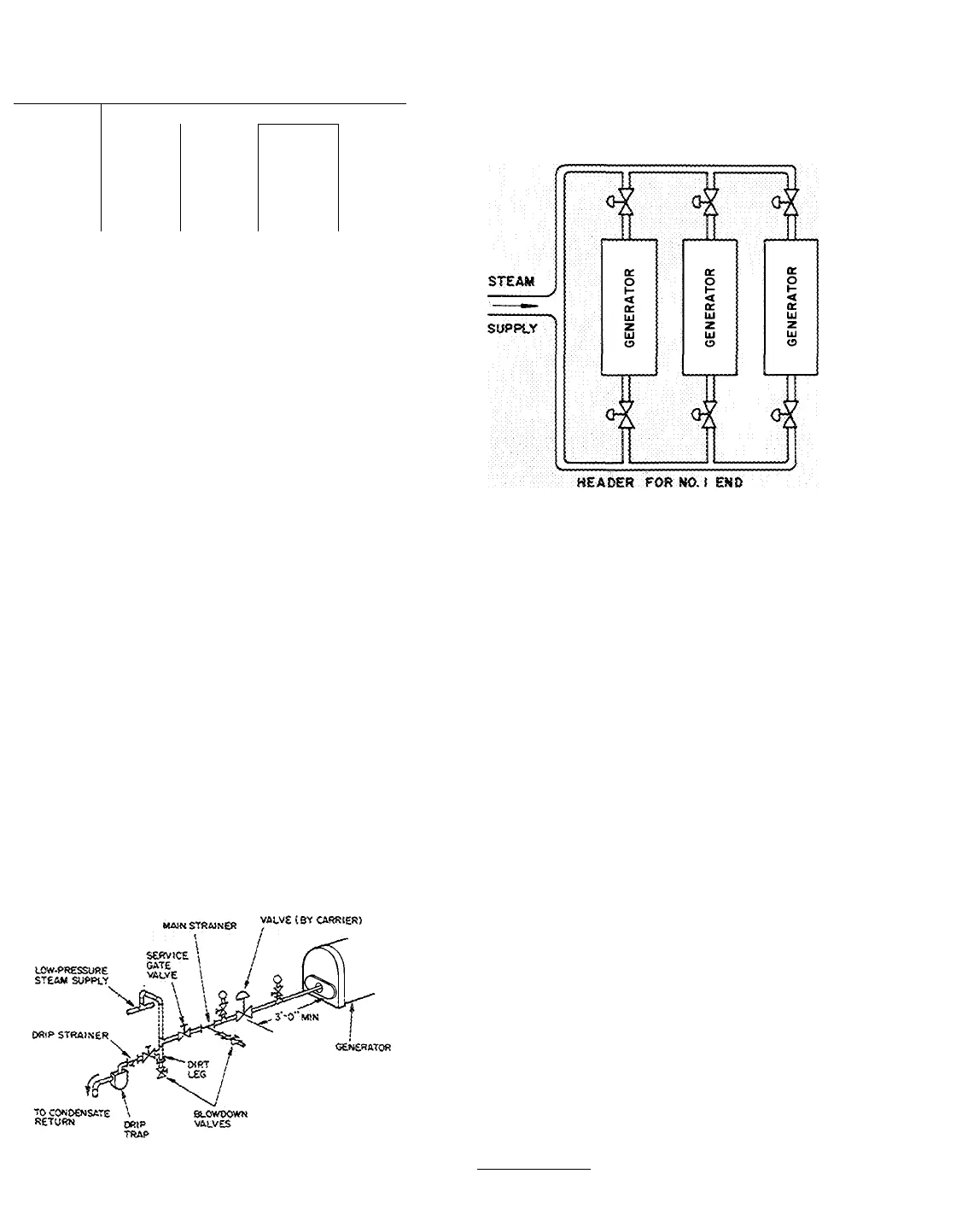

Machine sizes 16JB077 thru 16JB124 have

steam supply inlets on each end. These are to be

considered as two generators and should be piped

from a common steam header as in multiple

machine installations (see Fig. 2). Each inlet should

then be piped in accordance with Fig. 1.

HEADER FOR N0.2 END

NOTES:

1. Piping appiies to moitipie macbiries connected in paraiief

(3 shown).

2. Each end most be consdered as a separate generator.

3. The feed to each end of each generator should be piped as

shown in rig. 1.

Fig. 2 — Steam Piping For 16JB077 thru 124

Steam piping to the absorption machine should

be designed and supported to allow for thermal

expansion without imposing undue stresses on the

generator inlet. The machine is not designed for,

nor expected to act as, a piping support or anchor

for withstanding thermal stresses.

Condensate Systems — Satisfactory operation of

the absorption machine requires a condensate

handling system designed with the specific char-

acteristics of the absorption machine in mind. The

following is intended to supplement available

reference data on condensate systems such as

Carrier System Design Manual, ASHRAE Guide

and individual manufacturer’s recommendations.

ATMOSPHERIC CONDENSATE RETURN

SYSTEMS (VENTED) - These systems usually

consist of steam traps, vented receiver, condensate

pump, and condensate cooler. Fig. 3 illustrates

typical atmospheric condensate return systems. On

larger machines, with dual steam generators, the

condensate outlet from each generator must be

piped thru separate steam traps.

Trap Selection — Steam traps should be located as

far below the generator outlet as possible. Actual

pressure drop available for trap selection will

depend on exact trap location below the generator