36

Engine management

The Bosch MED 9.1.2 measures load by means of the intake mani-

fold pressure sender G71 and the engine speed sender G28.

The target for emission classification was compliance with exhaust

emission limits EU 5. This was achieved by using the following

subassemblies in combination with special injection and catalyst

heating strategies:

• Intake manifold with intake manifold flaps

• Multi-port injectors in combination with flat pistons

• Close-coupled pre-catalyst

A secondary air injection system was not needed.

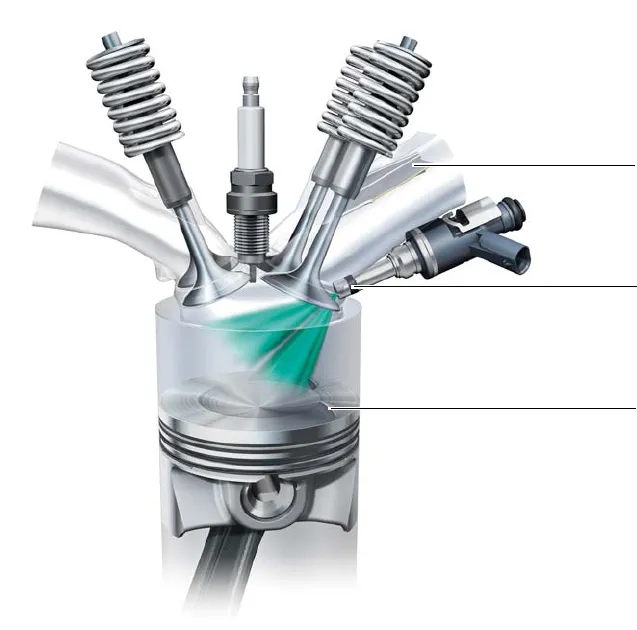

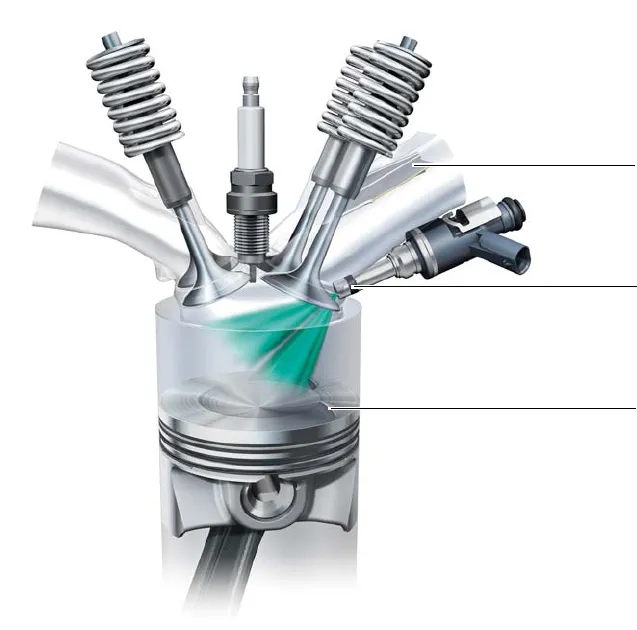

451_053

Combustion process

The basis for the development of the combustion process was the

Audi 2.0 litre TFSI engine. Like this engine, the 2.5 litre TFSI unit

benefits from the acknowledged advantages of multiport valve

technology, as shown in diagram 451_053.

Optimised tumble intake port

Spray-optimised six-port high-

pressure injector

Flat-crown piston

Operating modes

The following operating modes are possible:

• High-pressure stratified starting down to an ambient tempera-

ture of -26 °C

• Catalyst heating and engine warm-up with twin injection

• When the engine is warm and running at low rpm, the amount

of residual gas in the cylinders is minimised by high scavenging

rates, achieved by adjustment of the intake and exhaust cam-

shaft phasings and by adaptation of the valve timings and event

duration*.

In the upper rpm band, the entire system is optimised for high

flow rates. In this regard, it is essential that the intake, pressure

and exhaust lines be carefully matched and optimised for pres-

sure losses.

By optimising the spray parameters in combination with a flat pis-

ton crown shape, it was possible to improve carburetion compared

to the 2.0 litre TFSI engine, despite the approx. 25 % increase in

the flow rate of the high-pressure injectors.