SECTION 4

OPERATOR MAINTENANCE

86

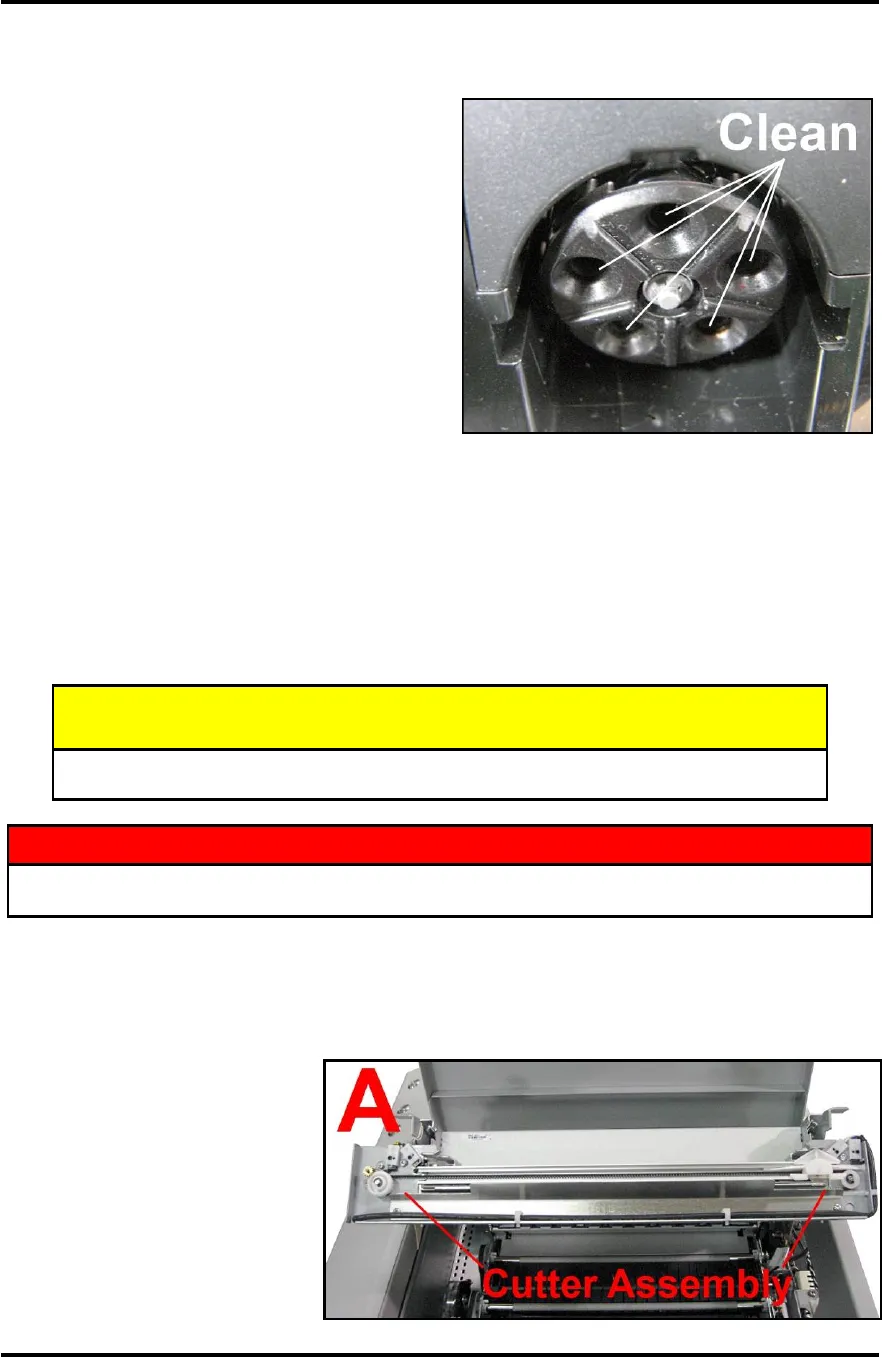

Cleaning the Ink Revolver Couplings

1. First Deprime the system and remove the

Printhead Cartridge.

2. Moisten a foam swab in distilled water.

3. Insert the swab into one of the ink channels

and rotate the swab to clean the chamber.

4. Use a new swab for each of the remaining

ink channels until all 10 openings are clean.

(5 on each side.)

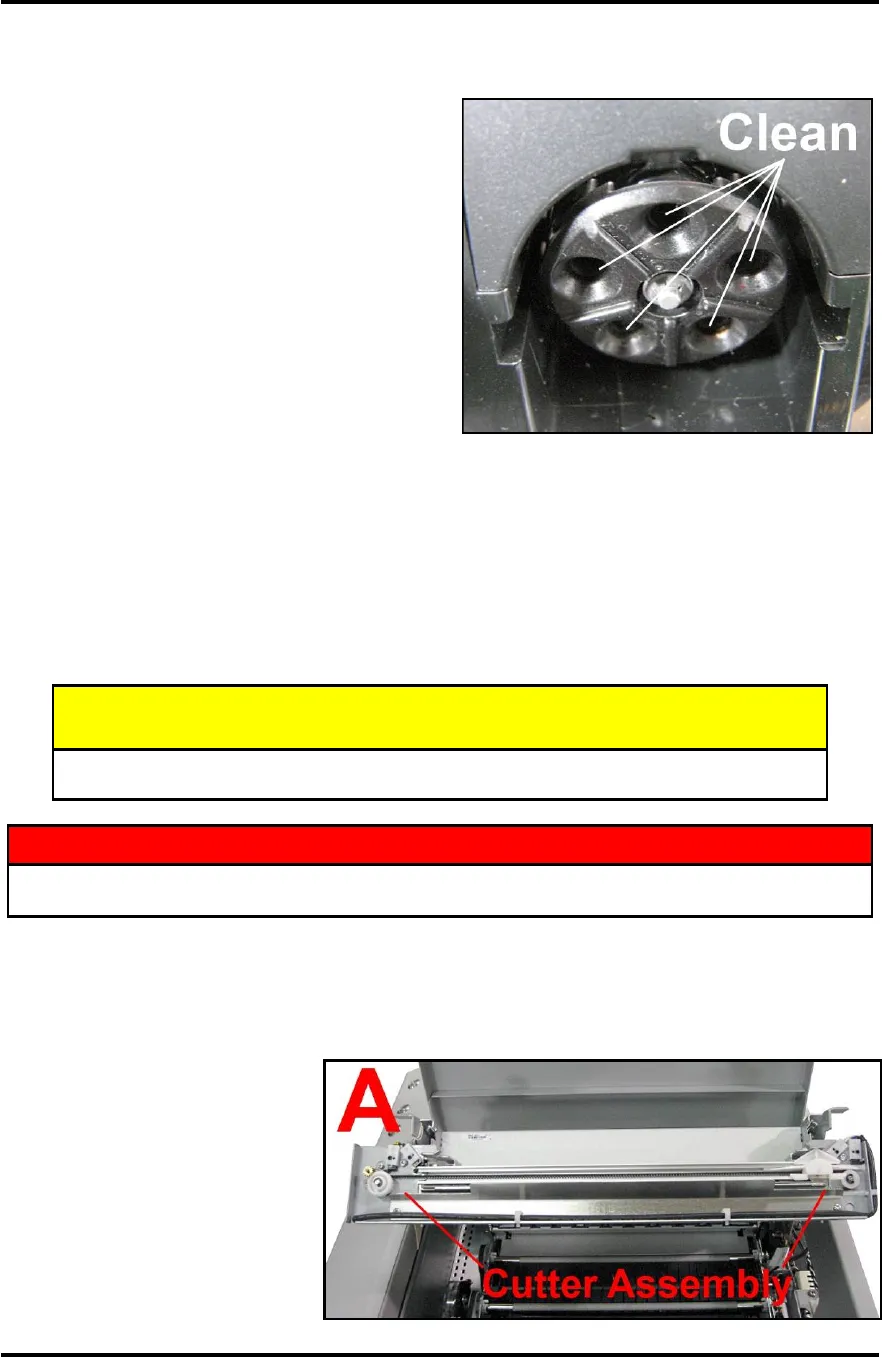

Cleaning the Cutter Assembly

The Cutter (Cutter Assembly) is used to trim and cut the media web. During this process, paper dust,

label/media trimmings and debris may accumulate in this area; affecting Cutter performance.

When activated the Cutter Motor drives the Cutter, from one side to the other, with a lot of force and speed.

To avoid personal injury; you must power down the printer before touching the Cutter Assembly.

Cutter Assembly maintenance should only be performed by a qualified/trained person. Please contact your

service representative to obtain training or to have them perform this process for you.

CAUTION

THIS PROCESS MUST BE PERFORMED BY A QUALIFIED/TRAINED PERSON.

ALWAYS POWER DOWN THE PRINTER BEFORE PERFORMING ANY MAINTENANCE; TO AVOID

SERIOUS SHOCK OR INJURY.

1. Turn Off the Printer and disconnect power. Power-down the Print Engine using the ON/OFF

button, then Turn Off the Main Power Switch and disconnect the power cord from the printer.

2. Using a vacuum and a pair of tweezers, carefully remove any dust and debris from within and

around the Cutter Assembly [A] area. If needed; the Clamshell can be opened to improve access.