Programat

®

CS

– Short Instructions

Version 3

Valid as of Software V2.0

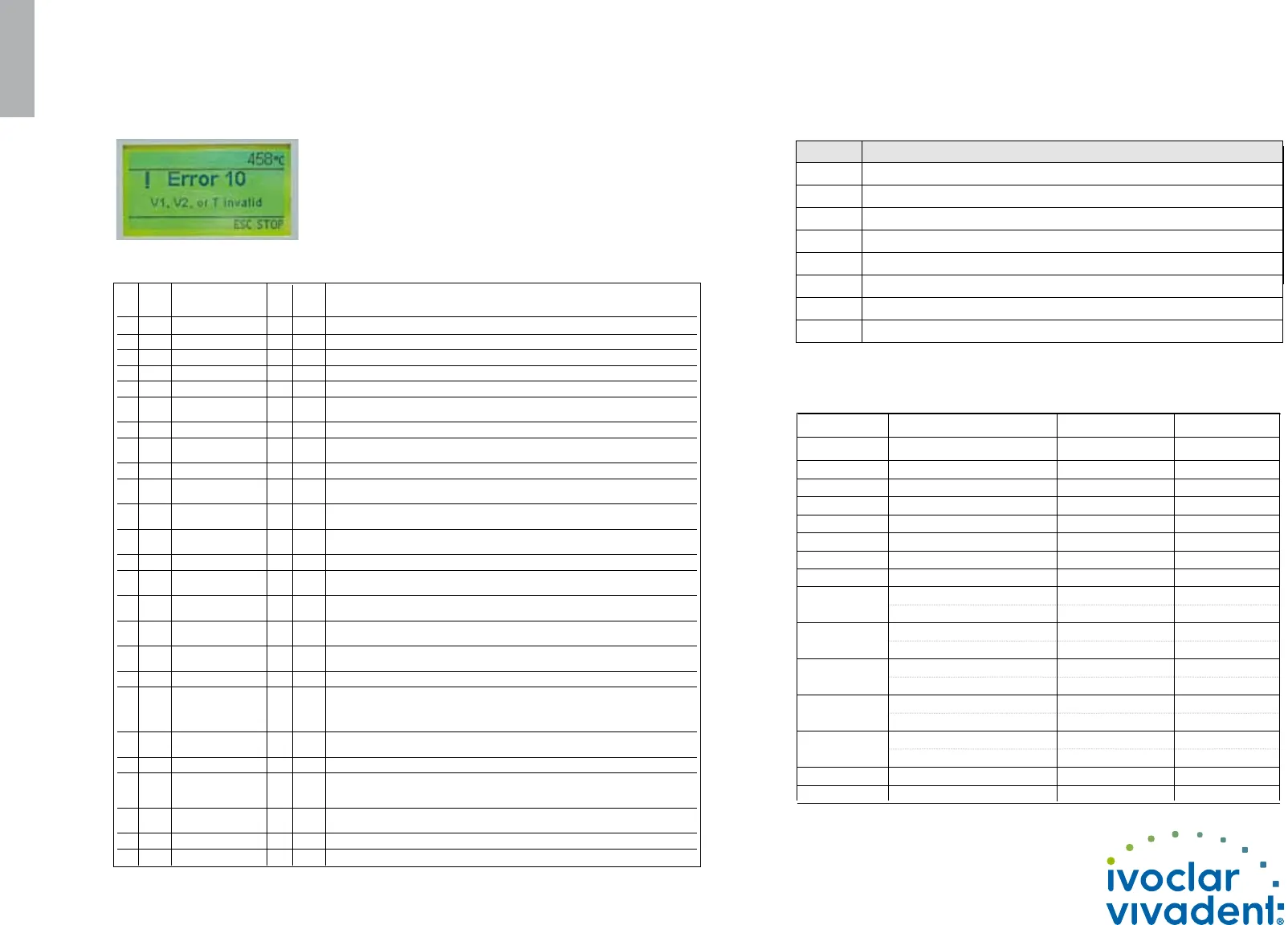

Adjustable parameters and possible value ranges

Program structureError messages

The furnace continuously checks all functions during operation.

If an error is detected, the respective error message is

displayed.

In case of an error, the heater switches off for safety reasons.

Index

Category

Error ERR Conti- Error Message Text

No. nuation

possible

1 Entry T < B 2 Enter a logical value for T

2 Entry L > T 8 Enter a logical value for long-term cooling L

3 Entry V2x <= V1x 9 Enter a logical value for the vacuum-on temperature Vx1 or the vacuum-off temperature Vx2

4 Entry V2x > Tx + 1°C 10 Change either the vacuum values or the holding time T

5 Entry

Incorrect values for V1x, V2x

11 Enter a logical value for V1x, V2x

6 System Current temperature after 13 Excess temperature! Program aborted, furnace head opens to allow the furnace to cool down.

Start > Tx + 50 °C *, **

8 Entry T2 < T1 16 Enter a lower value for T1 or a higher value for T2.

9 System Power failure > 10 s during 17 A firing program in progress was interrupted for more than 10 s. The program cannot be continued!

a firing program in progress

10 Entry T1 > V12 18 Enter a lower value for T1 or a higher value for V12

11 Entry vV set, but V2 is 19 Pre-vacuum activated! V2 must be higher than B.

missing or invalid

12 System Error in the heating system 20 no Check the heater fuse. If the fuse is O.K., contact your local Ivoclar Vivadent Service Center.

**

13 System Heating muffle very old 23 The heating muffle is very old. It is recommended to replace it. After the error message has been

acknowledged, a firing program may still be started.

14 System Heating muffle defective 24 The condition of the muffle is so poor that is has to be replaced immediately.

16 Entry T is > B + 200 °C at the 26 Firing chamber too hot to start a firing program.

start of a firing program

17 System Furnace head cannot 27 The furnace head cannot be moved to the final position. It might be blocked by an external mechanical

be initialized

**, ***

source! If this is not the case, please contact your local Ivoclar Vivadent Service Center!

18 System The furnace head does not 28 The furnace head does not open/close correctly. The furnace head was manually moved or is obstructed.

reach the target position ** The furnace head must only be moved using the keys intended for this purpose!

21 System

Necessary vacuum (xxxmbar)

33 The vacuum cannot be established. Check the seal of the firing chamber, vacuum hose, vacuum pump,

is not reached within 1 min. pump fuse.

33 Entry HV > H (H2) 110 Enter a lower value for HV or a higher value for H (H2)

35 Entry "Share of the holding time 120 Activate the vacuum during the holding time Tx or deactivate HV.

with vacuum" is activated,

but Vx2 does not

correspond to Tx or Tx+1

38 System Brief power failure during a 702 A firing program in progress was interrupted by a brief power failure. The program is continued!

firing program in progress

45 System Vacuum drop 801 An unacceptable vacuum drop has occurred.

46 System The vacuum does not 802 No vacuum increase could be measured. Check the following points: Is the firing chamber tight (no

increase (self-test) contamination on the sealing surfaces)? Is the vacuum hose connected? Is the vacuum pump connected?

Is the fuse F1 o.k.?

75 System ATK2 calibration: 1302 Error during calibration. Sample may not be correctly inserted. Try again with a new sample and make sure the

Pre-heating to 963 °C ** sample makes ampl contact.

79 Note Calibration reminder 1310 Some time has passed since the last calibration procedure. Calibrate the furnace soon.

80 Note Dehumidification reminder 1312 Some time has passed since the last dehumidification procedure. Dehumidificat the furnace soon.

The following error messages my be displayed:

Please contact the Ivoclar Vivadent After Sales Service, if other error messages being displayed.

Symbol Parameter Value range Value range

P Program number P 1–20

B Stand-by temperature 100–700 °C 212–1292 °F

S Closing time (min : sec) 00:18–30:00

t➚ (*) Temperature increase rate 30–140 °C/min 54–252 °F/min

T Holding temperature 100–1200 °C 212–2192 °F

H Holding time (min : sec) 00.01–60:00

V1 Vacuum on 0 or 1–1200 °C 0 or 34–2192 °F

V2 Vacuum off 0 or 1–1200 °C 0 or 34–2192 °F

t➚ (*) Temperature increase rate

t2➚ Second stage 30–140 °C/min 54–252 °F/min

T Holding temperature

Second stage 100–1200 °C 212–2192 °F

H Holding time

Second stage (min : sec) 00.01–60:00

V1 (V1 2) Vacuum on

Second stage 0 or 1–1200 °C 0 or 34–2192 °F

V2 (V2 2) Vacuum off

Second stage 0 or 1–1200 °C 0 or 34–2192 °F

L Long-term cooling 0 or 50–1200 °C 0 or 122–2192 °F

tL Cooling temperature rate 0 or 1–50 0 or 32–90

(*) 100 V Version: 140°C/min (252°F/min)

Please observe the notes in the Instructions for Use of the corresponding material.

Program Description

1 Crystallization/glaze program for IPS e.max CAD

2 Corrective firing for IPS e.max CAD

3 Speed Crystallization/glaze program for IPS e.max CAD

4 Stain and glaze program for IPS Empress CAD

5 Fusion/Crystallization program for the IPS e.max CAD-on technique

6 Characterization/glaze program for the IPS e.max CAD-on technique

7 Crystallization program for IPS e.max CAD Impulse

8 to 20 Individual Programs