SafeShield Safety Light Curtain Hardware User Manual

7

General Protective Notes and Protective Measures

The national/international rules and regulations apply to the

installation, use and periodic technical inspections of the safety light

curtain, in particular:

• Machine Directive 98/37/EEC

• Equipment Usage Directive 89/655/EEC

• The work safety regulations/safety rules

• Other relevant health and safety regulations

Manufacturers and operators of the machine with which the safety

light curtain is used are responsible for obtaining and observing all

applicable safety regulations and rules.

• The notices, in particular the test regulations (see “Test Notes”

on page 31) of these operating instructions (e.g. on use,

mounting, installation or integration into the existing machine

controller) must be observed.

• Changes to the configuration of the devices can modify the

protective function. After every change to the configuration you

must therefore check the effectiveness of the protective device.

The person who makes the change is also responsible for the

correct protective function of the device. When making

configuration changes, always use the password hierarchy

provided by Allen-Bradley Guardmaster to ensure that only

authorized persons make changes to the configuration.

• The tests must be carried out by specialist personnel or specially

qualified and authorized personnel and must be recorded and

documented to ensure that the tests can be reconstructed and

retraced at any time.

• The operating instructions must be made available to the

operator of the machine where the SafeShield safety light curtain

is installed. The machine operator is to be instructed in the use of

the device by specialist personnel and must be instructed to read

the operating instructions.

• The external voltage supply of the device must be capable of

buffering brief mains voltage failures of 20ms as specified in

EN 60204-1. Suitable power supplies are available as accessories

from Rockwell Automation.

Protection of the Environment

The SafeShield safety light curtain has been designed to minimize

environmental impact. It uses only a minimum of power and natural

resources.

Disposal

➢ Always dispose of unserviceable or irreparable devices in

compliance with local/national rules and regulations.

ATTENTION: Safety notes

Please observe the following procedures in

order to ensure the correct and safe use of

the SafeShield safety light curtain.

Product Description

This chapter provides information on the special features and

properties of the SafeShield safety light curtain. It describes the

construction and the operating principle of the device, in particular

the different operating modes.

➢ Please read this chapter before mounting, installing and

commissioning the device.

Special Features

SafeShield Safety Light Curtain

• Protection with either internal or external (realized on the

machine) restart interlock

• Connection for the reset button either in the control cabinet or

directly to the device

• Ability to connect an emergency stop button to the device

• External device monitoring (EDM)

• 2 beam codings possible in addition to noncoded operation

• Configurable signal output (ADO) for improved availability

• Status display with 7-segment display

• Range of functions can be expanded using the SafeShield function

module

• Blanking of several areas

• Blanking with tolerance of up to 2 beams

• Floating blanking

• Reduced resolution

• Object monitoring for areas with floating blanking

• Increased size tolerance for areas with fixed blanking

Operating Principle of the Device

Components of the Device

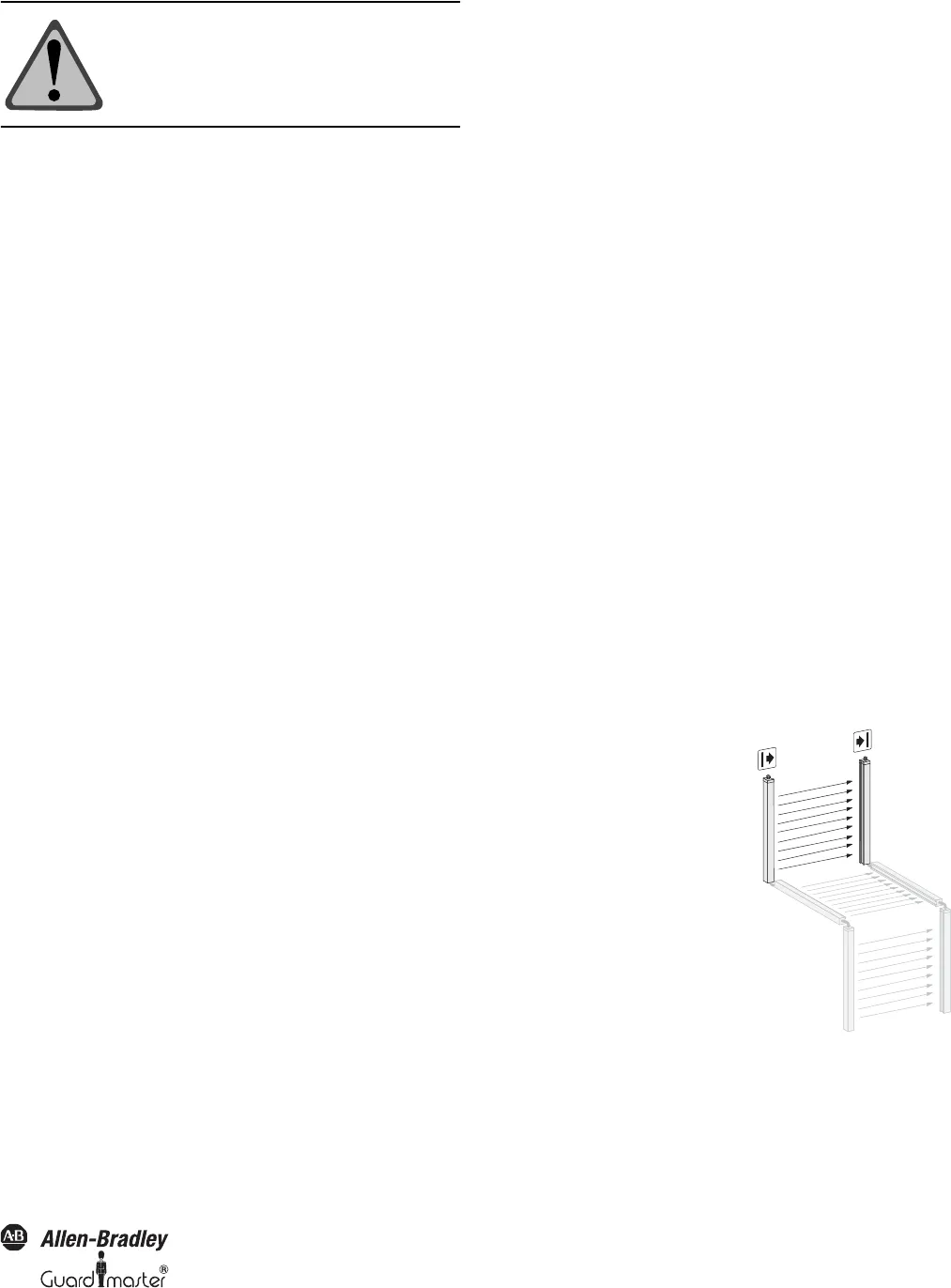

Figure 1: Components of the SafeShield safety light curtain

Please refer to “Technical Specifications” on page 35 for the data

sheet. Please refer to page 39 for dimensional drawings.

Host without cascading connection

or—in this case guest 1 connected—

with cascading connection.

Optional: 1. Guest system without

cascading connection or—in case

guest 2 connected—with cascading

connection.

Optional: 2. Guest system with or

without cascading connection.