- 9 -

APPLICATION

These Unit Coolers are designed for use with R12,

R22, R134a, R404A, R407A/B/C, R507 or R502

refrigerants.

At room temperatures above 34°F and evaporating

temps no lower than 27°F the air flowing through the

coil will accomplish the defrost. Temperatures of 34°F

and below (to -40°F) require positive defrosting.

(either Electric or Hot Gas).These models require the

use of (1) Time Clock (to initiate and terminate the

defrost cycle). (2) Fan-Delay thermostat (to prevent

evaporator fans from starting up right after defrost and

blowing water on to fan blades, guards and floor) (3)

Defrost Termination Control (to prevent unnecessary

prolonged heating and steaming of the coil once all

the ice and frost has melted).

The coil must not be exposed to any abnormal atmos-

pheric or acidic environments. This may result in

corrosion to the cabinet and possible coil failure

(leaks). (Consult manufacturer for optional baked on

phenolic protective coatings).

INSTALLATION

The installation and start-up of Unit Coolers should

only be performed by qualified refrigeration mechan-

ics.

This equipment should be installed in accordance

with all applicable codes, ordinances and local by-

laws.

INSPECTION

Inspect all equipment before unpacking for visible

signs of damage or loss. Check shipping list against

material received to ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must

make any claim necessary against the transportation

company. Shipping damage or missing parts, when

discovered at the outset, will prevent later unneces-

sary and costly delays.

If damage or loss during transport is evident,

make claim to carrier, as this will be their respon-

sibility, not the manufacturer’s.

Should carton be damaged, but damage to equip-

ment is not obvious, a claim should be filed for “con-

cealed damage” with the carrier.

IMPORTANT: The electrical characteristics of the unit

should be checked at this time to make sure they

correspond to those ordered and to electrical power

available at the job site.

Save all shipping papers, tags and instruction sheets

for reference by installer and owner.

LOCATION

The unit location in the room should be selected to

ensure uniform air distribution throughout the entire

space to be refrigerated. Be sure that the unit does

not draw air in, or blow directly out, through an

opened door and that the product does not obstruct

the free circulation of air. Allow a minimum of 24”

clearance at each end and behind the unit.

The Unit Coolers draw air through the coil and dis-

charge air from the fan side.

Consideration should be given to the coil location in

order to minimize the piping run length to the con-

densing unit and floor drain.

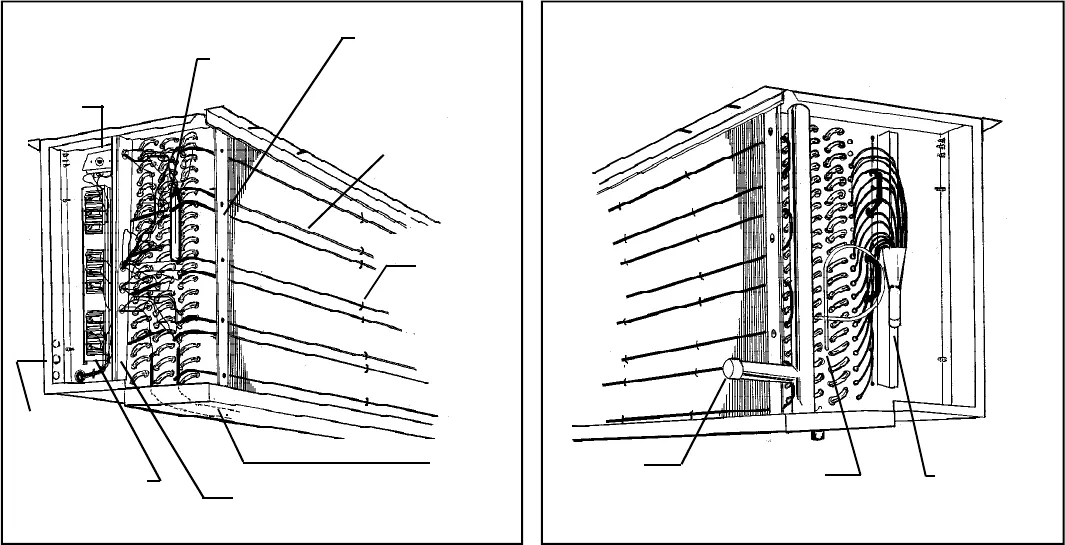

ELECTRICAL VIEW

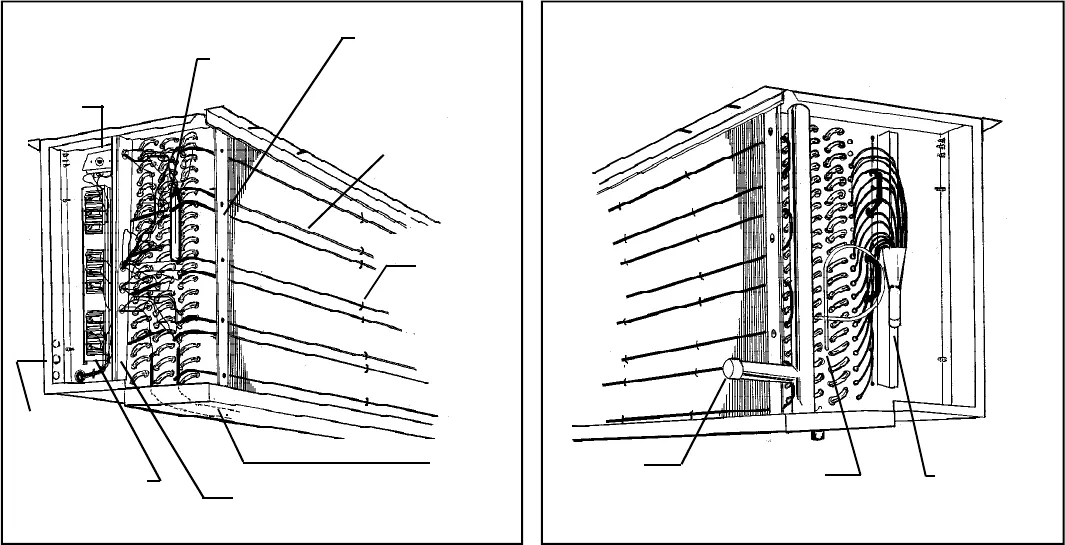

PIPING VIEW

ADJUSTABLE DEFROST

TERMINATION

CONTROL

DEFROST

THERMOSTAT

BULB

REAR HEATER SLOT

COVER PLATE

(REMOVE 5 SCREWS)

DRAIN PAN

HEATER

ELEMENT(1)

TERMINAL BLOCKS

DEFROST CONTROL (TOP)

HEATERS (MIDDLE)

FAN MOTORS (BOTTOM)

ENTERING

SERVICE

KNOCK-OUTS

FRONT HEATER

SLOT COVER PLATE

(REMOVE 5 SCREWS)

HEATER

SPRING

CLIPS

DEFROST HEATER

ELEMENTS (6)

(4 0N AIR-ENTERING SIDE,

2 ON LEAVING AIR-SIDE)

TX VALVE

CONNECTION

EXTERNAL

EQUALIZER

CONNECTION

SUCTION

CONNECTION