41

conditions, the engine RPM is the controlling factor in determining the

correct propeller blade pitch. To obtain peak performance, the engine RPM

at full throttle should be in the full throttle operating range specified by the

engine manufacturer. If engine RPM is below that range, install a prop of

reduced pitch to increase engine RPM. If engine RPM is above the

recommended range, install a prop of increased pitch.

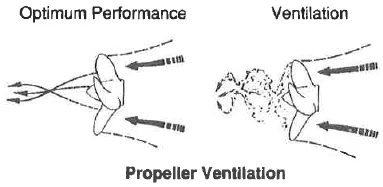

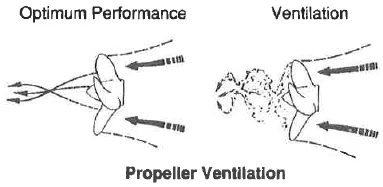

VENTILATION: Ventilation occurs when air from the water's surface or

exhaust gases from the exhaust outlet are drawn into propeller blades. The

normal water load is reduced and the propeller over-revs, losing much of its

thrust. However, as the propeller momentarily over-revs, this brings on

massive cavitation (see below), which can further "unload" the propeller

and stop all forward thrust. It continues until the propeller is slowed down

enough to allow the bubbles to surface. This action most often occurs in

turns, particularly when trying to plane in a sharp turn or with an excessively

trimmed-out engine or drive unit. With Pontoon boats ventilation can be

caused by an improperly loaded boat. If all passengers are in the front bow

benches ventilation can happen. Passengers should be situated evenly

throughout the boat. Passengers should not sit in front recliner chairs or

front fishing chairs while the boat is underway. Not only can this cause

ventilation, but the lower walls cause this activity to be unsafe. Boats that

have rear fishing chairs are particularly susceptible to ventilation if passen-

gers are not situated evenly throughout the boat. Ventilation can also occur

if the propeller's pitch

causes the engine to

operate above or below its

suggested RPM range.

CAVITATION: Depending

upon water temperature,

when the pressure on the

leading edge of a propeller

blade drops enough, water vapor bubbles are created by "boiling." As the

water vapor moves downstream into higher pressure, it collapses back into

liquid releasing energy that chips away at the blades, causing a "cavitation

burn" or erosion of the metal. Initial cause of the low pressure may be nicks

in the leading edge, too much cup, improper polishing, etc. If cavitation is

caused by a damaged propeller, have it reconditioned or replaced.

ENGINE OVERSPEED: This can occur when a propeller of too Iowa pitch is

used or engine is set at wrong tilt angle or height on transom. Over-

speeding can cause damage to the powerplant in the form of broken

connecting rods, crank shafts and valve train components (in four-cycle

engines). Broken parts can be thrown from the engine at high velocity and

cause injury or damage. A tachometer should be used to monitor engine

speed and to avoid "over-revving." If you're using a low-pitch propeller for

better load carrying or water skiing performance, be careful when operating

under light load conditions to avoid over-speeding the engine.